Method of raising magnetic performance of nanometer magnetic metal material

A magnetic metal nanotechnology, magnetic nanotechnology, applied in the direction of magnetic materials, magnetic objects, electrical components, etc., can solve the problems of not meeting the existing and potential application requirements, and achieve the improvement of microwave absorption efficiency, magnetic performance, and magnetic properties. The effect of recording density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0014] Raw material type: nano iron particles

[0015] Geometric shape and scale: spherical particles with an average particle size of 50nm

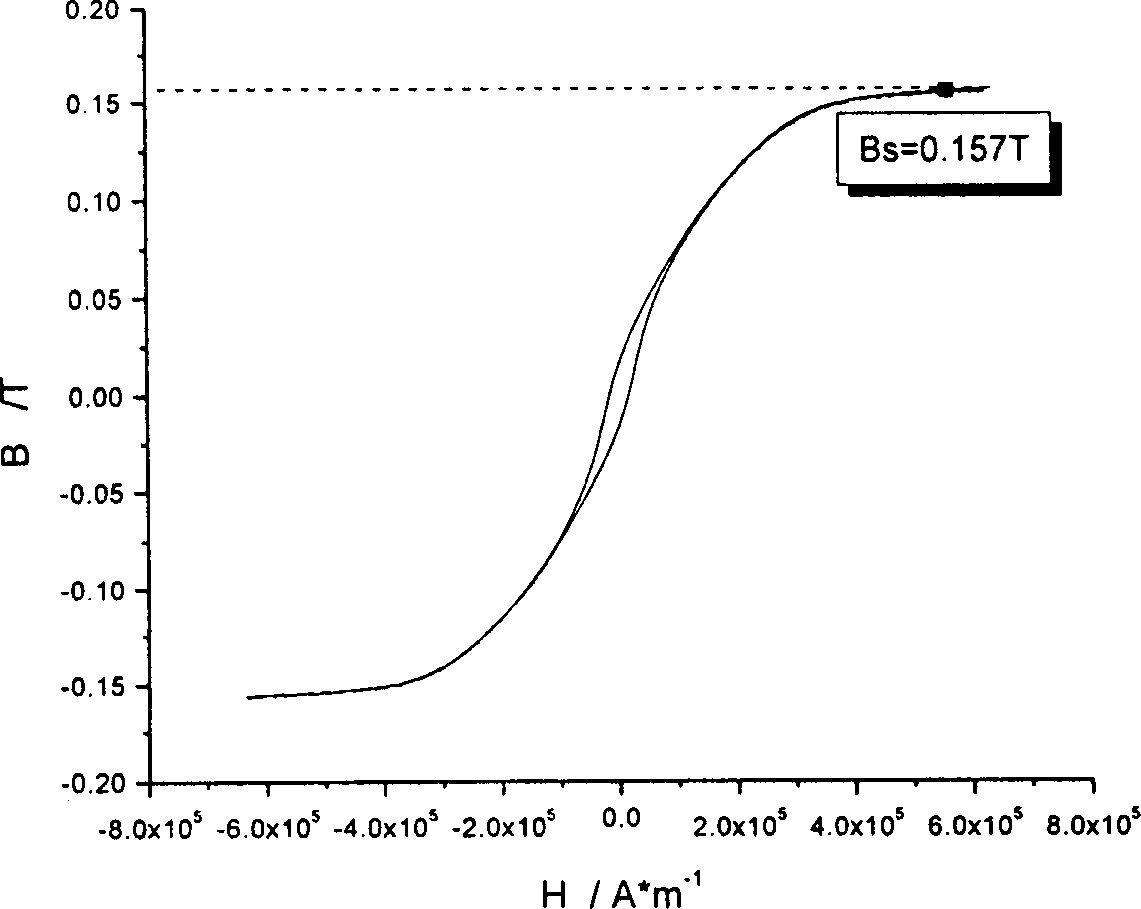

[0016] Original saturation magnetic induction Bs: 0.157T

[0017] Heating method: open resistance furnace

[0018] Heating temperature: 473K

[0019] Cooling method and temperature: liquid nitrogen cooling to 77.35K

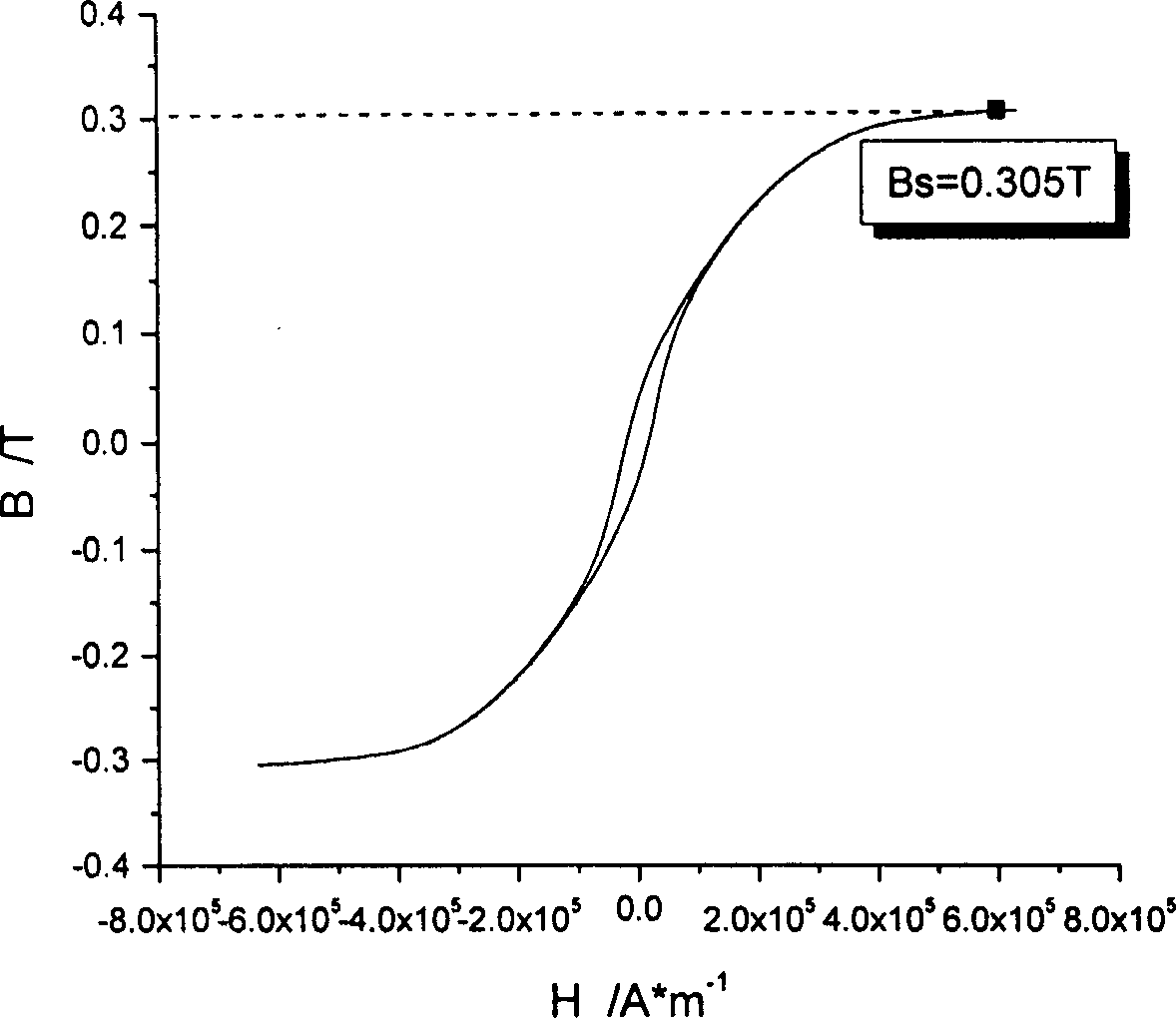

[0020] Saturation magnetic induction intensity Bs after treatment: 0.305T

[0021] The original saturation magnetic induction measured in this example and the processed saturation magnetic induction are given by figure 1 , figure 2 shown.

example 2

[0023] Raw material type: Co-Ni nano-alloy particles, Co:Ni is 1:4

[0024] Geometric shape and scale: spherical particles with an average particle size of 40nm

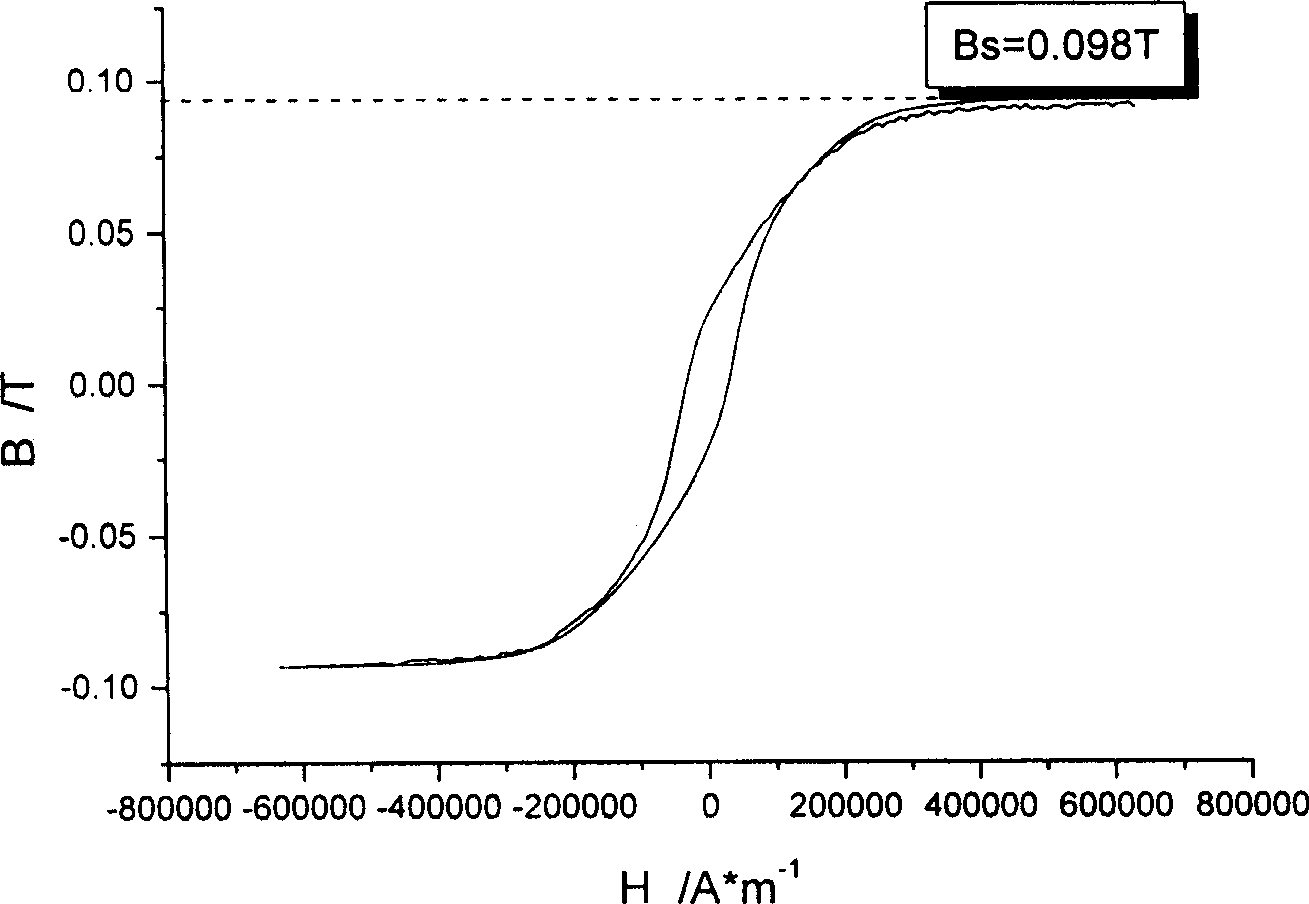

[0025] Original saturation magnetic induction Bs: 0.098T

[0026] Heating method: open resistance furnace

[0027] Heating temperature: 633K

[0028] Cooling method and temperature: liquid nitrogen cooling to 77.35K

[0029] Saturation magnetic induction intensity Bs after treatment: 0.190T

[0030] The original saturation magnetic induction measured in this example and the processed saturation magnetic induction are given by image 3 , Figure 4 shown.

example 3

[0032] Raw material type: nano-iron particles Geometric shape and size: spherical particle average particle size 50nm Original saturation magnetic induction Bs: 0.157T Heating method: open resistance furnace heating temperature: 473K Intensity Bs: 0.280T Example 4 Type of raw material: Nano-nickel particles Geometric shape and size: spherical particles with an average particle size of 50nm Original saturation magnetic induction intensity Bs: 0.081T Heating method: open resistance furnace Heating temperature: 523K Cooling method and temperature: liquid helium Saturation magnetic induction intensity Bs after cooling to 10K: 0.170T Example 5 Raw material type: nano-cobalt particles Geometric shape and size: spherical particles with an average particle size of 50nm Original saturation magnetic induction intensity Bs: 0.211T Heating method: open resistance furnace Heating temperature: 823K Cooling method and temperature: dry ice cooling to 195K saturation magnetic induction intensit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com