Biological reactor

A bioreactor and tank technology, applied in bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, biochemical equipment, etc., can solve the problem of bacteria entering the reactor and the seal of the shaft seal is not tight , contamination of cultures and other issues, to achieve the effect of convenient bearing installation, convenient maintenance, and not easy to infect bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with drawings and embodiments.

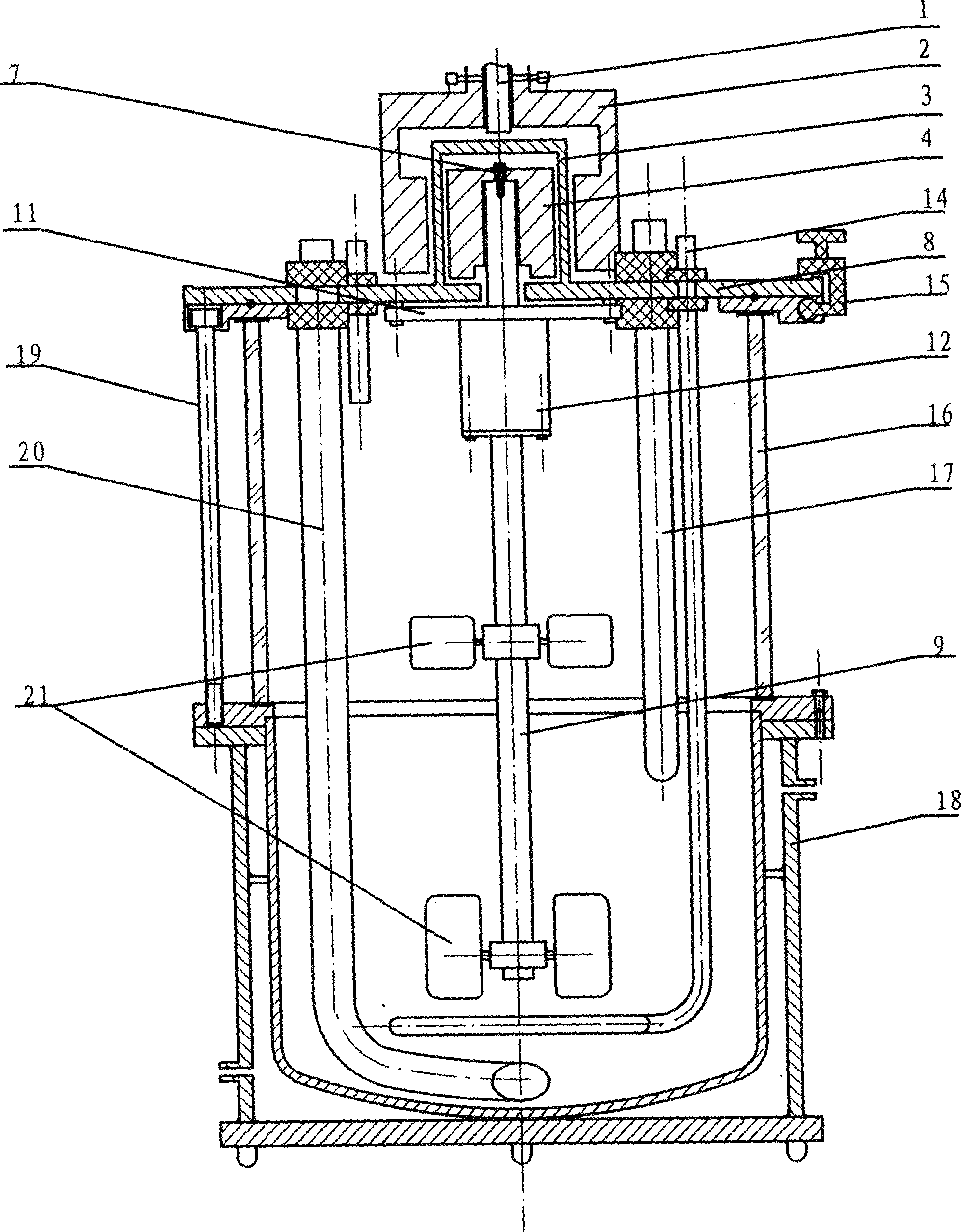

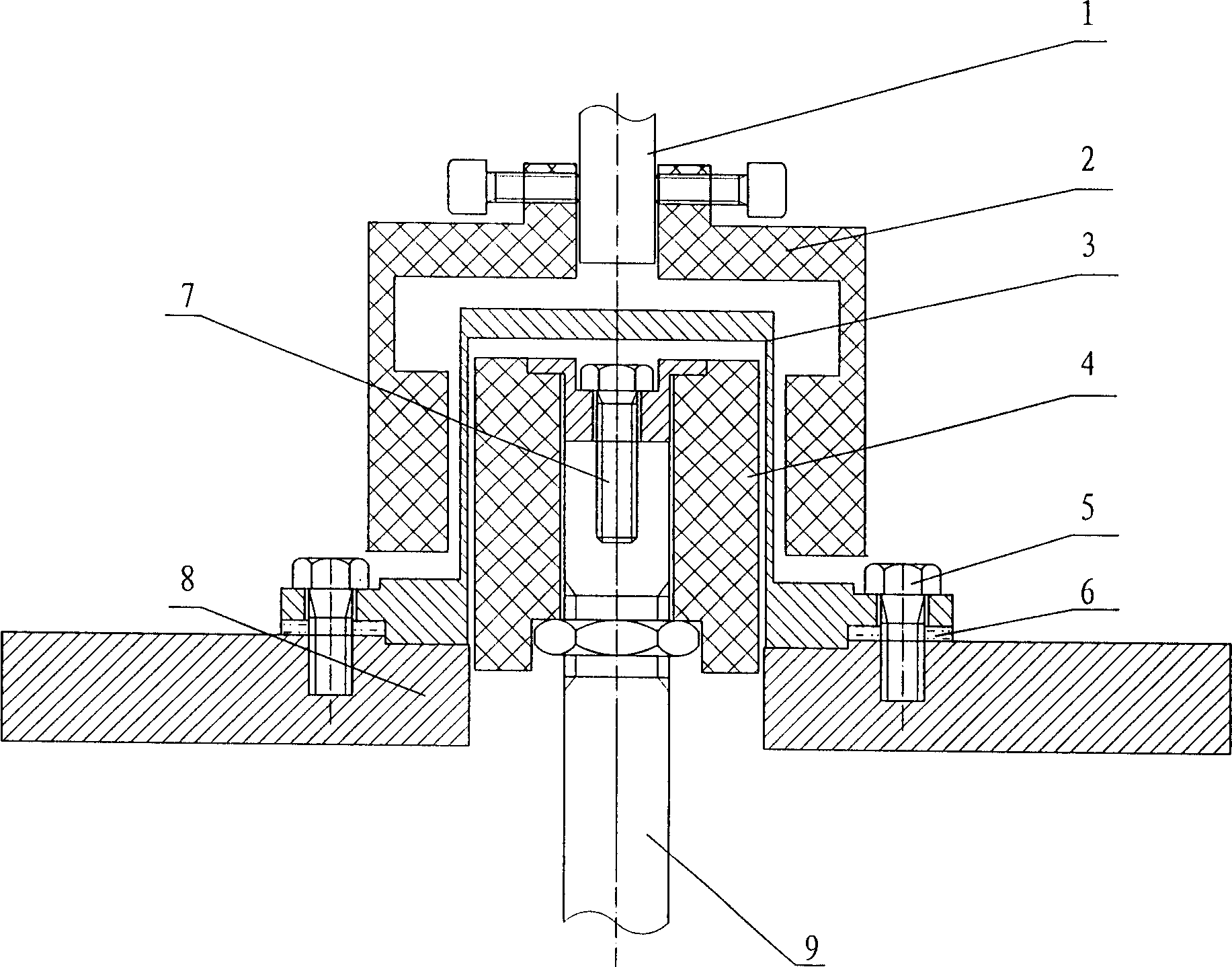

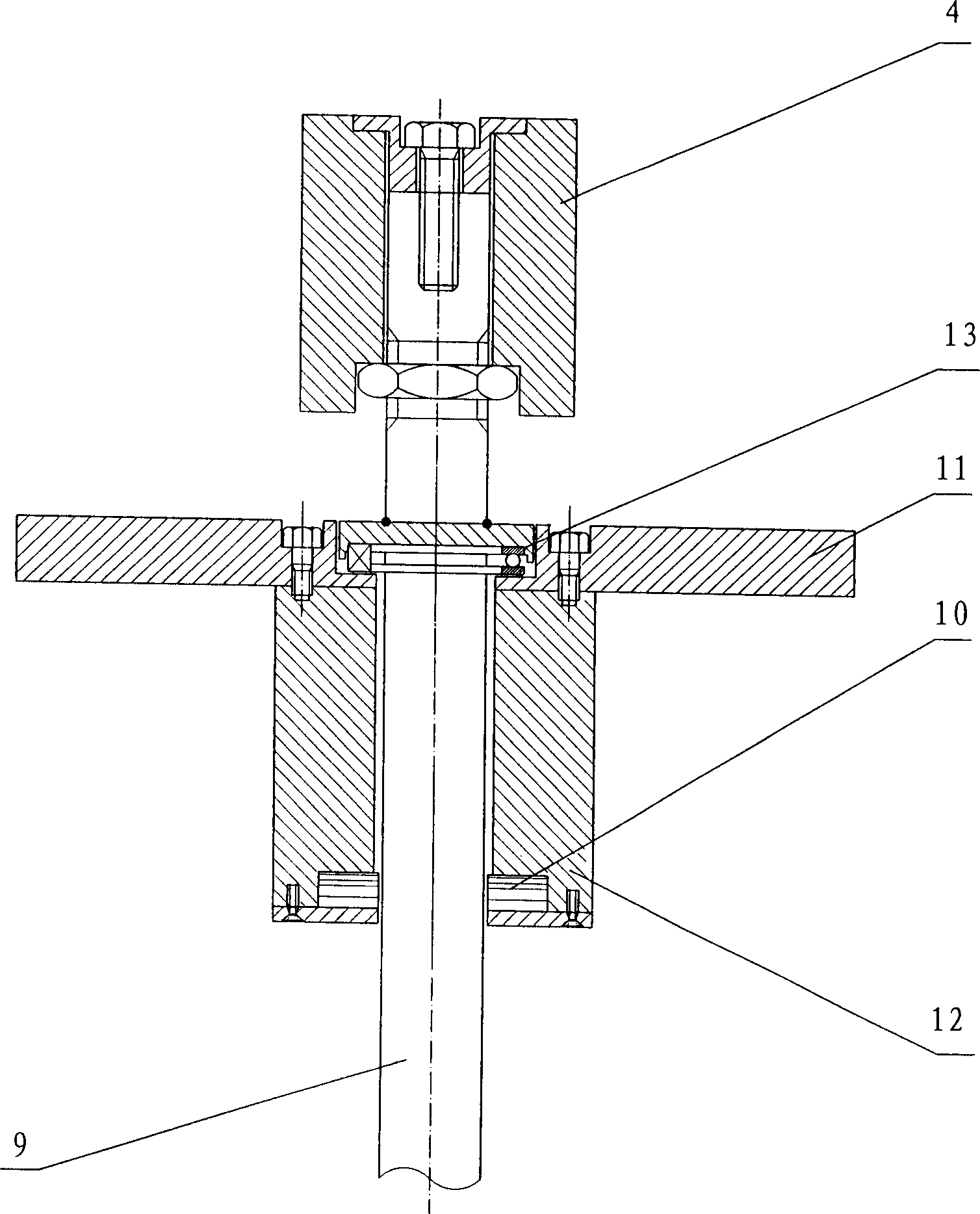

[0016] Such as figure 1 As shown, the magnetic coupling transmission stirring bioreactor is mainly composed of motor shaft 1, outer magnetic cylinder 2, shaft top cover 3, inner magnetic cylinder 4, inner magnetic cylinder fixing bolt 7, reactor upper cover plate 8, stirring shaft 9, Bearing box fixing plate 11, air inlet pipe 14, flange 15, glass outer wall 16, temperature sensor jack 17, jacket 18, pull rod 19, discharge pipe 20 and stirring paddle 21 constitute. Wherein, it should be emphasized that a certain gap should be reserved around the stirring shaft 9 in the center of the reactor top cover plate 8, and a certain gap should be left between the bearing box fixing plate 11 and the reactor top cover plate 8, so that During sterilization, high-pressure steam can enter the shaft top cover 3 through the pores, thereby completely killing miscellaneous bacteria. Oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com