Automatic grinding and drilling machine

A fully automatic, drilling rig technology, used in grinding machines, machine tools suitable for grinding workpiece edges, grinding/polishing equipment, etc. The effect of improving geometric flatness, improving work efficiency and reducing vibration amplitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

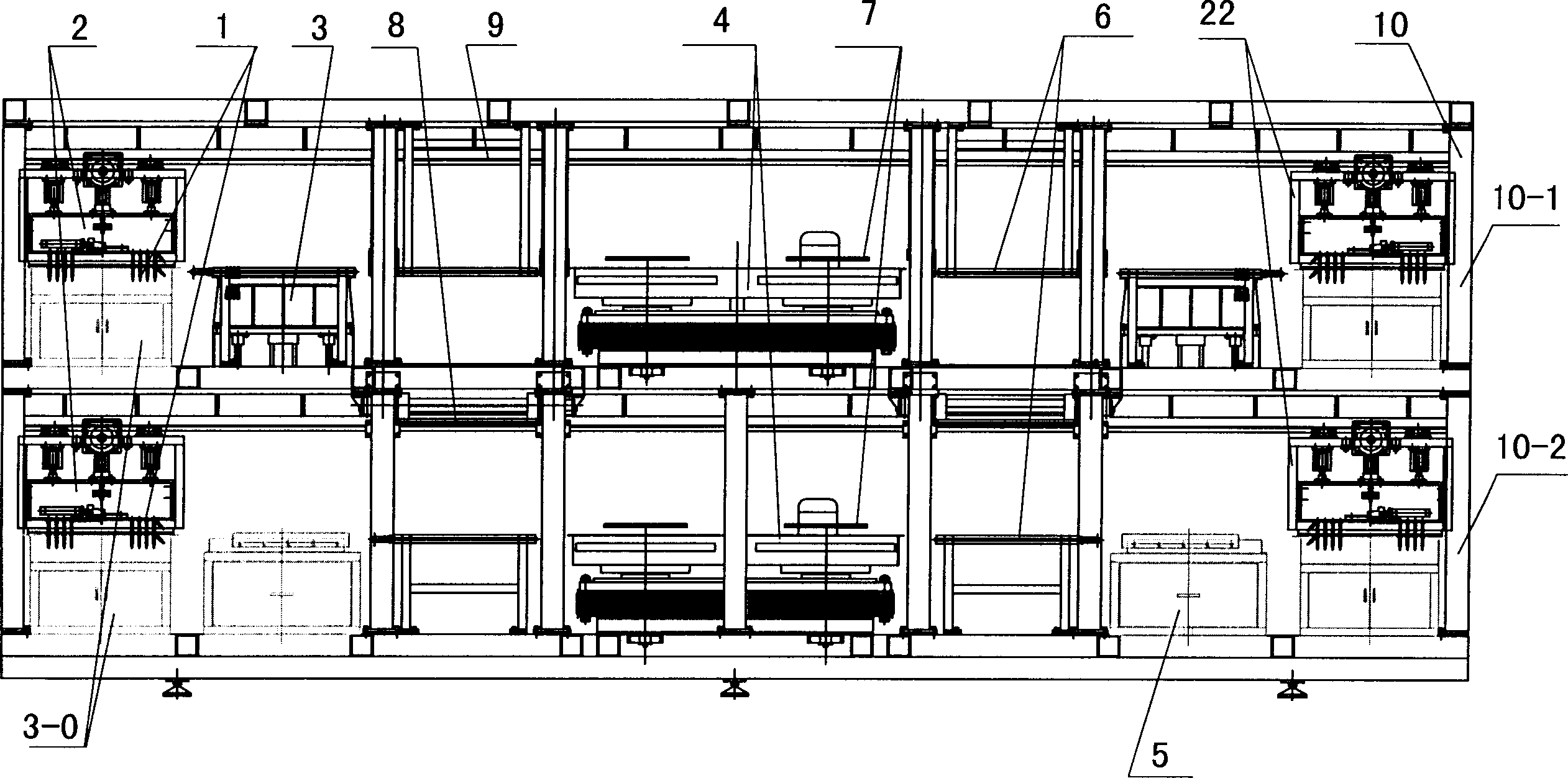

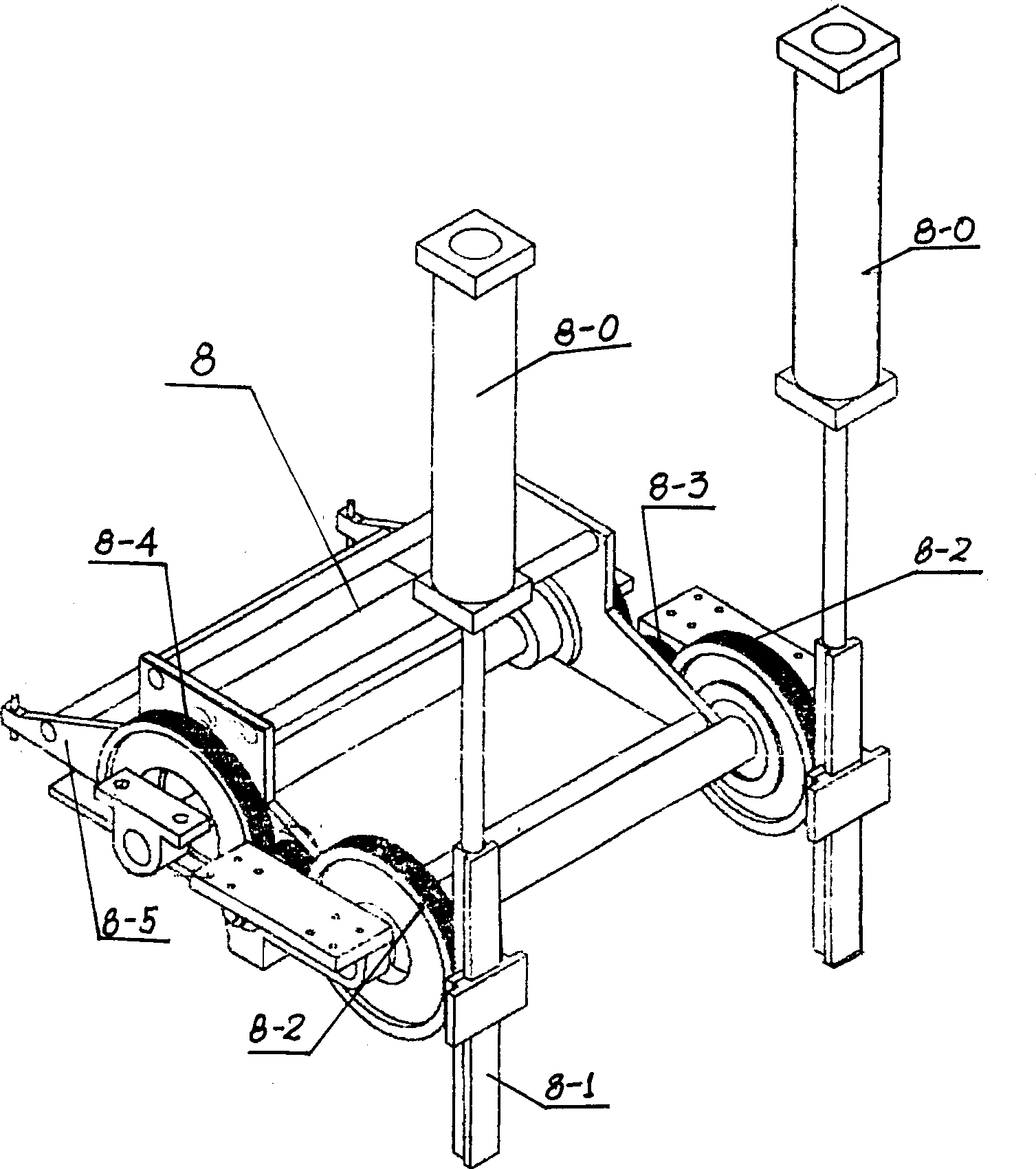

[0026] like figure 1 , 2 As shown, the fully automatic grinding and drilling machine of the present invention includes a sticking rod fixture 1 for fixing the ball blank, a fixture indexing mechanism 2 and a fixture frame 22, a powder holding component 3-0, a feeding device 3, a grinding / polishing wheel 4, a blanking The device 5, the heating mechanism 6, the water supply mechanism 7 and other components are characterized in that: the fully automatic grinding and drilling machine is also equipped with a fixture turning mechanism 8 and a fixture rack conveying mechanism 9;

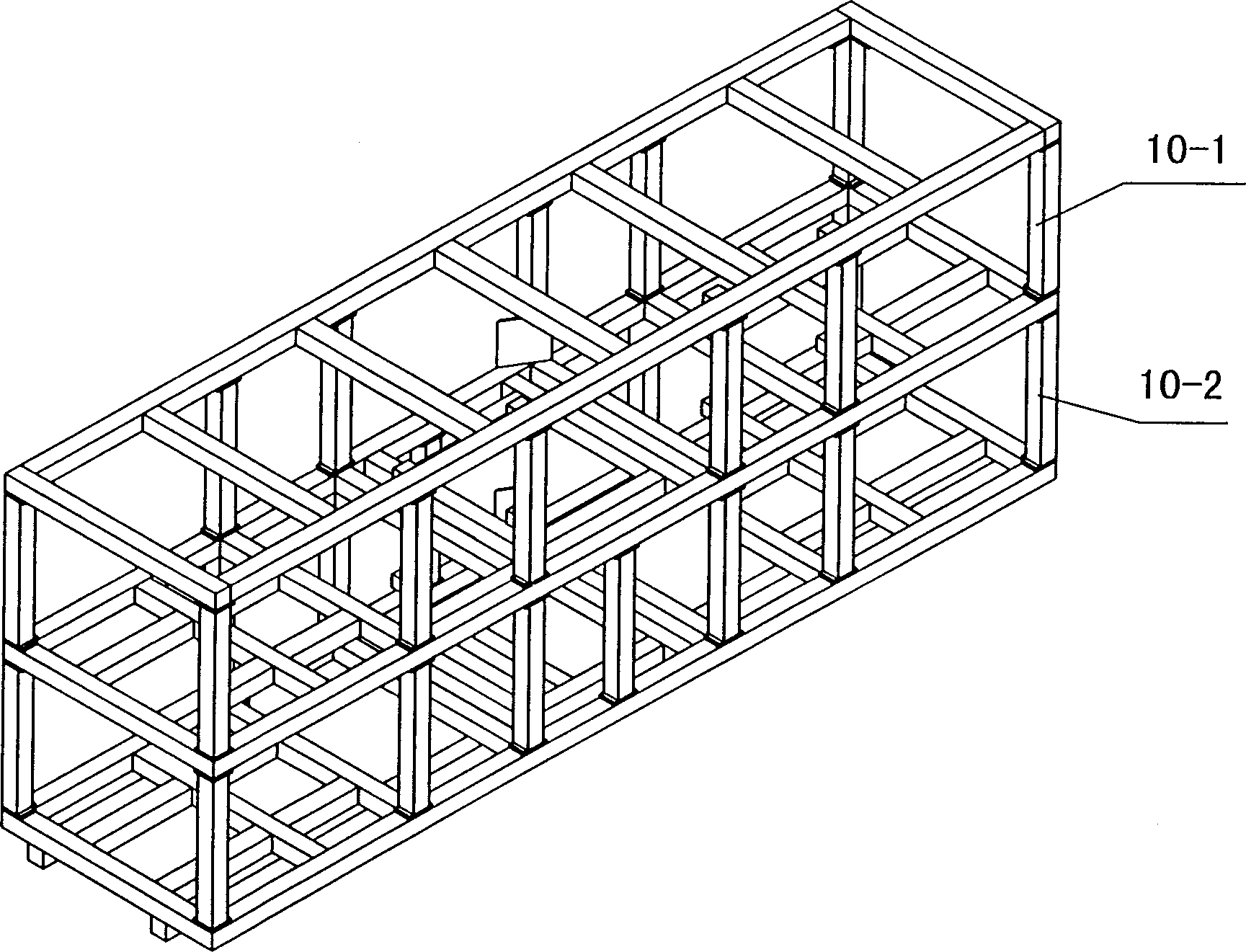

[0027] The fully automatic grinding and drilling machine is also equipped with a frame 10 composed of a beam and a vertical column. All the components of the fully automatic grinding and drilling machine, including the fixture turning mechanism 8 and the fixture frame conveying mechanism 9, are installed on the frame 10. On the beam and the column on the upper frame; the fixture rack conveying mechanism 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com