Sampling container for fused metal thermal analysis

A technology for sampling container and molten metal, which is applied in the direction of material thermal analysis, sampling, sampling device, etc., can solve the problems of large gradient of cooling curve, large outer size of container, failure to sample molten metal in a predetermined amount, etc. The effect of simplifying the internal structure and reducing the driving force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Here, preferred embodiments of the present invention will be described with reference to the accompanying drawings.

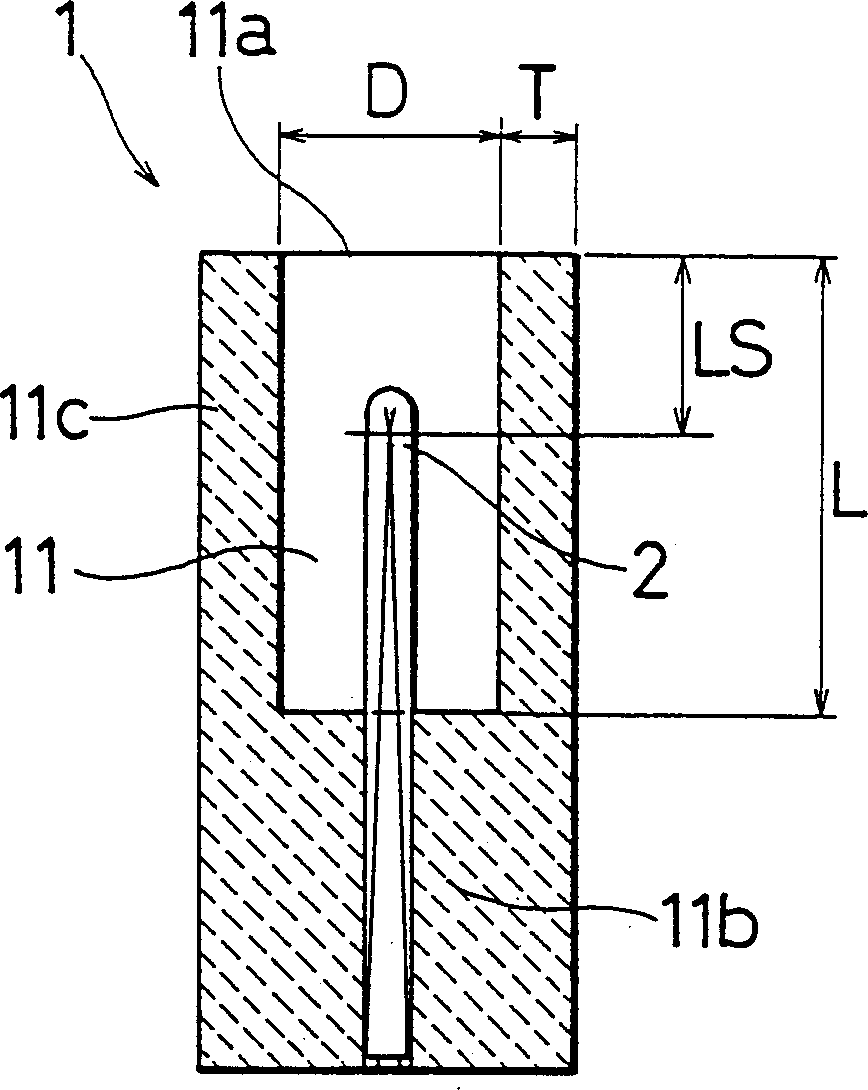

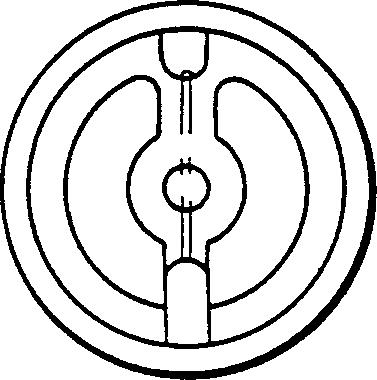

[0037] Fig. 1 is an explanatory view of an embodiment of the present invention when applied to a cup-type sampling container, Fig. 1(A) is a longitudinal sectional view, and Fig. 1(B) is a bottom view.

[0038] The sampling container 1 is made of baked refractory material, such as ceramics. The sampling container 1 has a cup shape as a whole, and its upper end has an opening 11a for pouring molten metal. A temperature sensor 2, such as a thermocouple made of chromel-alnickel wire, is fixed in such a position that the temperature sensor 2 can be inserted into the sampling chamber 11 through the bottom wall 11b of the chamber.

[0039] In the present example, the diameter D of the sampling chamber is 20 mm, and the depth L of the chamber is 41 mm. The temperature sensor 2 is located within the sampling chamber 11 at a distance LS of 16 mm from the upper ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com