Chip support for protecting chip from breakdown by static electricity

A technology for wafer holders and wafers, which is applied in the direction of grinding workpiece holders, supports, circuits, etc., and can solve problems such as leakage of electrostatic charges, failure to protect wafers from electrostatic breakdown, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

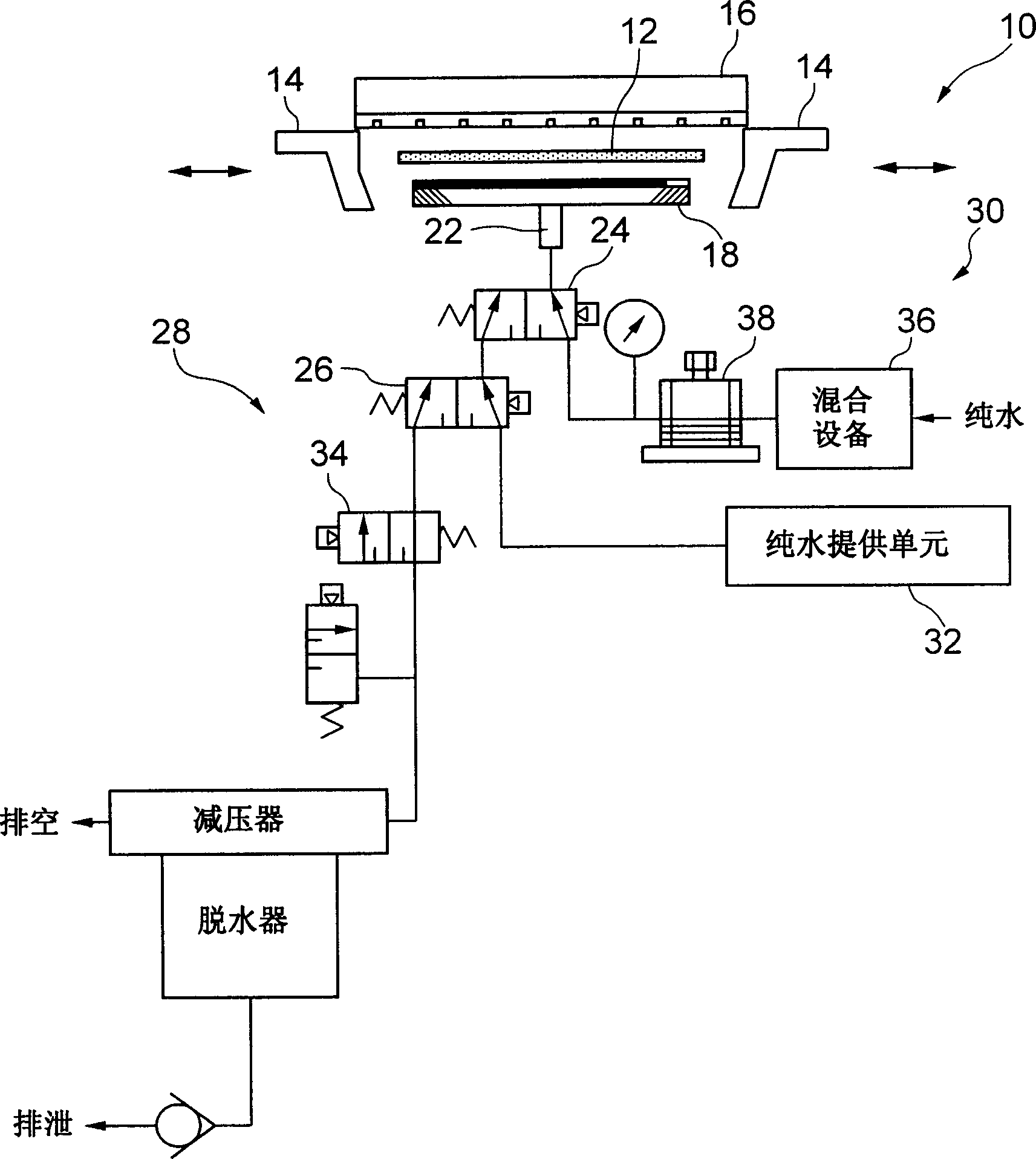

[0014] In one embodiment of the invention, the wafer holder is used in a chemical mechanical polishing (CMP) apparatus. The CMP apparatus receives a wafer from a production line through a wafer holder, places the wafer in a grinding head while centering the wafer thereon, and thereby polishes the wafer.

[0015] For the same mount on it, the wafer holder is used to pick up the wafer, and release the wafer from the picked up state by using a liquid.

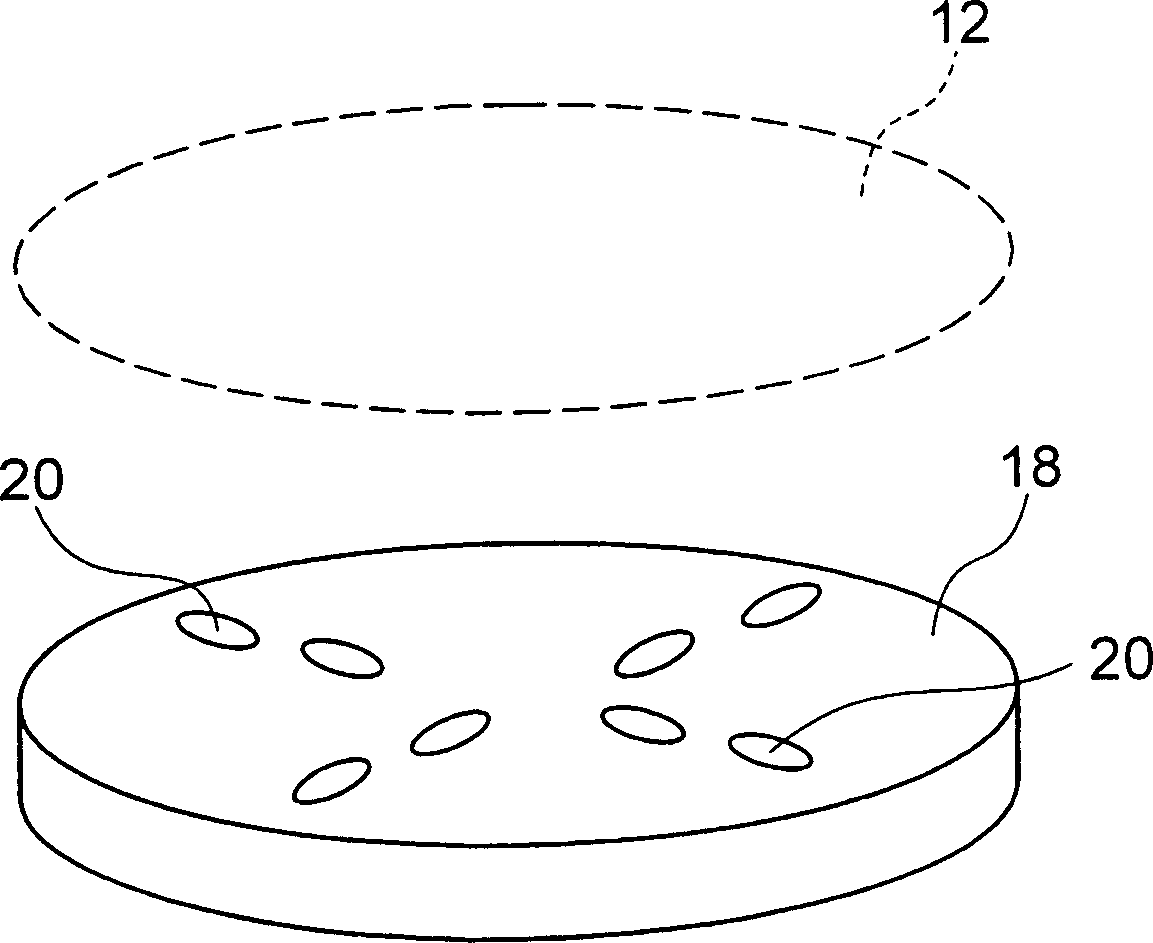

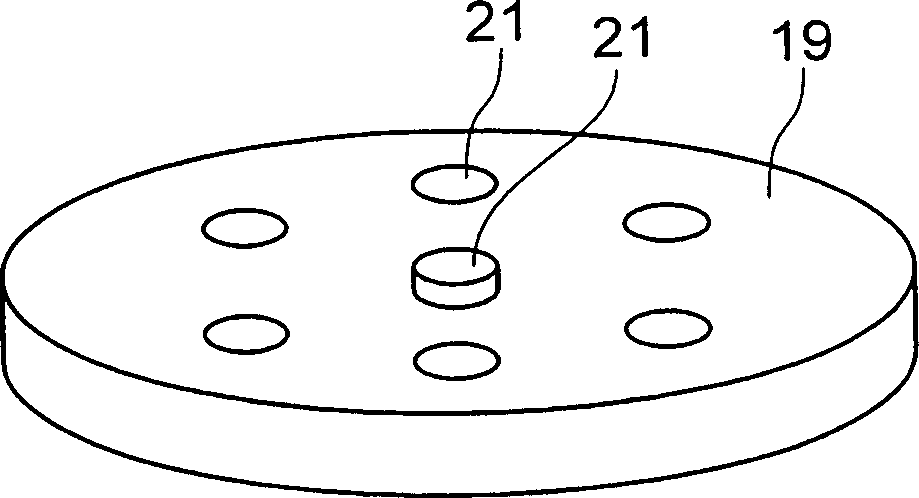

[0016] In one embodiment of the invention, when a processing robot places the wafer on the mounting plate of the wafer holder, the fluid evacuation member is selectively in communication and operable with the fluid hole to draw air surrounding the wafer holder through the fluid hole, And the wafer is sucked by evacuating air from the fluid evacuation part through the fluid hole.

[0017] The wafer holder then releases the wafer from suction for wafer centering with the CMP equipment. At this stage, the liquid supply unit optiona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com