Fluidized bed type dryer and drying method

A technology of drying device and drying method, which is applied in the direction of drying gas arrangement, hearth furnace, drying solid materials, etc., can solve the problems of impeding flowing gas ejection, scattering, and insufficient dispersion of processed materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

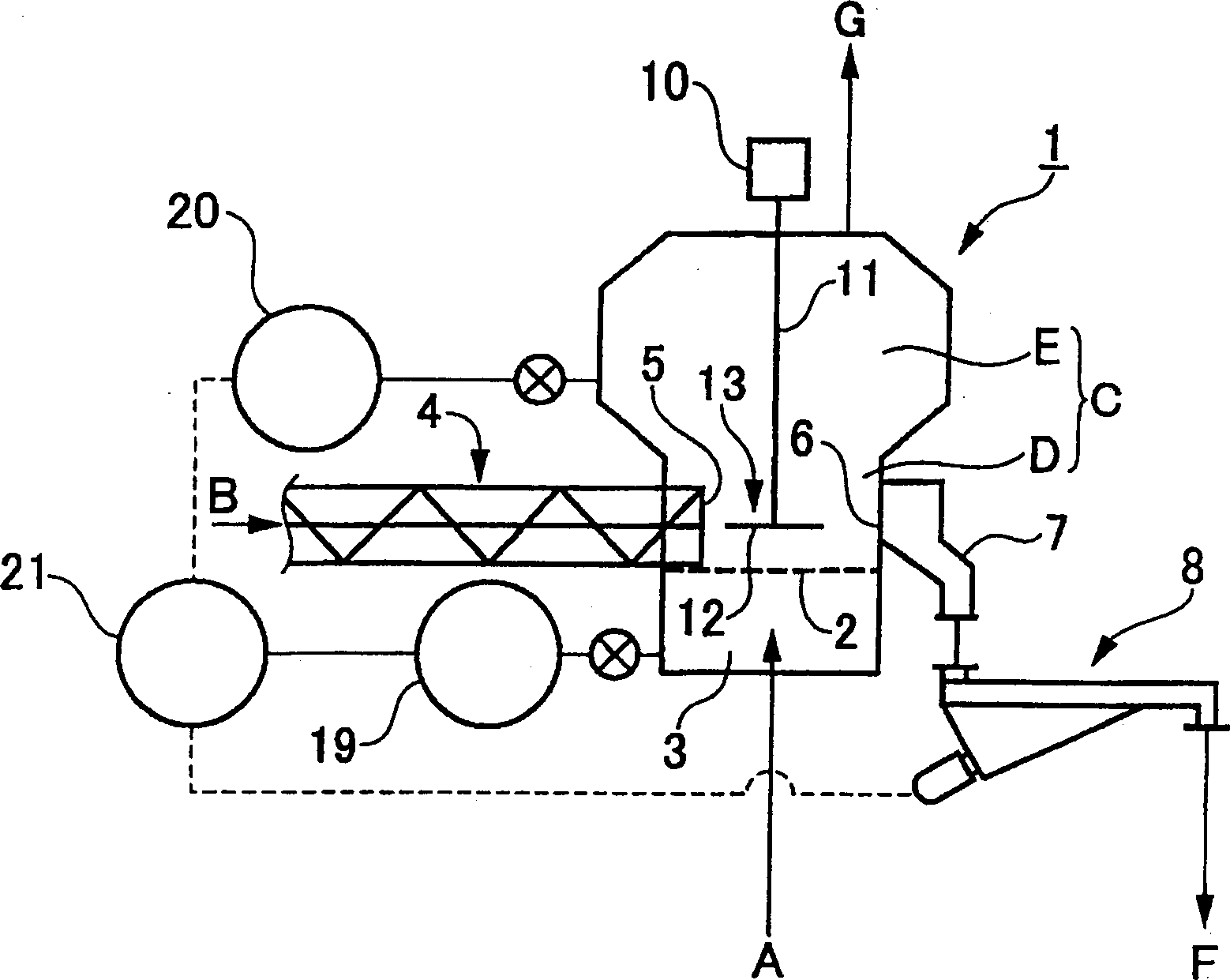

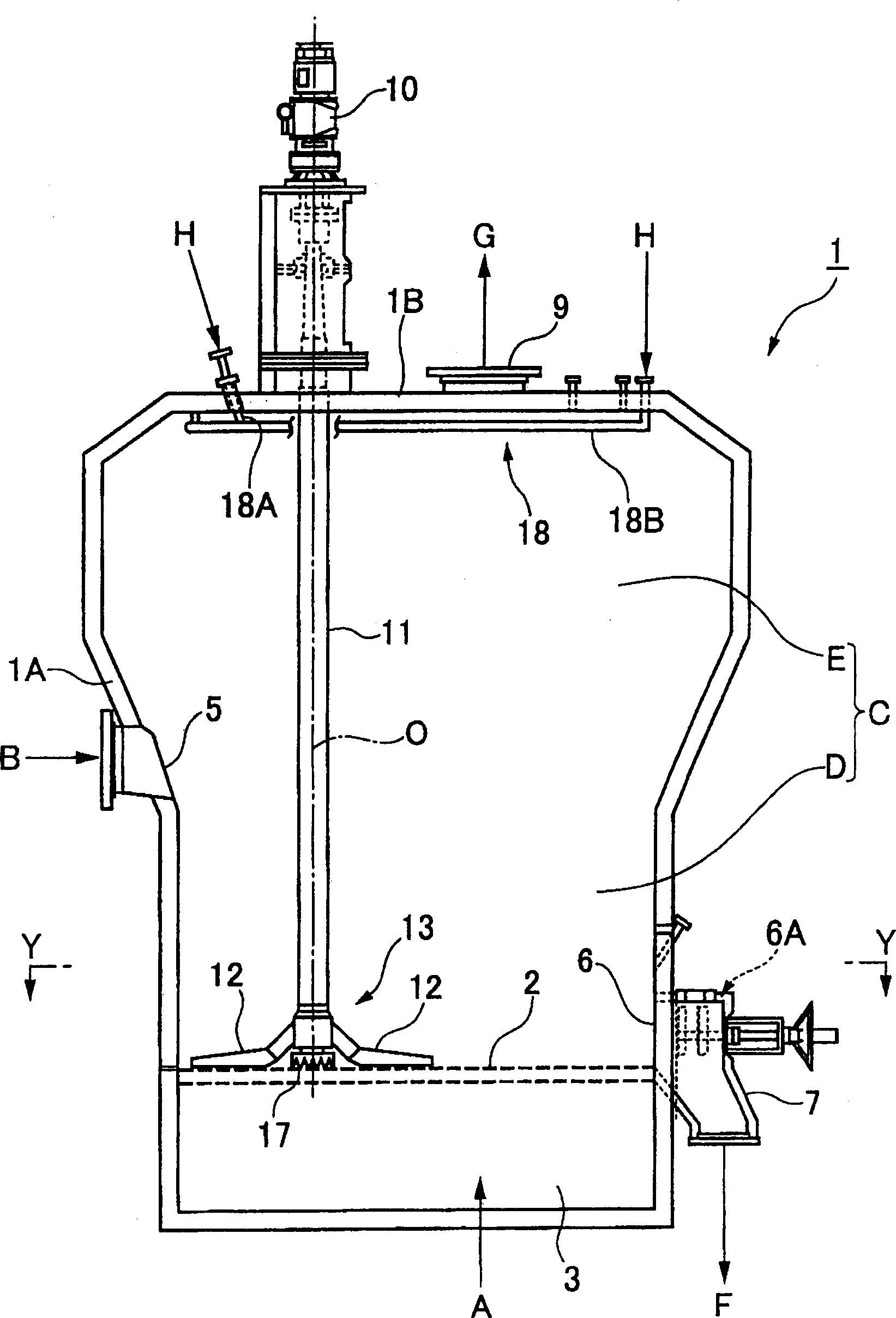

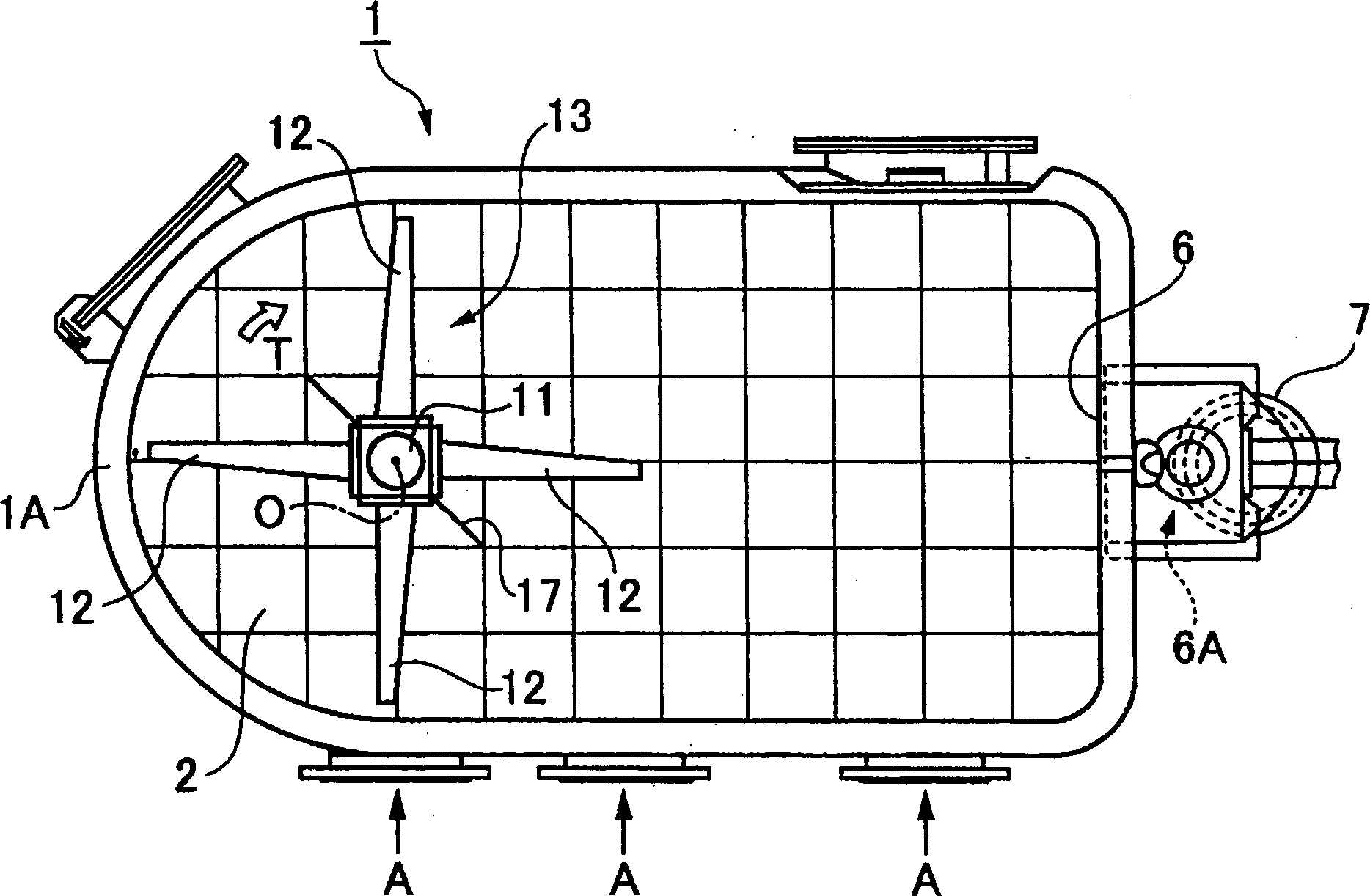

[0018] Figure 1 to Figure 6 is a schematic diagram of an embodiment of the fluidized bed drying apparatus of the present invention. in figure 1 It is a schematic diagram of the fluidized bed drying device of the present embodiment and its peripheral devices, such as figure 1 As shown, in the device main body 1 of the fluidized bed drying device, a dispersing plate 2 is horizontally arranged at the lower part thereof, and a pressurized chamber 3 for supplying flowing gas (high temperature air) A is formed on the lower side of the dispersing plate 2 , and on the side wall 1A of the device main body 1 on the upper side of the dispersion plate 2, a feed port 5 connected to a treatment material B supply mechanism 4 such as a screw conveyor is provided, and the feed port 5 is supplied to the device main body 1. The processed material B inside is dispersed and flowed by the above-mentioned flowing gas A injected from the pressurized chamber 3 through the distribution plate 2, ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com