Electric actuator and fixing structure of actuator

An actuator and electric technology, applied in the direction of electric components, electromechanical devices, electrical components, etc., can solve the problems of not being able to maintain a fully closed state, bolt hole processing time-consuming, complex and large-scale structures, etc., to achieve excellent safety and man-hours less, the effect of preventing danger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

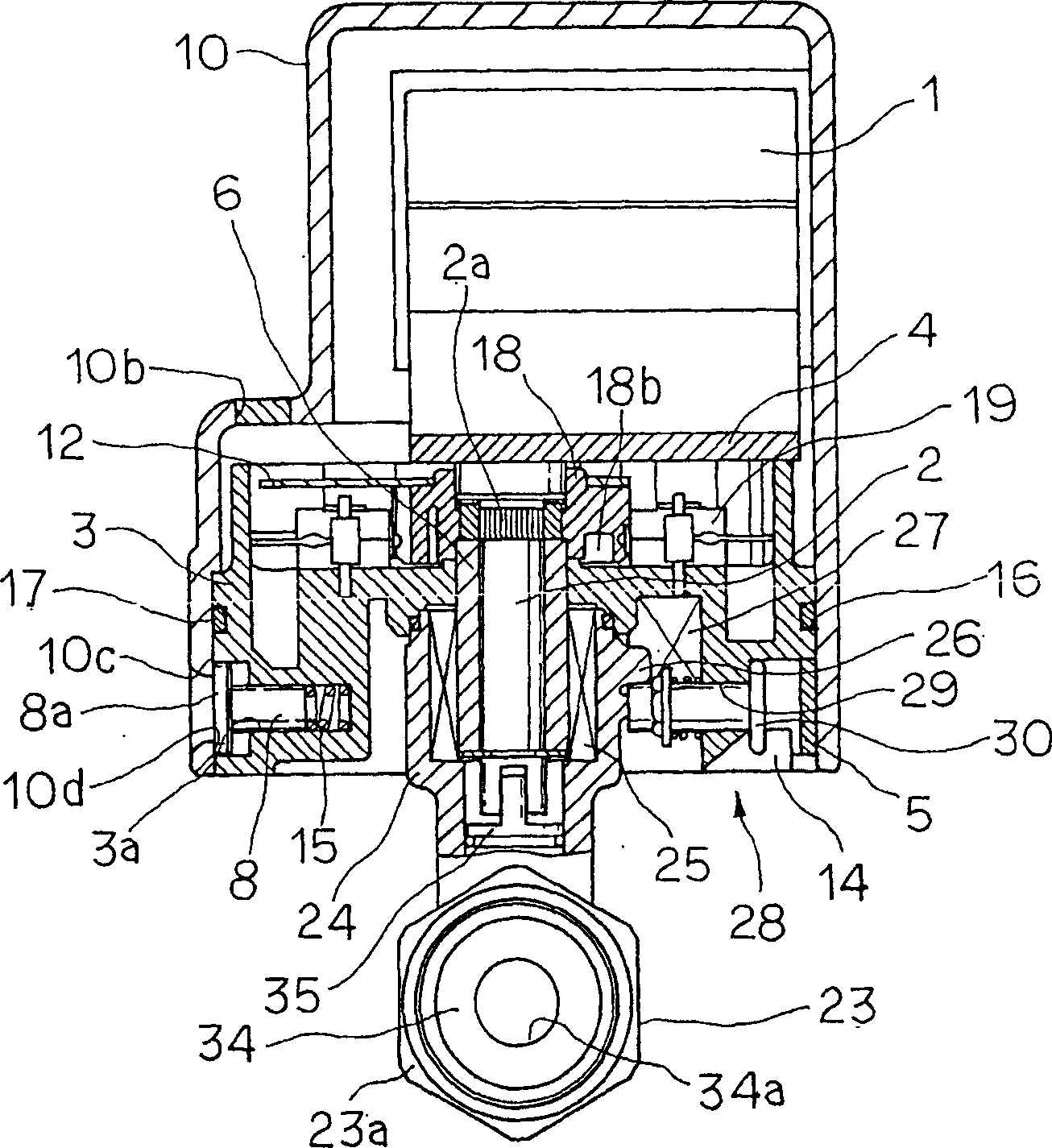

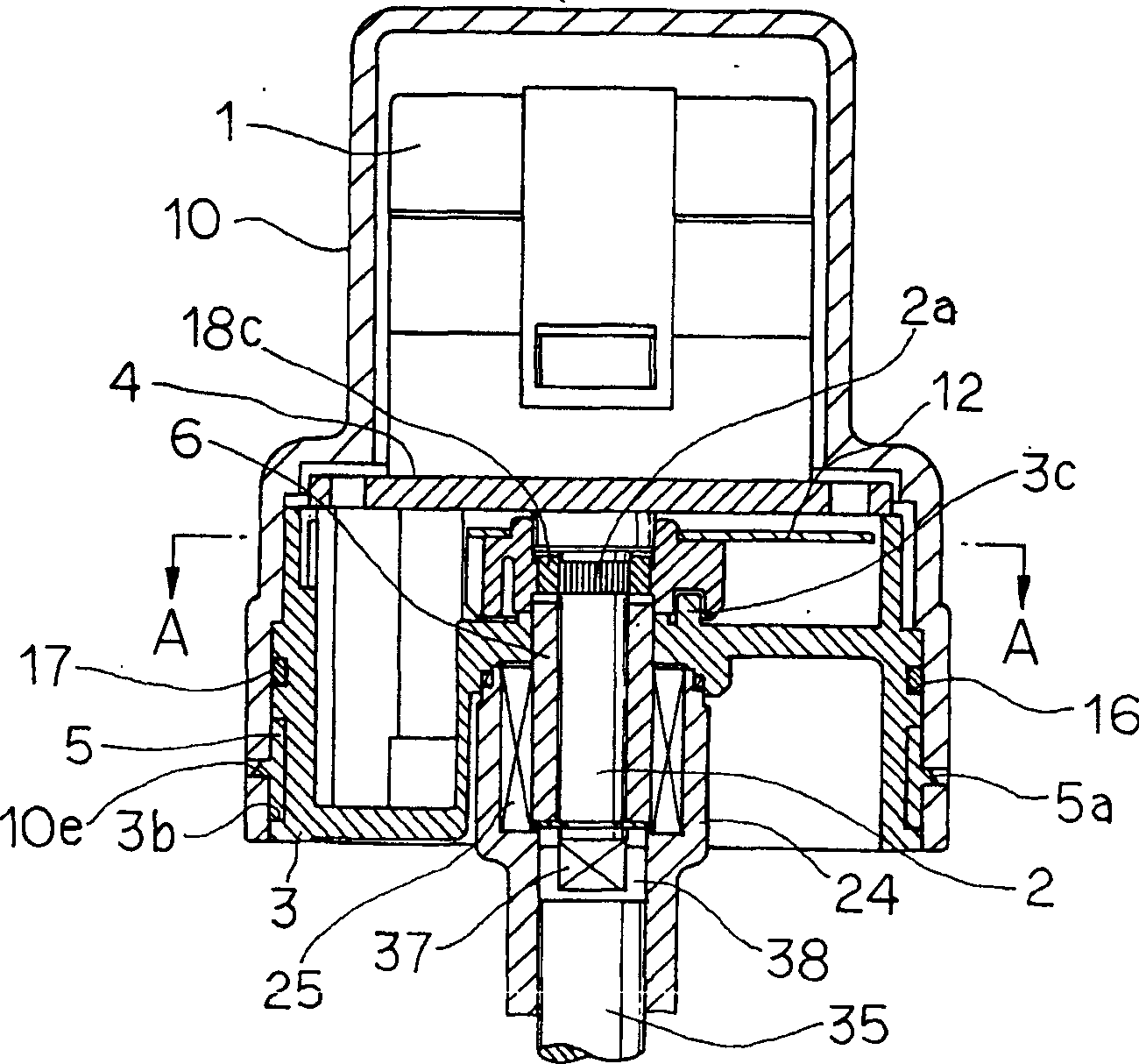

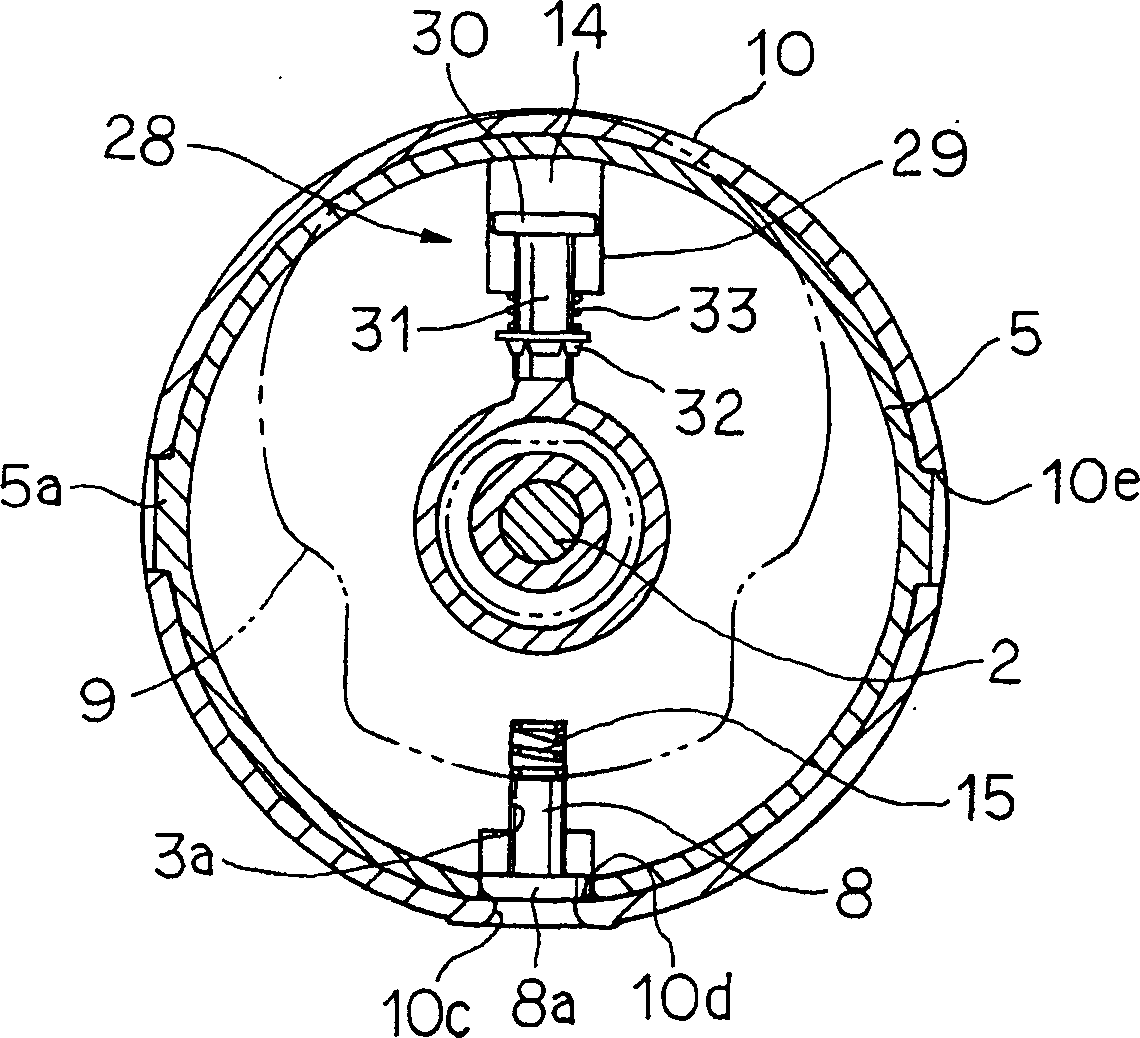

[0072] In order to explain this invention in more detail, it demonstrates using drawing.

[0073] An example of the electric actuator in the present invention applicable to a rotary valve such as a ball valve will be described with reference to the drawings. figure 1 In the present invention, the drive shaft of the motor 1 is pivotably mounted on a disc-shaped base 3 in a freely rotatable manner. The motor 1 uses a geared motor incorporating a reduction gear with a high gear ratio. This geared motor has a self-locking function of the drive shaft 2 when it is not energized. In this case, the drive shaft 2 rotates integrally with the motor 1. .

[0074] Also have, cover body 10 such as Figure 12 As shown, it has a combined curved surface 9 that is easy to hold on the outside, for example, it is in the shape of a manual gas cock, and is a container-shaped cover body integrally molded with synthetic resin. The cap body 10 can be manually operated within a predetermined range o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com