Cathode reduction process for treating surface of porous silicon

A technology of surface treatment and porous silicon, applied in post-processing, post-processing details, chemical instruments and methods, etc., can solve problems such as unsuitable for industrial production, difficult control accuracy, complex equipment, etc., to achieve convenient operation, easy precision control, The effect of simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

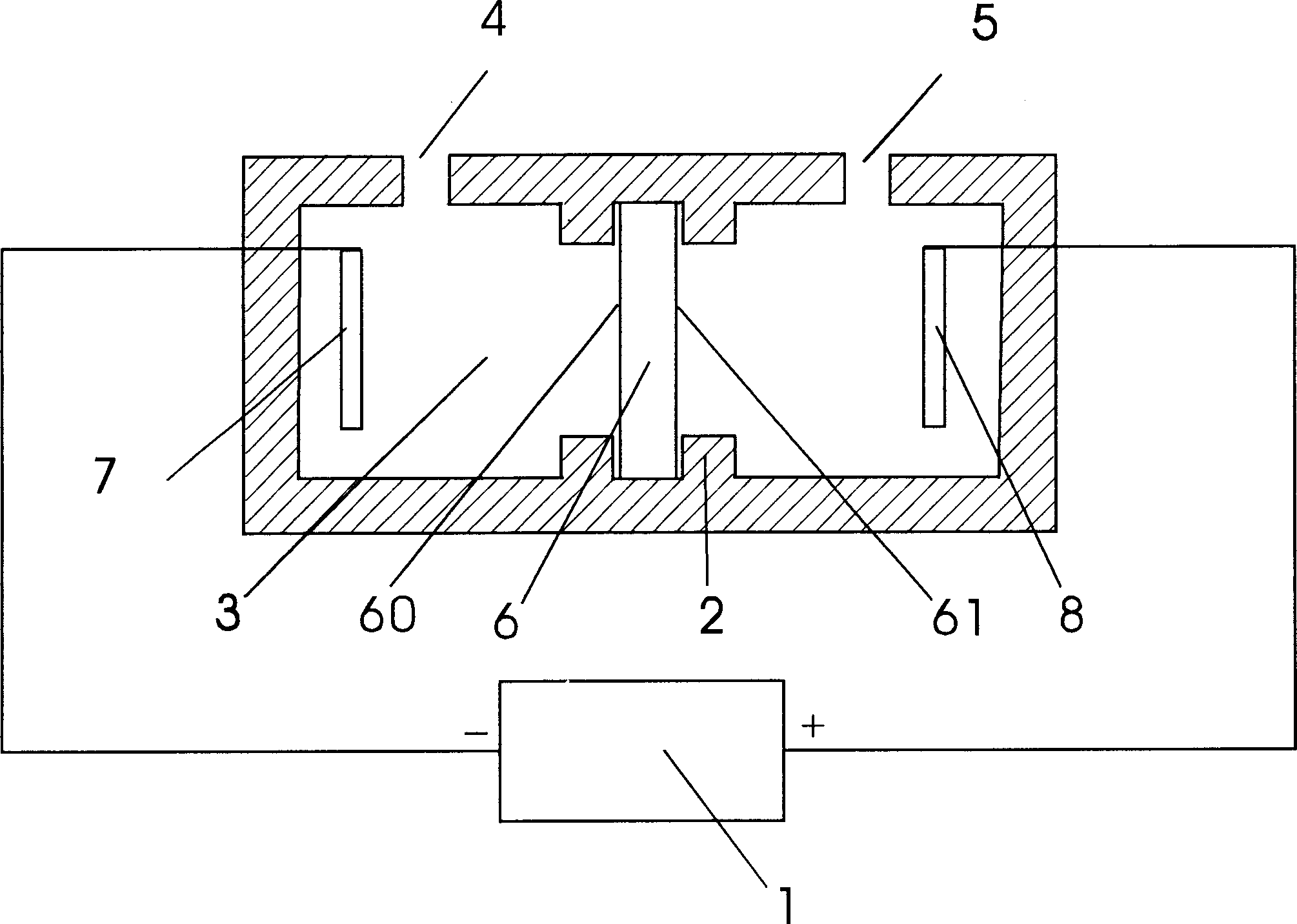

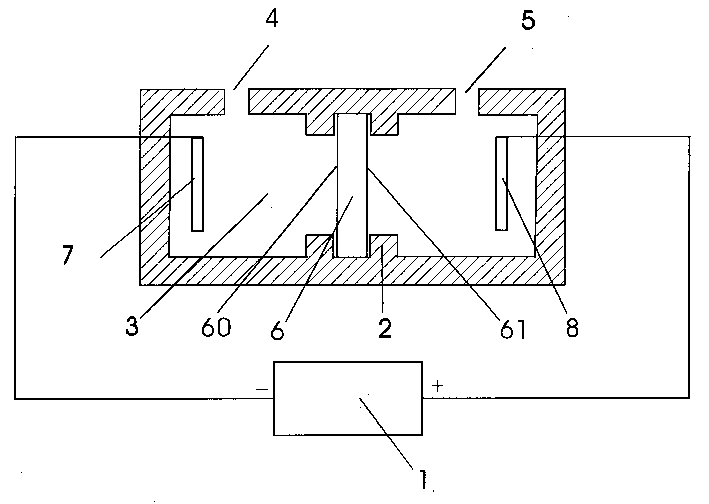

Method used

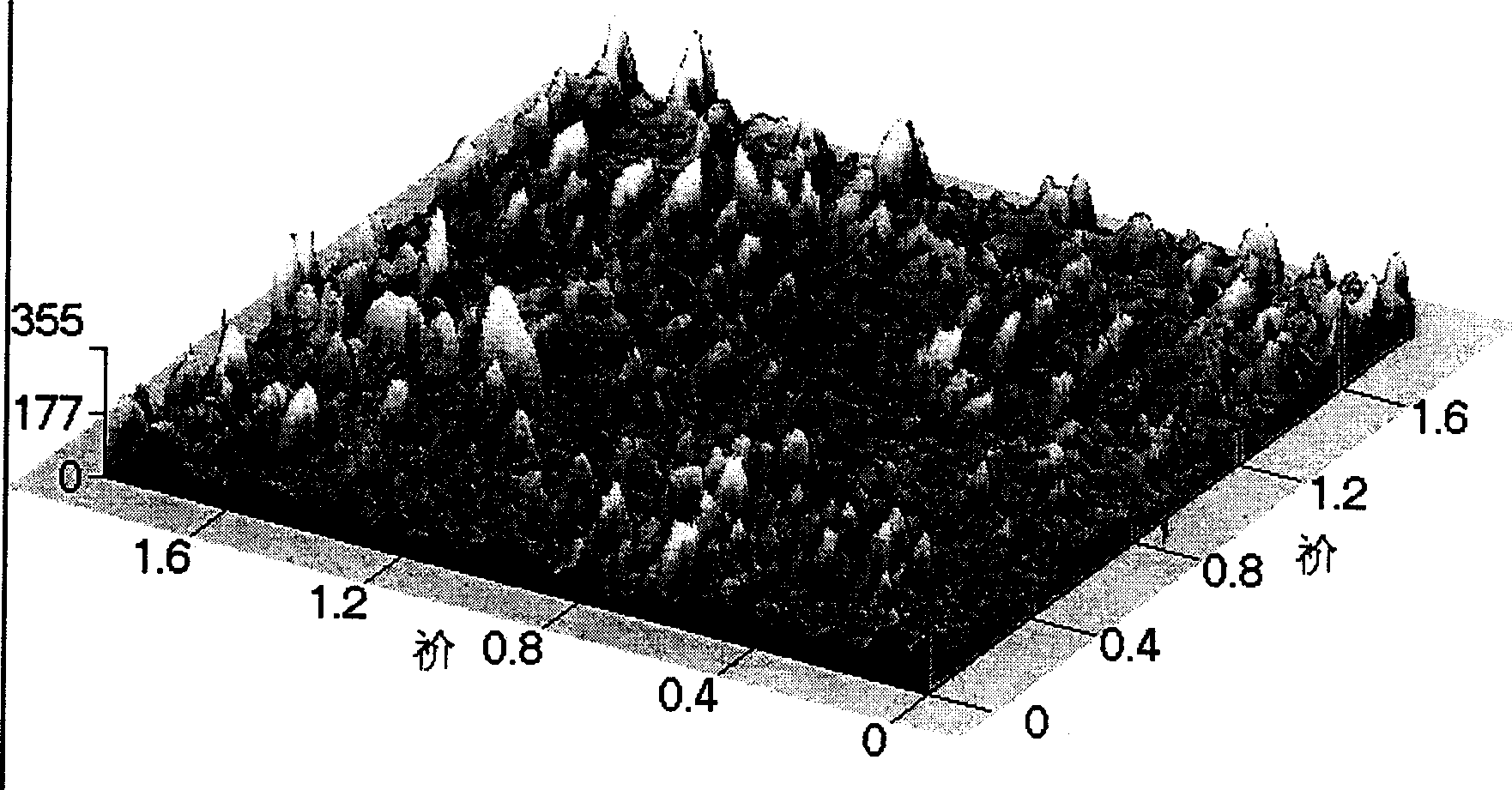

Image

Examples

Embodiment 1

[0023] Cathodic reduction surface treatment technology of embodiment 1 porous silicon

[0024] Cathodic reduction surface treatment process of porous silicon:

[0025] Current density of reverse current: 1.2mAcm -2

[0026] Reverse feed time: 50min

[0027] Porous silicon drying process: cleaning time: 10min

[0028] Drying method: one of four drying methods

[0029] The porous silicon prepared in this embodiment has no hair-like substances, and its surface is smooth and bright as a mirror, and can be stored in the air for a long time. Stored for more than 30 days, there is no tendency to deteriorate. I have done gold plating, photolithography, and made partial porous silicon, and the results are very satisfactory.

Embodiment 2

[0030] Cathodic reduction surface treatment technology of embodiment 2 porous silicon

[0031] Cathodic reduction surface treatment process of porous silicon:

[0032] Current density of reverse current: 2mAcm -2

[0033] Reverse feed time: 30min

[0034] Porous silicon drying process: cleaning time: 15min

[0035] Drying method: one of four drying methods

[0036] The porous silicon prepared in this embodiment has no hair-like substances, and its surface is smooth and bright as a mirror, and can be stored in the air for a long time. Stored for more than 30 days, there is no tendency to deteriorate. I have done gold plating, photolithography, and made partial porous silicon, and the results are very satisfactory.

Embodiment 3

[0037] Cathodic reduction surface treatment technology of embodiment 3 porous silicon

[0038] Cathodic reduction surface treatment process of porous silicon:

[0039] Current density of reverse current: 10mAcm -2

[0040] Reverse feed time: 6min

[0041] Porous silicon drying process: cleaning time: 15min

[0042] Drying method: one of four drying methods

[0043] The porous silicon prepared in this embodiment has no hair-like substances, and its surface is smooth and bright as a mirror, and can be stored in the air for a long time. Stored for more than 30 days, there is no tendency to deteriorate. I have done gold plating, photolithography, and made partial porous silicon, and the results are very satisfactory.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com