Red luminescent powder mixed with europium and its method

A red phosphor, alkaline earth technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problem of high price of rare earth phosphors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

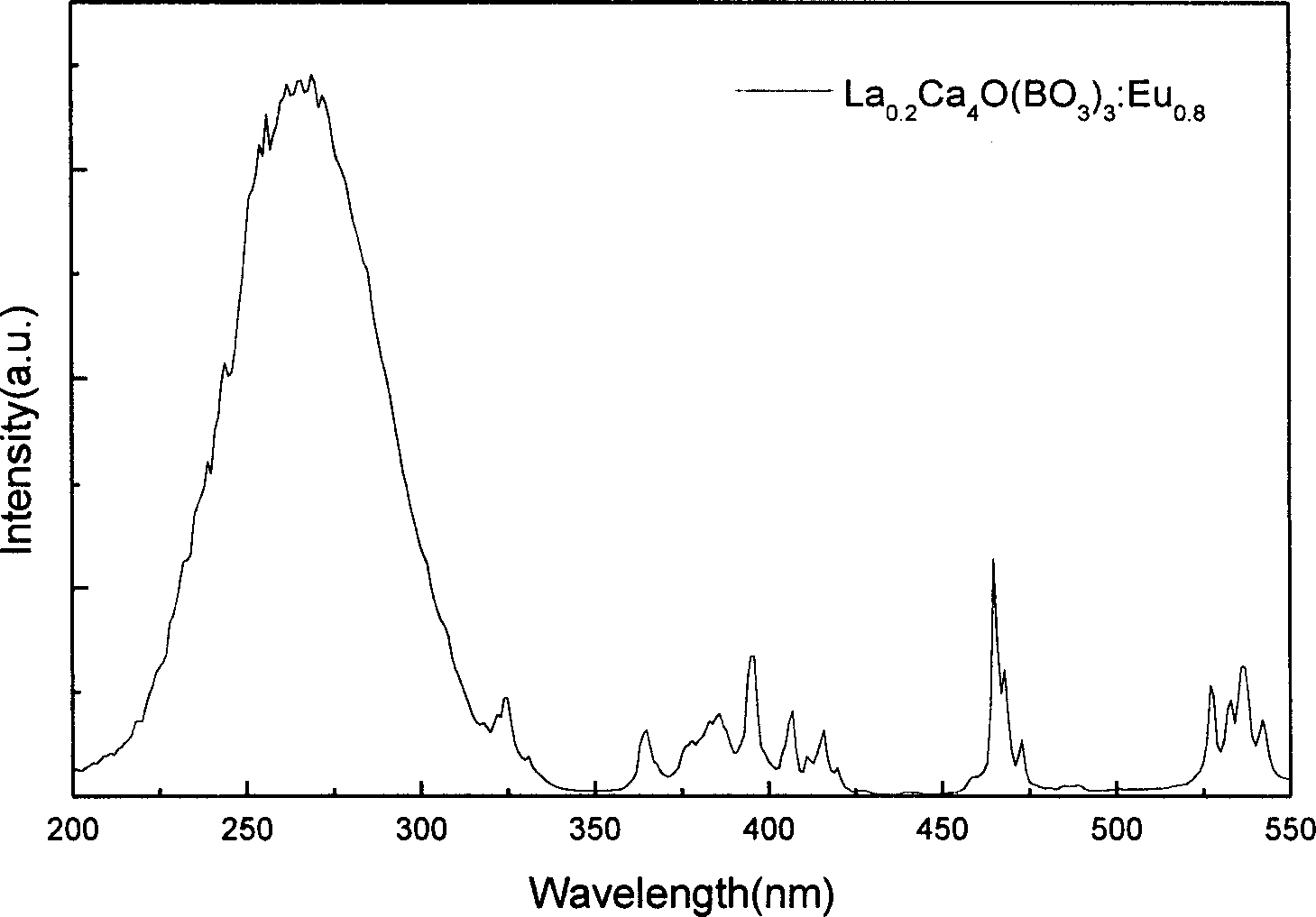

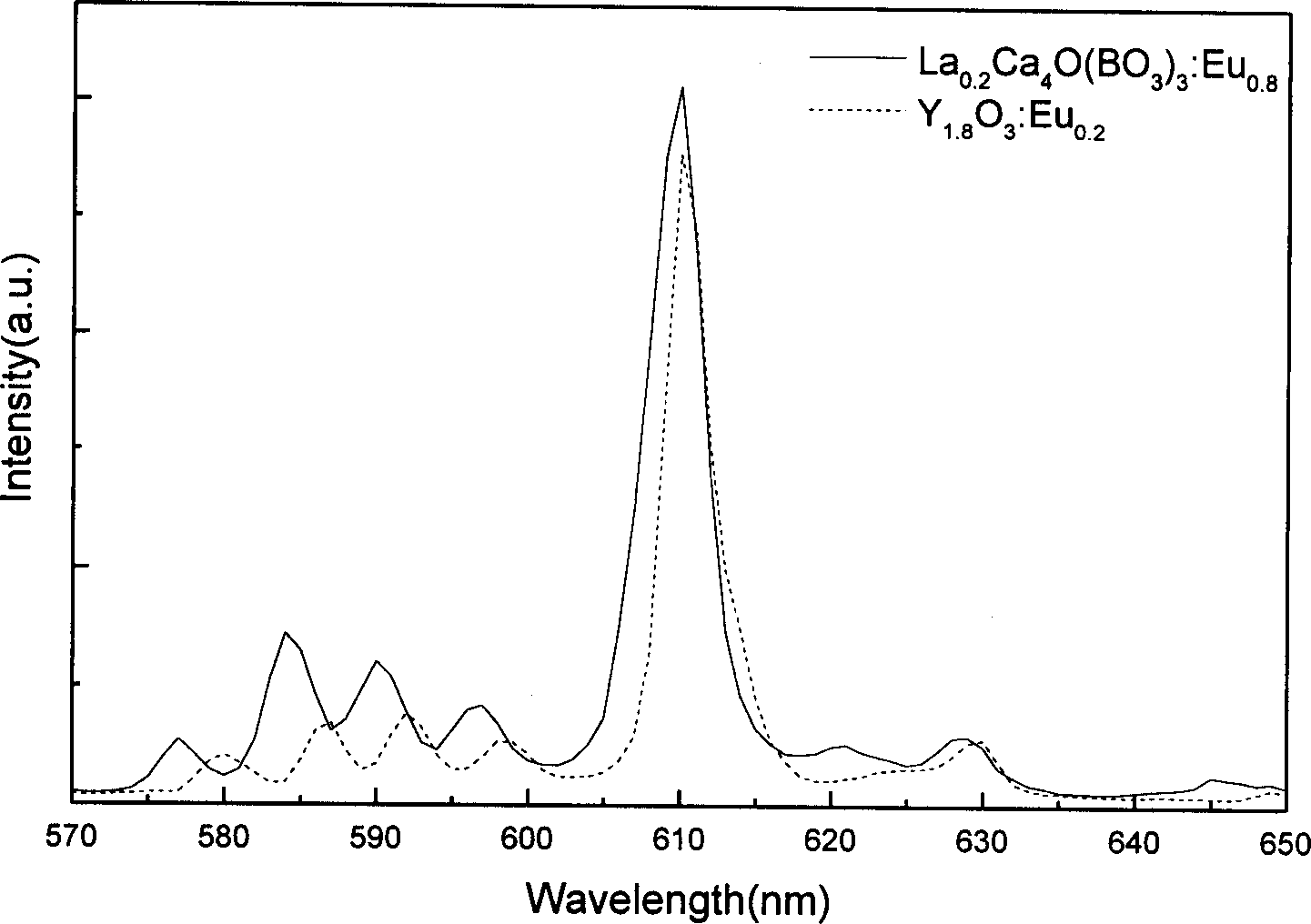

[0012] The raw material is La 2 o 3 (99.99%), CaCO 3 (analytical pure), H 3 BO 3 (analytical pure), Eu 2 o 3 (99.99%). The molar ratio between them is correspondingly 0.1:4:3.15:0.4. Fully grind the raw materials, pre-fire at 900°C for 10 hours, cool to room temperature, grind again, put them into a corundum crucible, and sinter at 1200°C for 10 hours. Take out and grind to get the sample. The obtained sample was a pure white powder, due to H 3 BO 3 There is volatilization during the reaction, and the product La 0.2 Ca 4 O(BO 3 ) 3 :Eu 0.8 . Its emission spectrum when excited at 254nm is as attached Figure 1 Show. Its main peak is at 610nm, and Y 2 o 3 :Eu 3+ resemblance. Integrate the two curves in the 570-650nm range respectively, and then divide, the sample of the present embodiment and Y 1.8 o 3 :Eu 3+ 0.2 The ratio of the integrated areas of the emission curves is 1.439.

Embodiment 2

[0014] La 2 o 3 , CaCO 3 、H 3 BO 3 、Eu 2 o 3 The molar ratio between them is 0.1:4:3.15:0.4 accordingly. Grind the raw materials thoroughly and sinter at 900°C for 10 hours. Take out and grind to get the sample. The obtained sample was a pure white powder, due to H 3 BO 3 There is volatilization during the reaction, and the product La 0.2 Ca 4 O(BO 3 ) 3 :Eu 0.8 . When excited with 254nm, its main peak is 610nm, and Y 2 o 3 :Eu 3+ resemblance. The sample of this embodiment 2 and Y 1.8 o 3 :Eu 3+ 0.2 The ratio of the integral area in the range of 570-650nm for the emission curve excited at 254nm is about 0.60.

Embodiment 3

[0016] Y 2 o 3 , CaCO 3 、H 3 BO 3 、Eu 2 o 3 The molar ratio between them is 0.1:4:3.15:0.4 accordingly. Grind the raw materials thoroughly, pre-fire at 900°C for 7 hours, cool to room temperature, grind thoroughly again, put them into a corundum crucible, and sinter at 1500°C for 1 hour. Take out and grind to get the sample. The obtained sample was a pure white powder, due to H 3 BO 3 There is volatilization during the reaction, the product Y 0.2 Ca 4 O(BO 3 ) 3 :Eu 0.8 . When excited with 254nm, its main peak is 610nm, and Y 2 o 3 :Eu 3+ resemblance. The sample of this embodiment 3 and Y 1.8 o 3 :Eu 3+ 0.2 The ratio of the integral area of the emission curve excited at 254 nm in the range of 570-650 nm is 0.95.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com