Cathod ray tube device

A cathode ray tube and coil technology, applied in the direction of cathode ray tube/electron beam tube, electrode device and related components, discharge tube, etc., can solve the problem of increasing current loss, rising manufacturing cost, deflection coil, and cathode ray tube design burden problems such as increase, to achieve the effects of high manufacturing yield, reduced discreteness, and easy adjustment of dynamic convergence misalignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

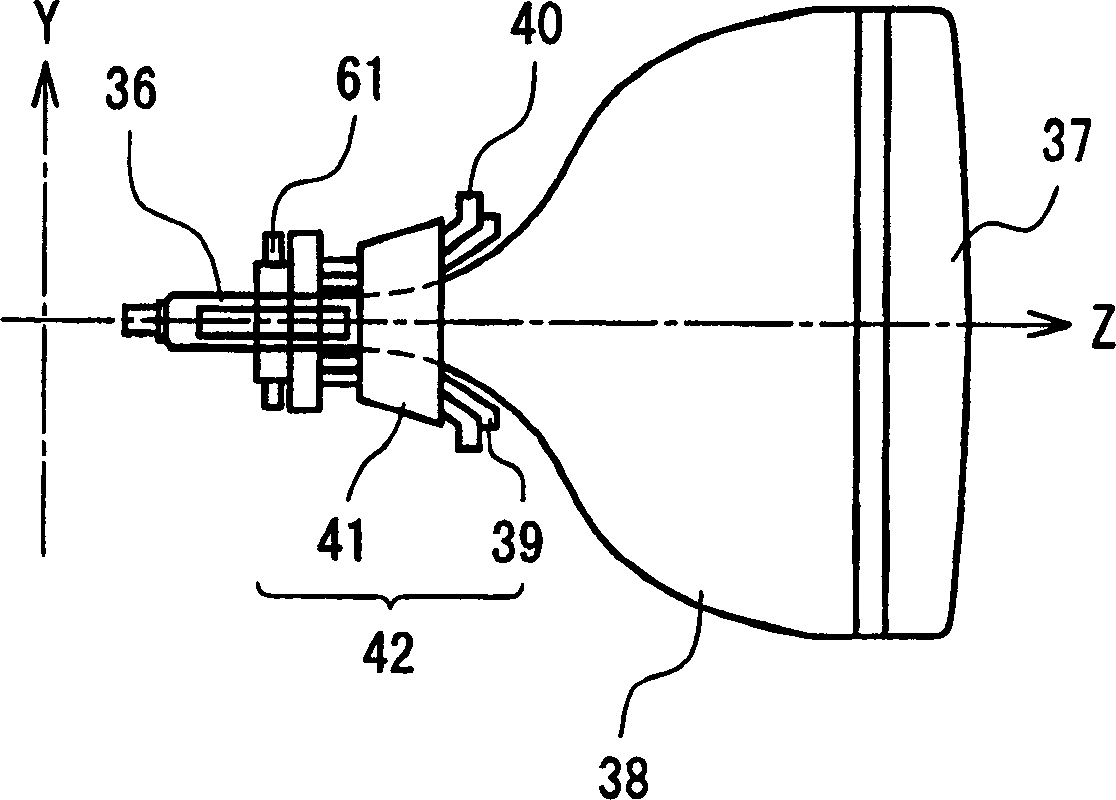

[0037] Hereinafter, a cathode ray tube device according to an embodiment of the present invention will be described with reference to the drawings. figure 1 It is a plan view of the cathode ray tube device according to the embodiment of the present invention.

[0038] figure 1 Among them, the cathode ray tube body 36 is composed of a glass panel 37 and a glass funnel 38 connected to the rear of the glass panel 37 . On the rear portion of the cathode ray tube body 36, an electron gun is provided. Moreover, on the rear portion outer periphery of the cathode ray tube body 36, a horizontal deflection coil 39 wound into a saddle shape, a saddle-type vertical deflection coil 40 disposed on the outside of the horizontal deflection coil 39, and a vertical deflection coil 40 disposed on the outside of the vertical deflection coil 40 are installed. The ferrite core 41 on the outer side constitutes the deflection yoke 42 .

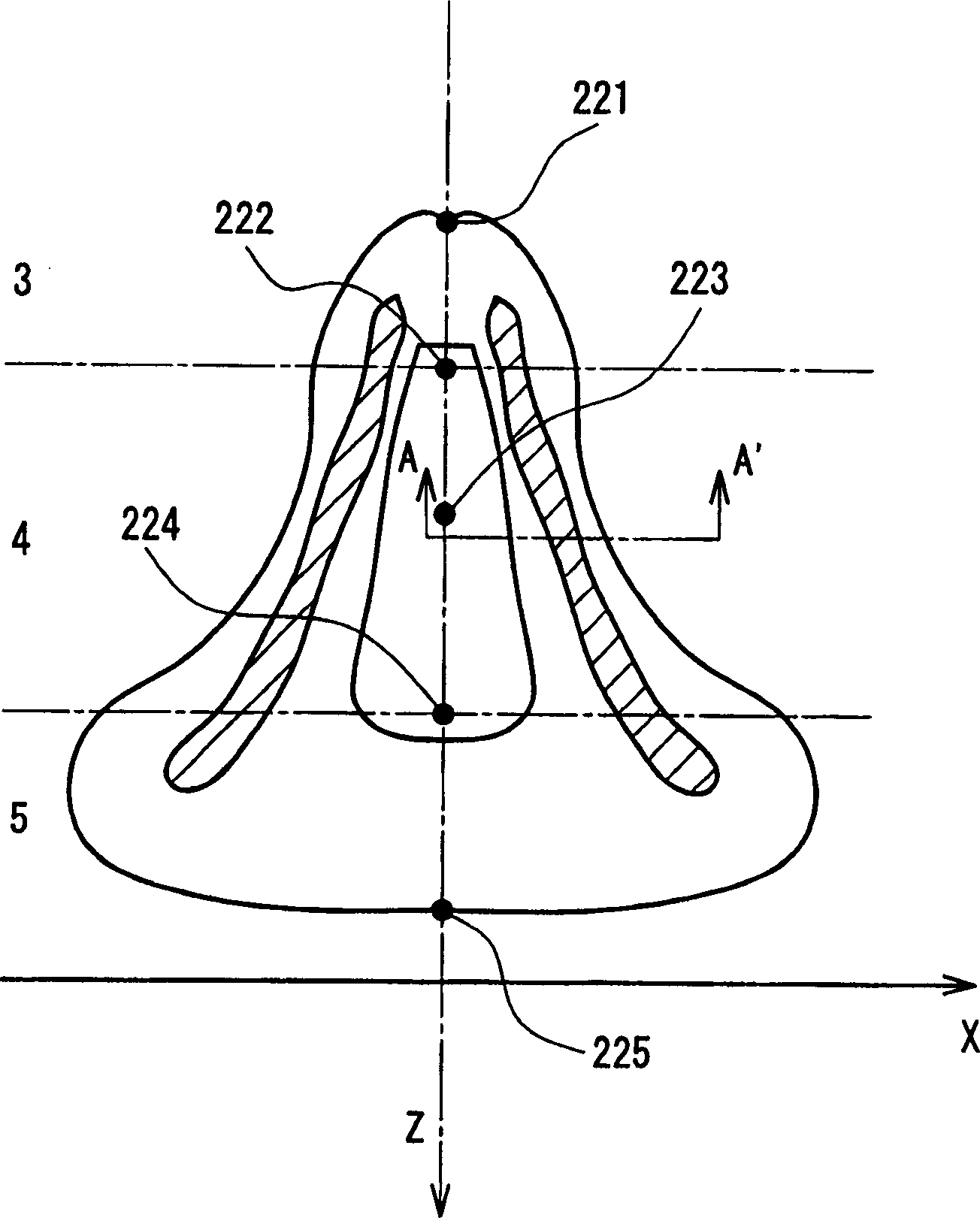

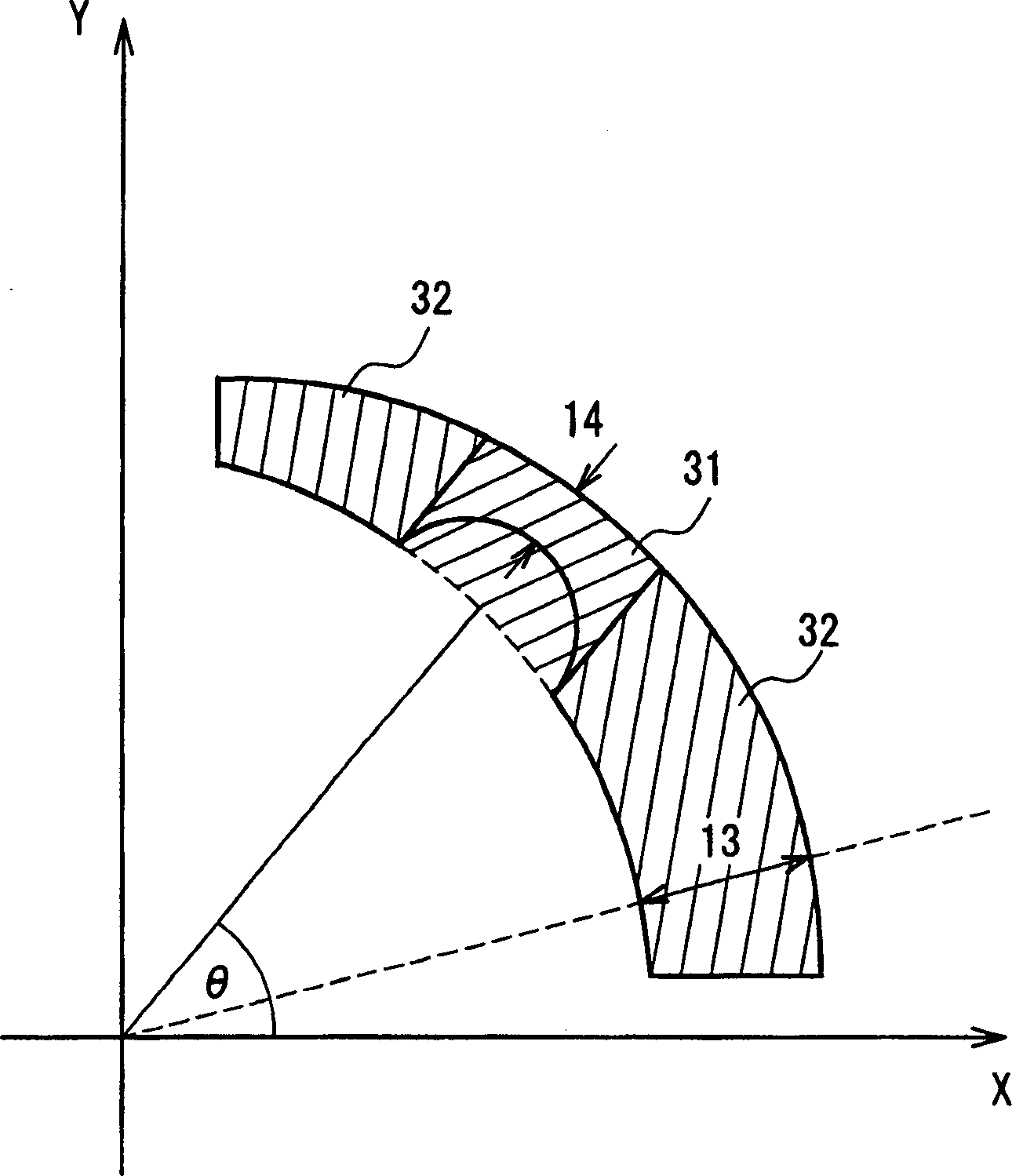

[0039] figure 2 The drawing of the horizontal deflection c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com