Intelligent blast furnace smelt controlling system

A blast furnace smelting and intelligent control technology, applied to blast furnaces, blast furnace details, blast furnace parts, etc., can solve problems such as backward means of data information transmission, complicated situations, and failure to establish a microcomputer LAN in ironworks, so as to improve the level of informatization The effect of improving the level of scientific management, improving the level of intellectual labor automation, and reducing the intensity of mental labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

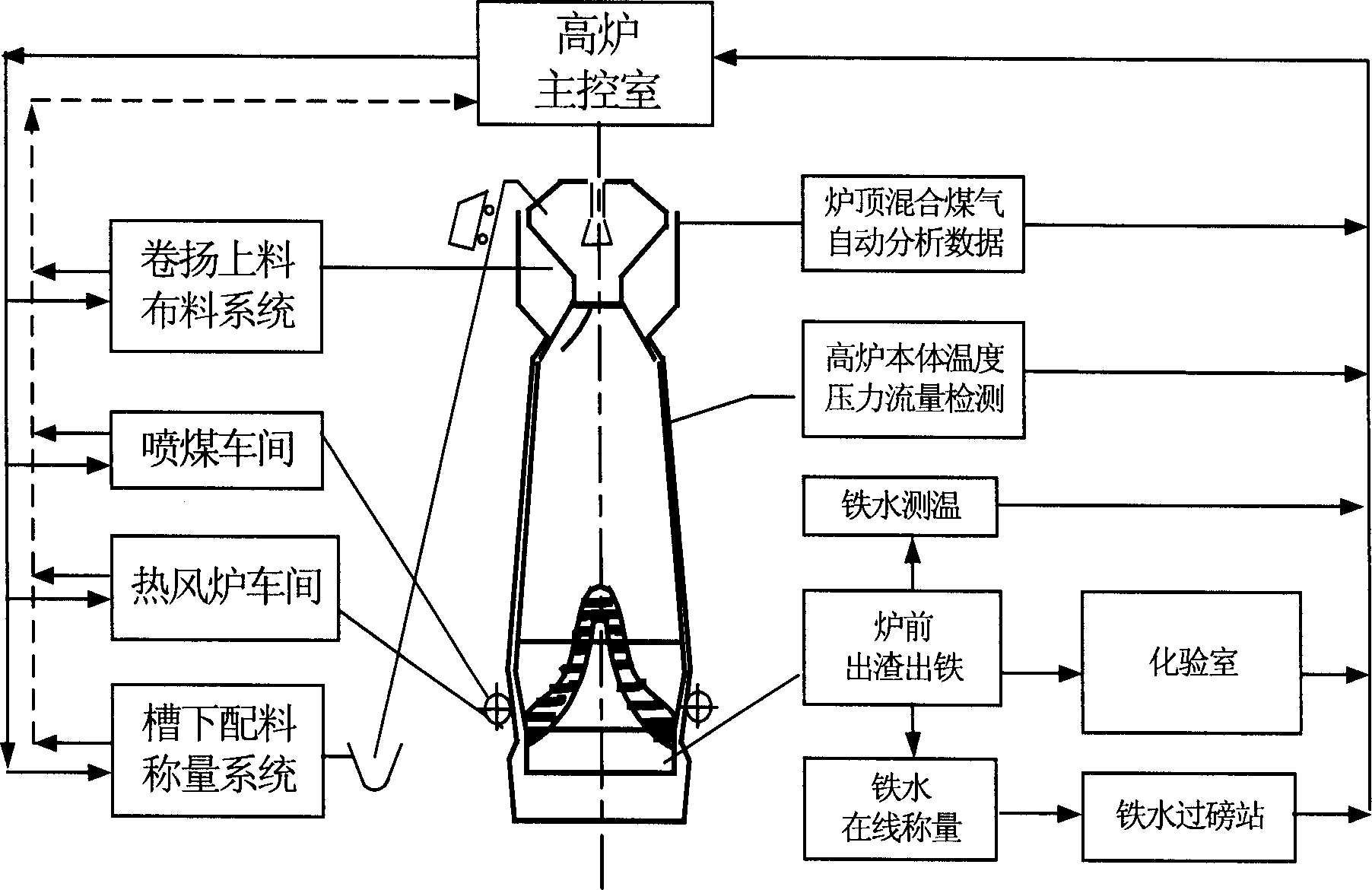

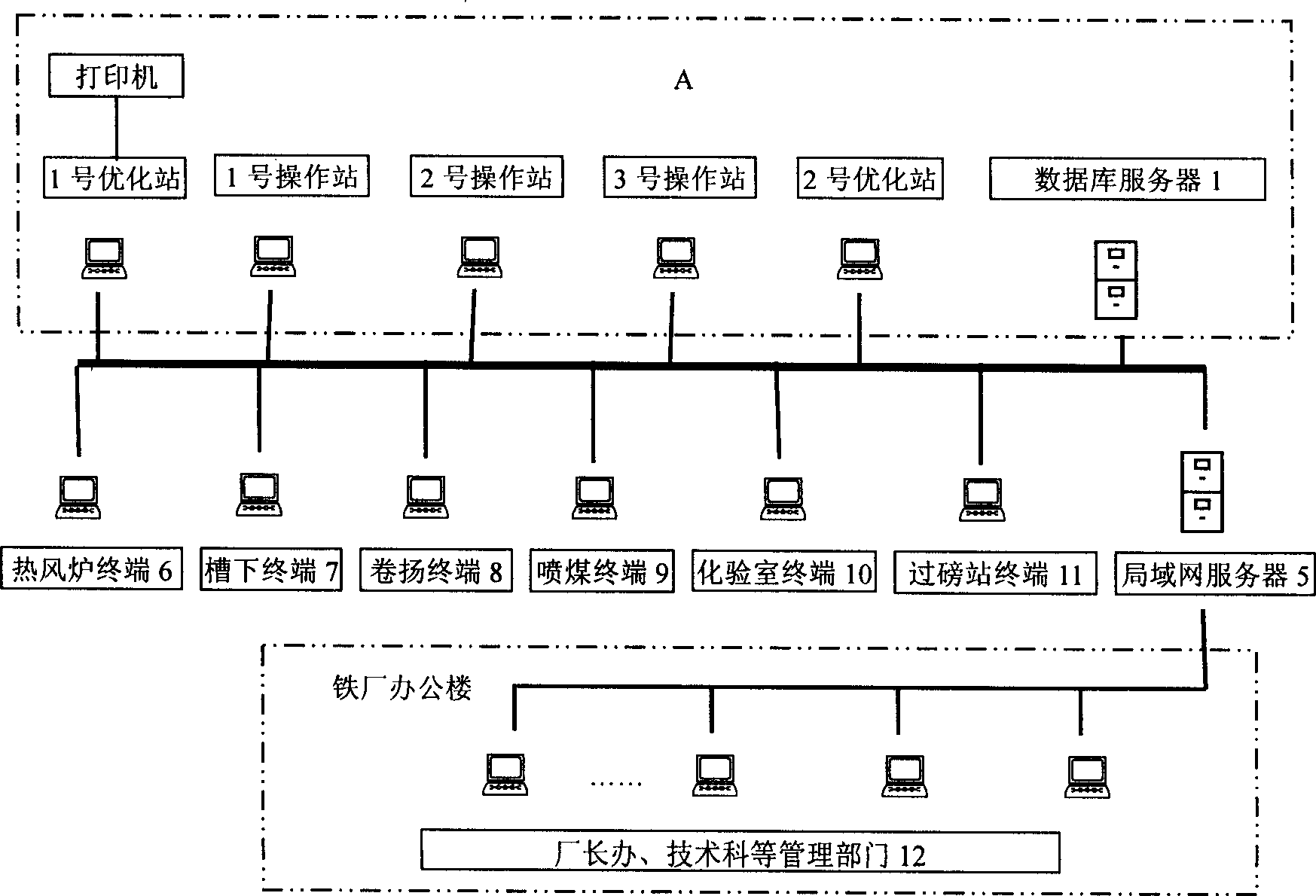

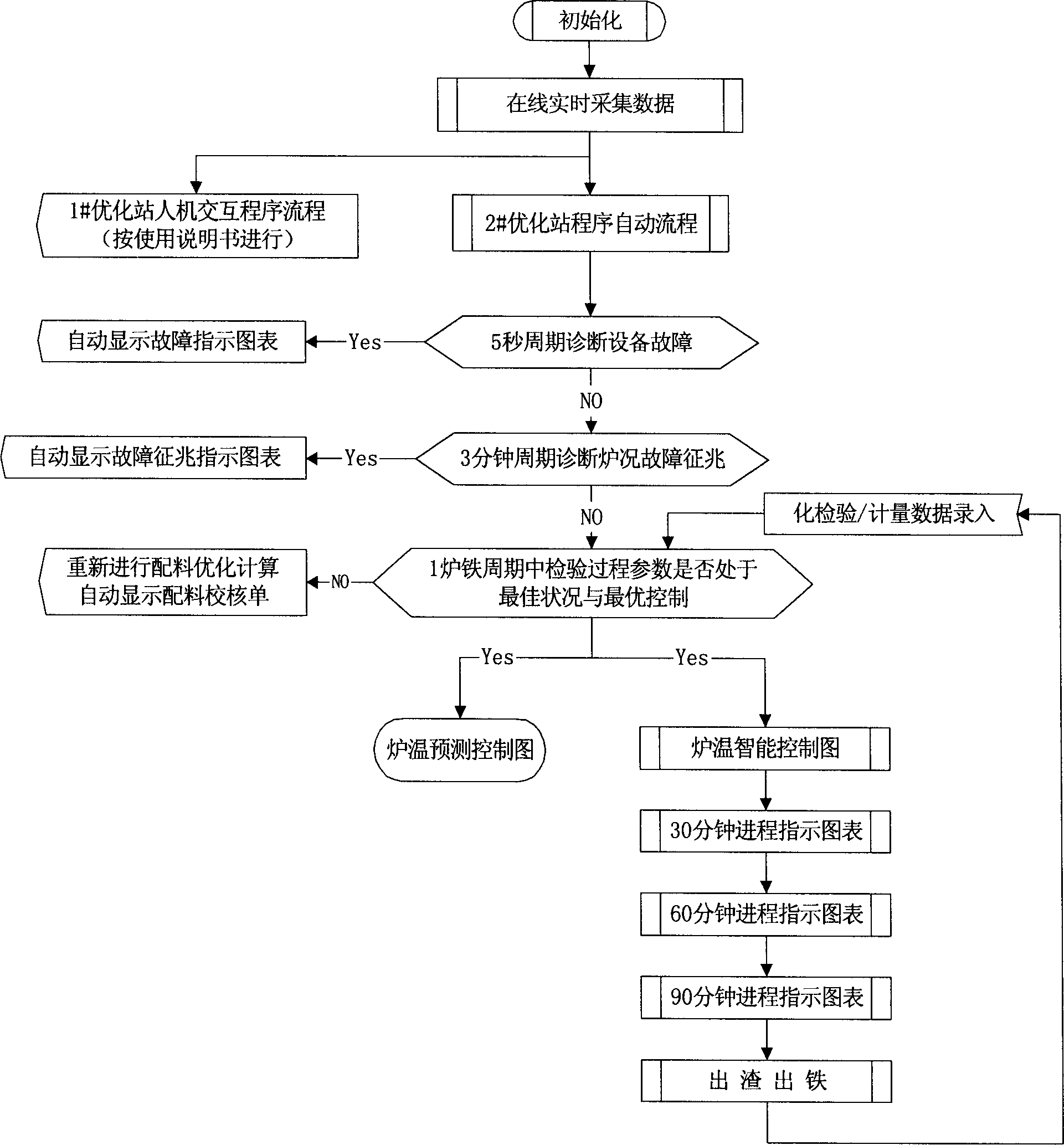

[0038] refer to figure 2 , the intelligent control blast furnace smelting system of the present invention includes sensors for online dynamic collection of blast furnace data, equipped in the main control room of the blast furnace for judging the working state of the blast furnace body, the thermal state of the blast furnace and the forward state of the blast furnace smelting process No. 1 operating station (monitoring Weighing system under the trough), No. 2 operation station (monitoring winch system) and No. 3 operation station (monitoring the parameters of the blast furnace body), and a No. 1 optimization station and a server are innovatively set up in the main control room of the blast furnace (database server 1) No. 2 optimization station two microcomputers, and three operation stations form the main control room local area network, constitute the hardware platform for the foreman's intelligent operation; at the same time, a local area network server 5 is set up in the ir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com