Circular loading shear apparatus for observing earth and structural member contact face mechanical property

A technology of cyclic loading and mechanical properties, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of difficult normal boundary conditions of the contact surface, not fully considering the characteristics of the contact surface, and difficult to simulate the actual mechanical behavior, etc. Achieve the effect of improving test and measurement accuracy, good effect and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

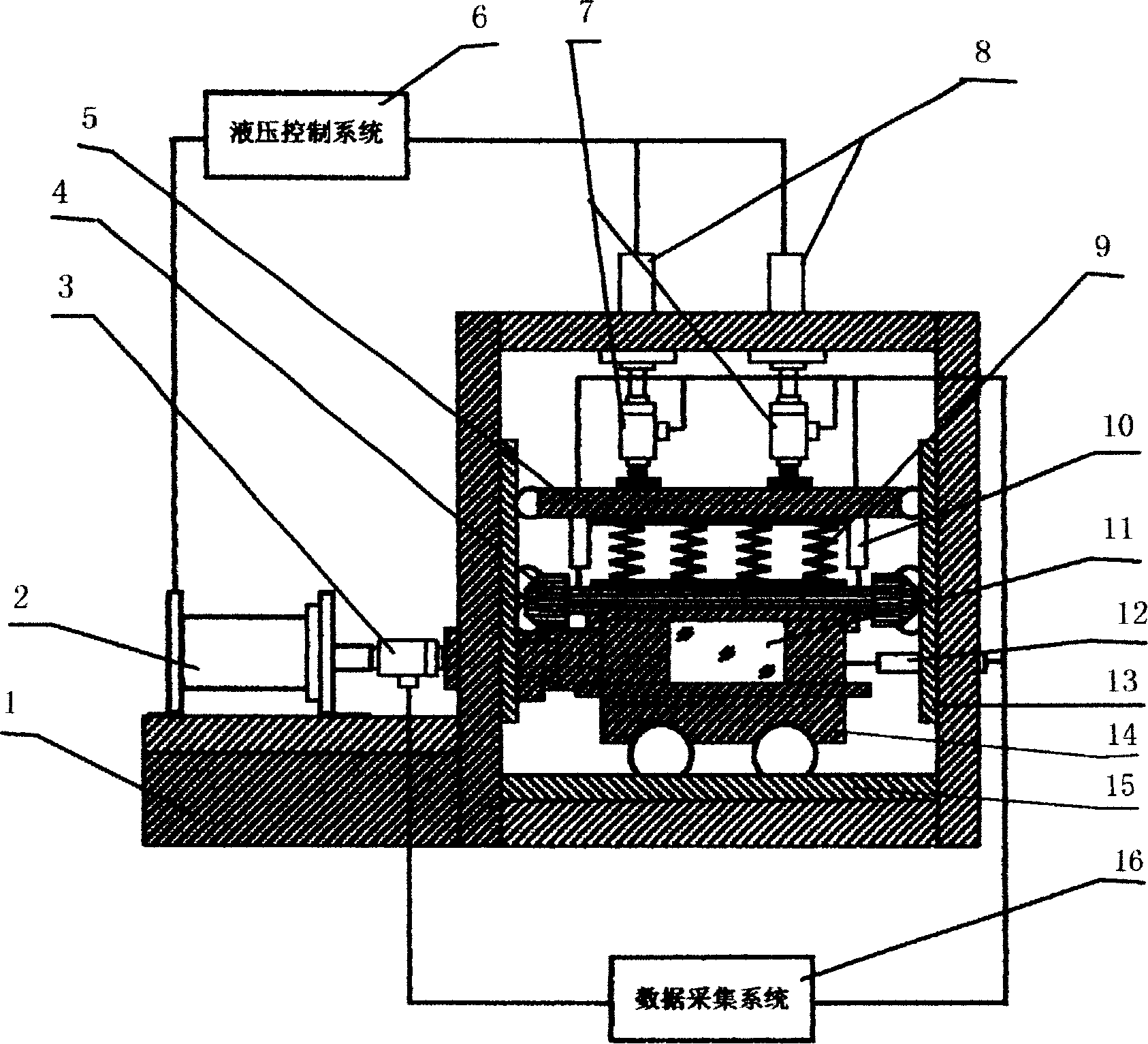

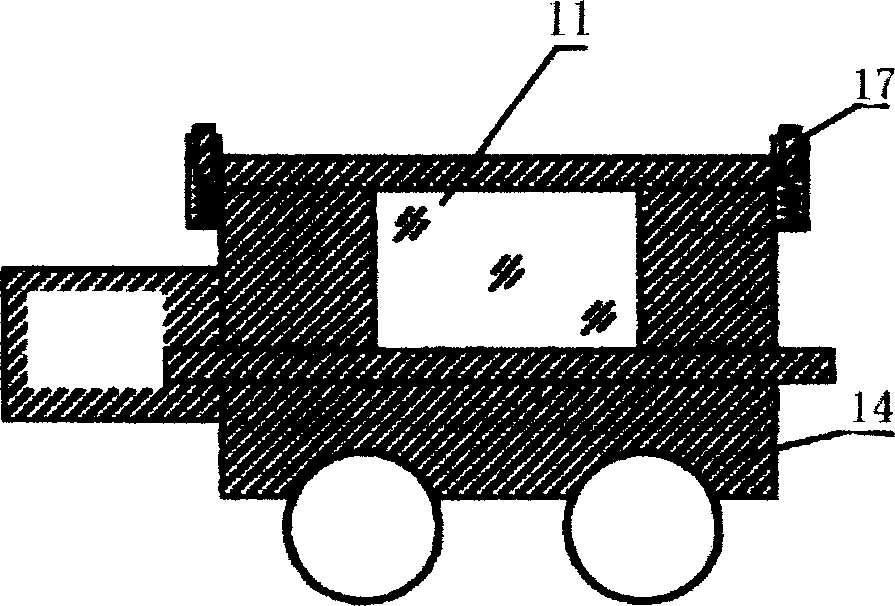

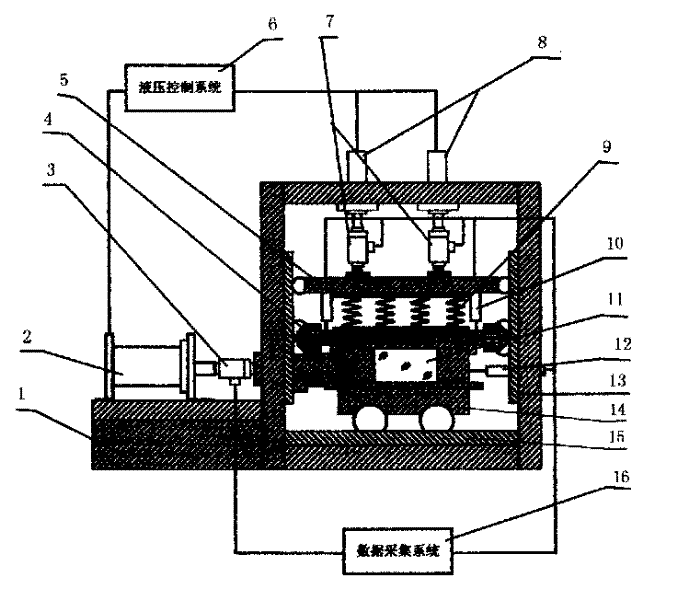

[0010] figure 1 Shown is a schematic diagram of the structure of the cyclic loading shear instrument for observing the mechanical properties of the contact surface between the soil and the structure. The shear instrument is mainly composed of a support, a soil container vehicle, a hydraulic loading and control system, a normal boundary control unit, and a data acquisition system , the soil container vehicle 14 is placed on the horizontal track 15 on the inner bottom surface of the support 1, the test soil is filled in the vehicle, the structural panel 4 is placed flat on it, and the upper wing plate 5 is snapped into the vertical tracks 13 on both sides of the support 1 Inside, a normal boundary control unit 9 and a vertical displacement sensor 10 are installed between the upper wing plate 5 and the structural panel 4, and the vertical load sensor 7 is installed on the upper wing plate 5 and the vertical hydraulic pressure sensor fixed on the support 1. The cylinder 8 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com