Compressor

A compressor and pressure plate technology, applied in the field of fluid compressors, can solve the problems of complex structure, large compressor volume, and large radial size protrusion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

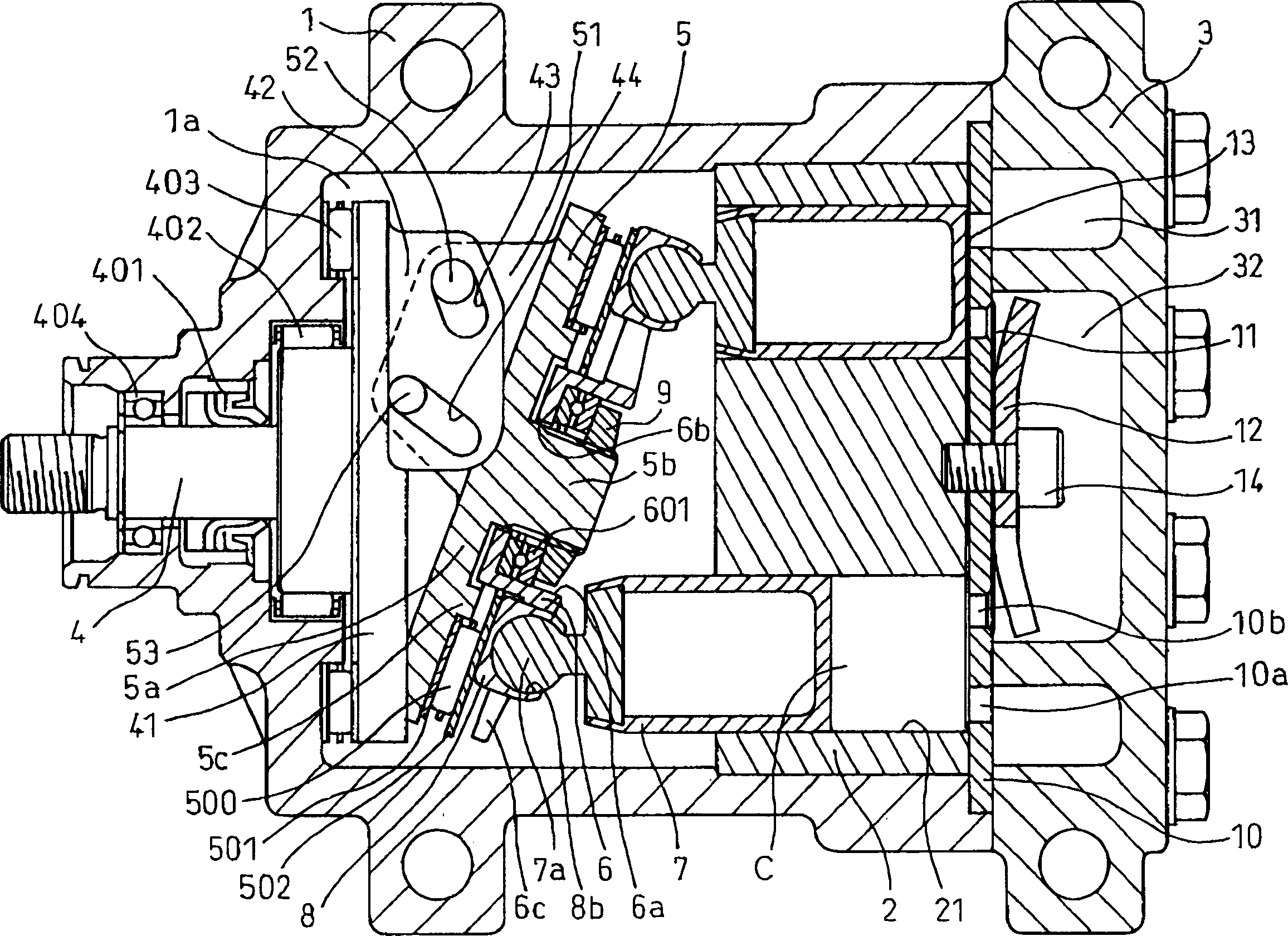

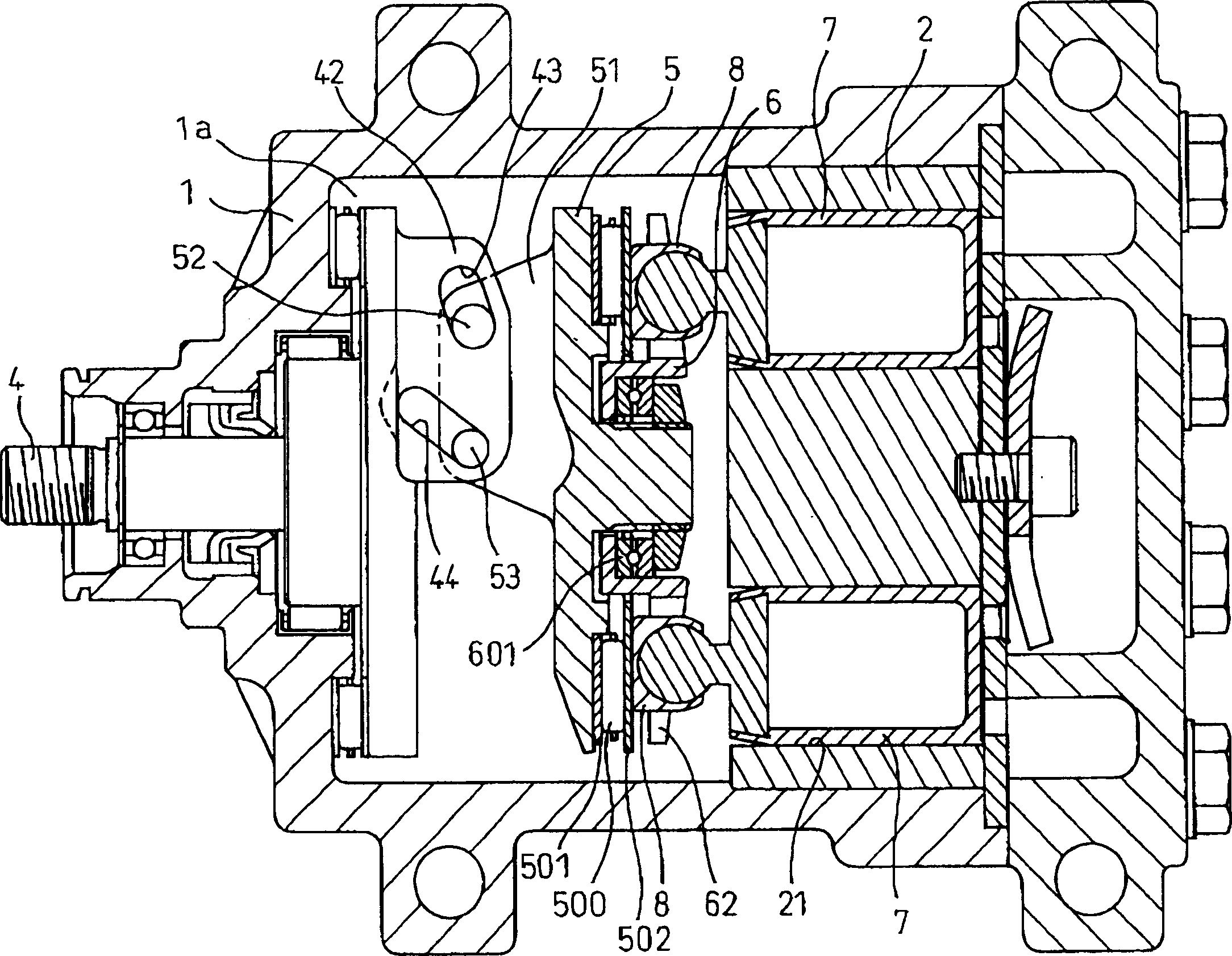

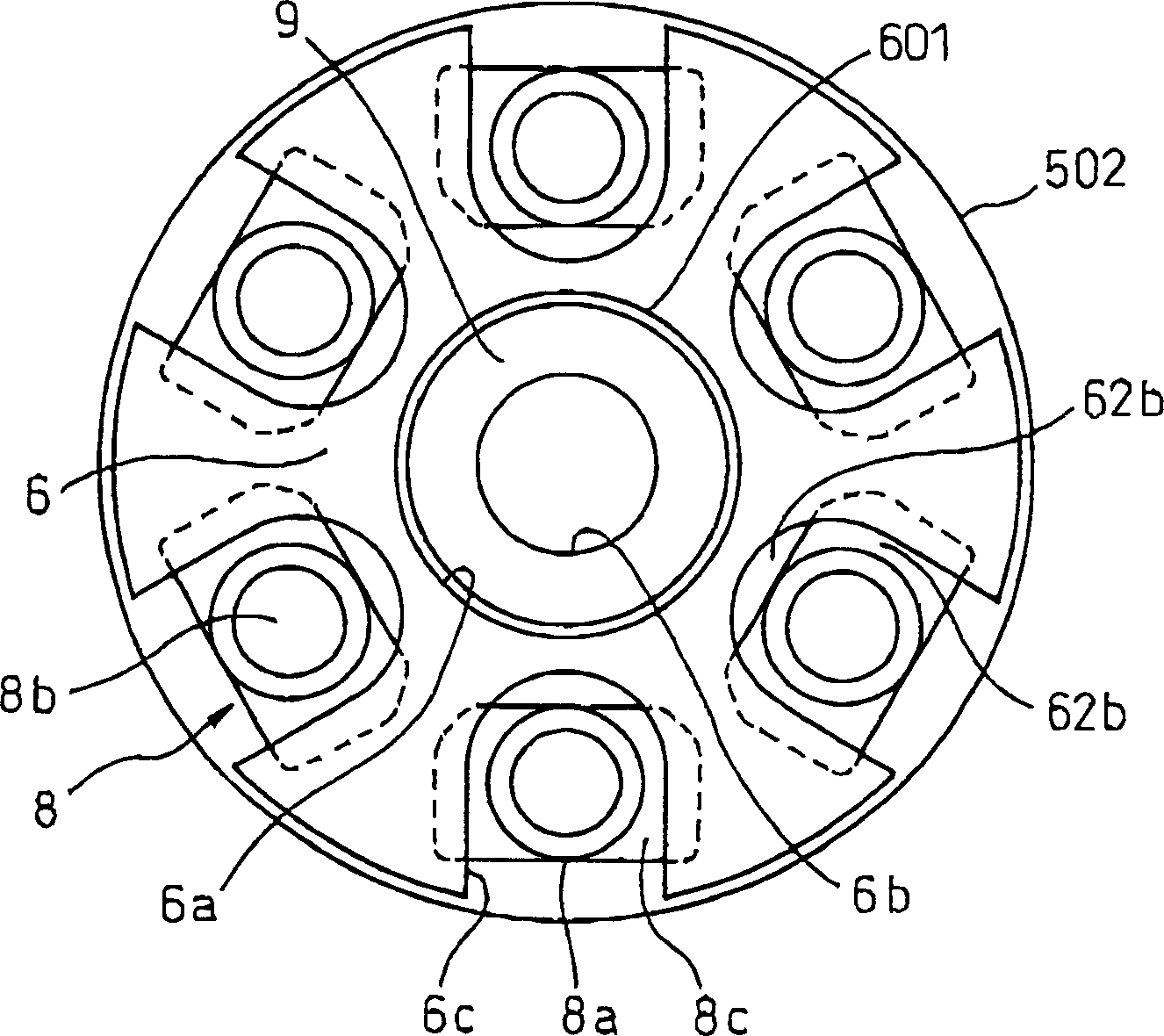

[0100] The specific shape of the tile support plate 6 of embodiment 1, if referring to figure 1 , figure 2 and image 3 It's clear. The shoe support plate 6 has a concave surface 6a at the center, and a shoe support plate thrust bearing 601 can be installed in the concave surface 6a. As described above, the center hole 6b for mounting the hub 5b of the drive disk 5 is formed at the center portion of the concave surface 6a. There are radial U-shaped notches with the same number (for example, 6) as the number of pistons 7 on the edge of the tile holding plate 6 as guide grooves 6c.

[0101] There is a sliding fit in the guide groove 6c image 3 and Figure 4The shoe main body 8a of the friction-resistant shoe 8 having the shape shown is approximately a cylindrical shape with a bottom. The tile support plate 6 and the drive disc 5 can be matched in relative rotation, and the shoe support main body 8a installed in the guide groove 6c of the tile support plate 6 is matched w...

Embodiment 7

[0132] The variable capacity compressor of Embodiment 7 has a torsion coil spring 15 acting in this way, so in Figure 12 The indicated stop of operation or Figure 11 When the discharge capacity shown is zero or the minimum operating state, the force FB2 is generated to increase the inclination angle of the drive disk 5, so the operation stops without the back pressure FH acting in the front frame chamber 1a of the piston 7 state or when the operation starts with little back pressure FH, the driving disk 5 is forced to take a given inclination angle due to the force FB2, and becomes Figure 12 status shown. in addition, Figure 11 As shown, when the discharge capacity is zero or minimum during operation, the internal pressure FH of the front frame chamber 1a is high, and the compression reaction force FP of the working chamber C is small. Even if the force FB2 of the torsion coil spring 15 exists, the drive The inclination angle of the disk 5 becomes zero or minimum. Ther...

Embodiment 14

[0153] The variable capacity compressor of Embodiment 14 has high-speed sliding between the shoe supports 19, 20 and the drive disc 5, so it is not suitable for high-speed, high-load operation, but except for the space between the drive disc 5 and the shoe 8 Except for cooperation, the structure of other parts is the same as that of Embodiment 1, so the drive disc 5 is matched on one side by the drive shaft 4 utilizing a cantilever beam form of a double sliding link mechanism, and the same actual effect of Embodiment 1 can be obtained. Therefore, Embodiment 14 is an example in which the technical idea of the present invention can be applied to a variable capacity compressor using the conventional shoes 19 and 20 .

[0154] In Embodiment 14, as a detailed structure, the arm 51 for driving the disk 5 and the Figure 10 The shown embodiment 7 is the same, and in embodiment 14, it is divided into an upper arm 51a and a lower arm 51b, such as Figure 31 shown, and consists of a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com