One-dimensional hydrogen-storing carbon nano-material etched via microwave plasma and its prepn process

A technology of microwave plasma and hydrogen storage materials, applied in chemical instruments and methods, other chemical processes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

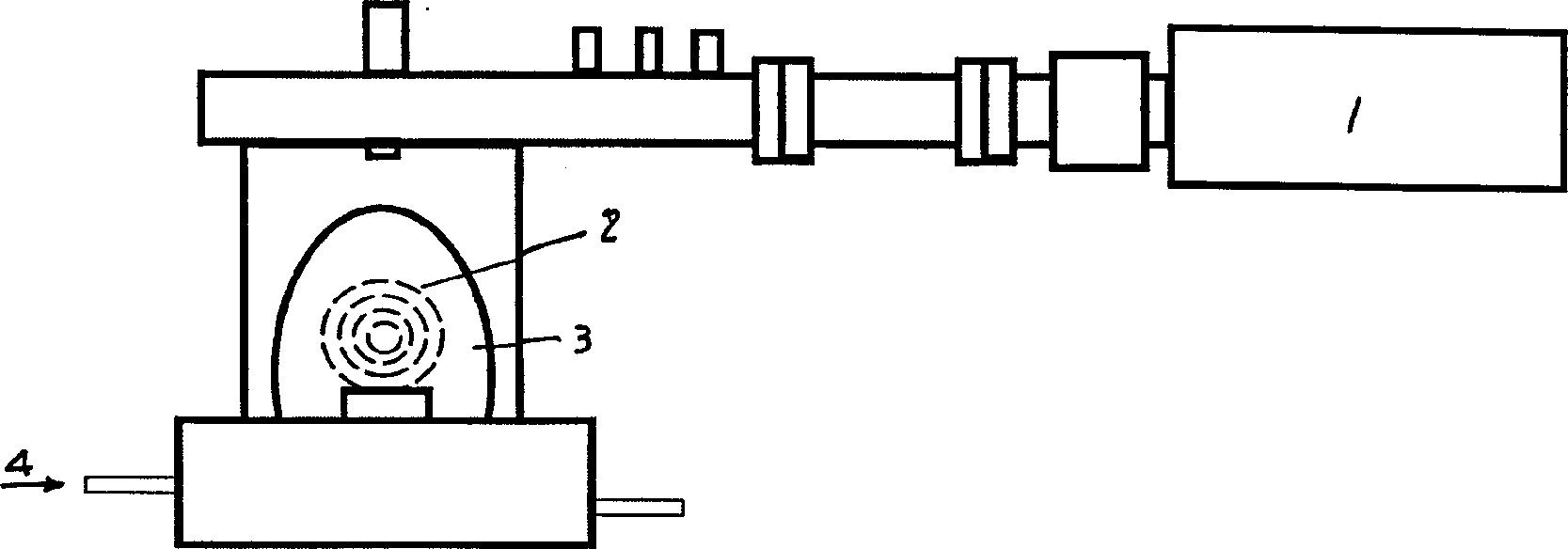

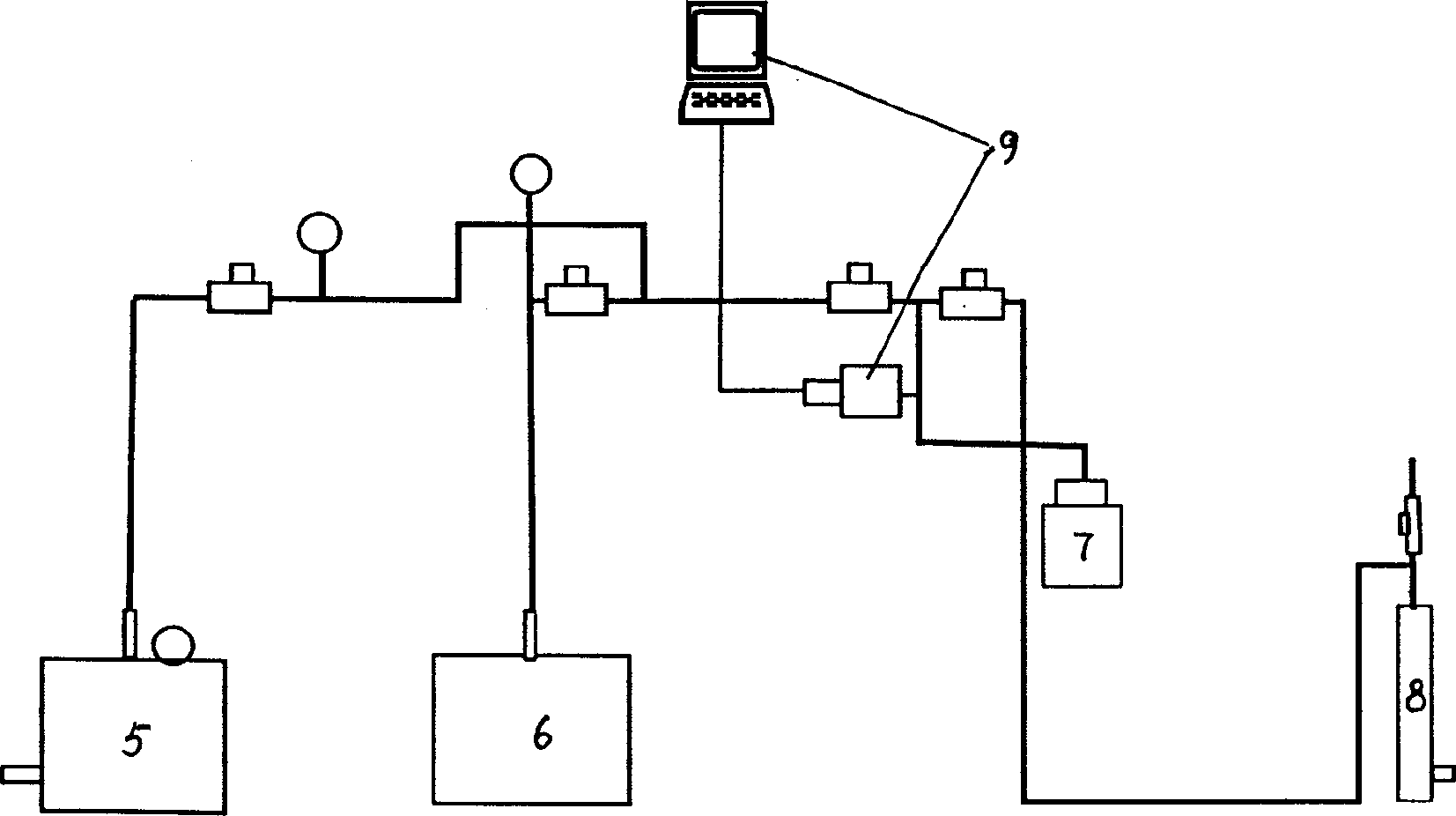

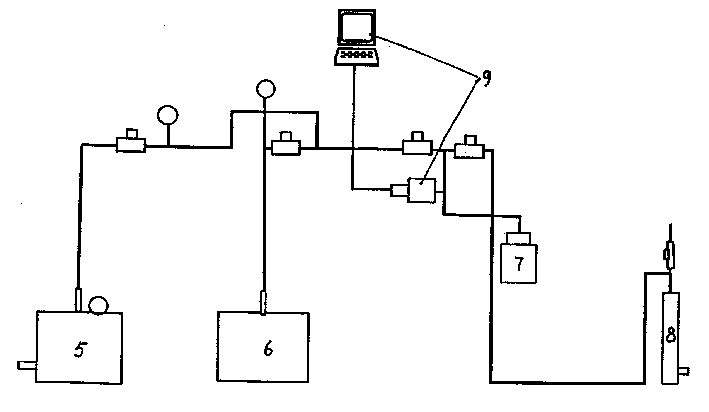

[0023] Implementing devices such as figure 1 , figure 2 shown.

[0024] The single-wall carbon nanotube is prepared by a hydrogen arc discharge method, and the prepared single-wall carbon nanotube has a purity of 60%, a tube diameter of 1-40 nm, and a tube length of 10-100 μm. After it was ground, it was placed in 2M NaOH solution, heated to reflux and ultrasonically oscillated for 1 h, then washed with deionized water and dried. The dried single-walled carbon nanotubes were treated with mixed acid (concentrated H 2 SO 4 : Concentrated HNO 3 =3:1) oxidation treatment for 1 h, washed with deionized water and dried. The above-mentioned pretreated single-walled carbon nanotubes were calcined in argon at 1000° C. for 2 h, then soaked in dilute sulfuric acid solution for 5 h, washed with deionized water, and dried. Under the conditions of hydrogen purity of 99.999%, initial pressure of 7Mpa, and room temperature, the hydrogen storage capacity of the defunctionalized single-w...

Embodiment 2

[0026] Multi-walled carbon nanotubes are prepared by catalytic cracking. The prepared multi-walled carbon nanotubes have a purity of 75 percent, a tube diameter of 10-80 nm, and a tube length of 20-100 μm or more. The pretreatment, defunctionalization treatment, microwave plasma etching process and hydrogen storage test conditions of the multi-walled carbon nanotubes are the same as in Example 1. Tests show that the hydrogen storage capacity of the defunctionalized multi-walled carbon nanometer is 1 wt%, and the hydrogen storage capacity of the etched multi-walled carbon nanotube is 2.5 wt%.

Embodiment 3

[0028] Carbon nanofibers are prepared by catalytic cracking. The prepared nano-carbon fiber has a purity of 78 percent, a tube diameter of 80-100 nm, and a tube length of more than 0.1 mm. The pretreatment, defunctionalization, microwave plasma etching process and hydrogen storage test conditions of the carbon nanofibers are the same as in Example 1. Tests show that the hydrogen storage capacity of the defunctionalized nano-carbon fiber is 2.5 wt%, and the hydrogen storage capacity of the etched nano-carbon fiber is 3.8 wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com