Method for producing acetamiprid

A production method, acetamiprid technology, applied in the field of acetamiprid production, can solve problems such as insufficient reaction, unsatisfactory reaction selectivity and yield of chemical synthesis, uneven mixing of materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with embodiment:

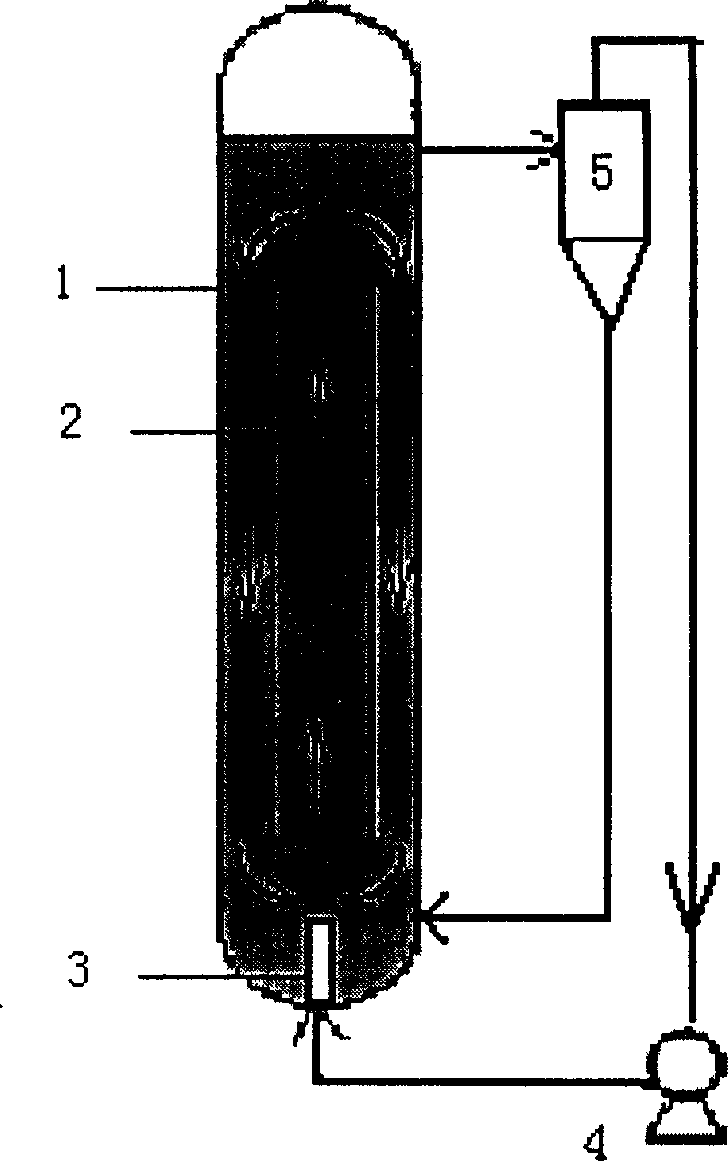

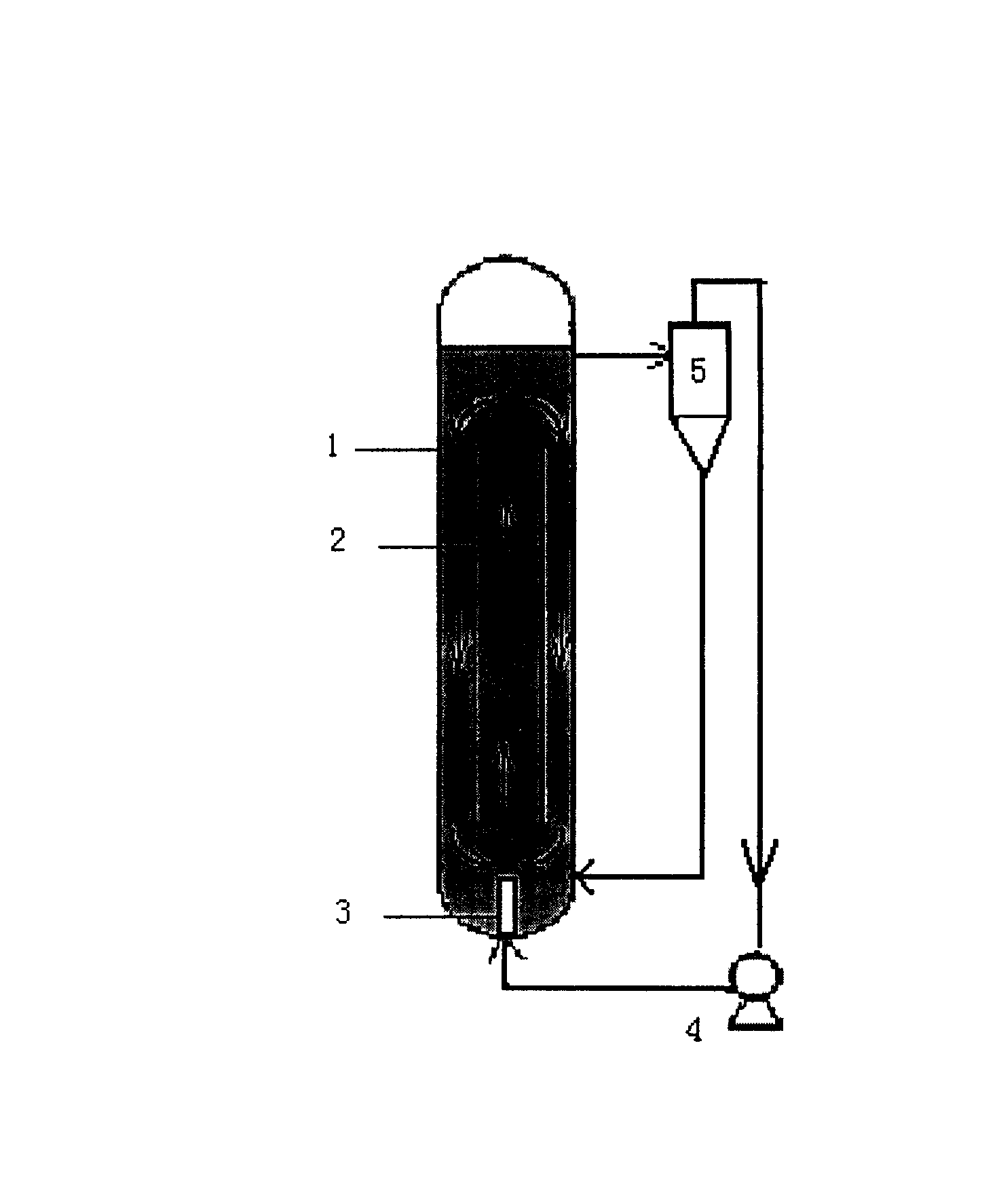

[0013] 1. Add N-cyano-N-methylacetamidine, anhydrous potassium carbonate, benzyltriethylammonium chloride, and dimethylformamide in a jet loop reactor with a molar ratio of 1:1.5:0.02:5 , turn on the jet pump 4 of the jet loop reactor 1, and under the impetus of the jet pump 4, the material and the solvent circulate in the jet loop reactor 1, flow upward in the guide tube 2, and flow between the guide tube 2 and the jet loop reactor. The annulus of reactor 1 flows downward, and the mixture of overflow material and solvent passes through the cyclone separator 5 to complete solid-liquid separation, and the solid material returns to the jet loop reactor 1 from the bottom of the cyclone separator 5, and the liquid material is circulated externally. Under the impetus of the jet pump 4, it is sprayed into the jet loop reactor 1 again through the nozzle 3, so that the material and the solve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com