Method and equipment for producing pressure wave

A pressure wave and generator technology, applied in the field of periodic pressure wave generation, can solve problems such as affecting reliability and efficiency, difficulty in processing and assembly, and performance degradation of refrigerators, so as to improve reliability and efficiency, reduce manufacturing costs, The effect of preventing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

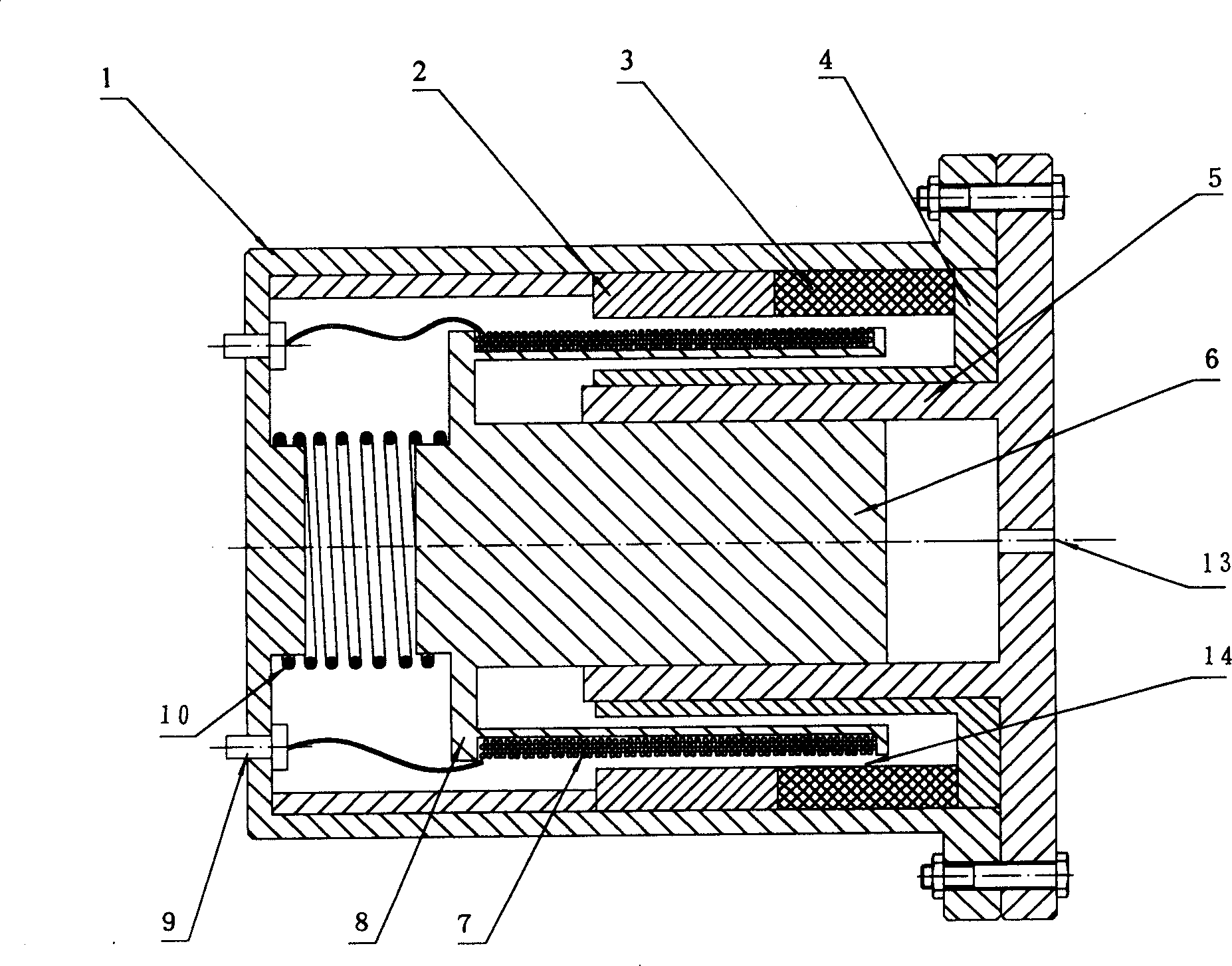

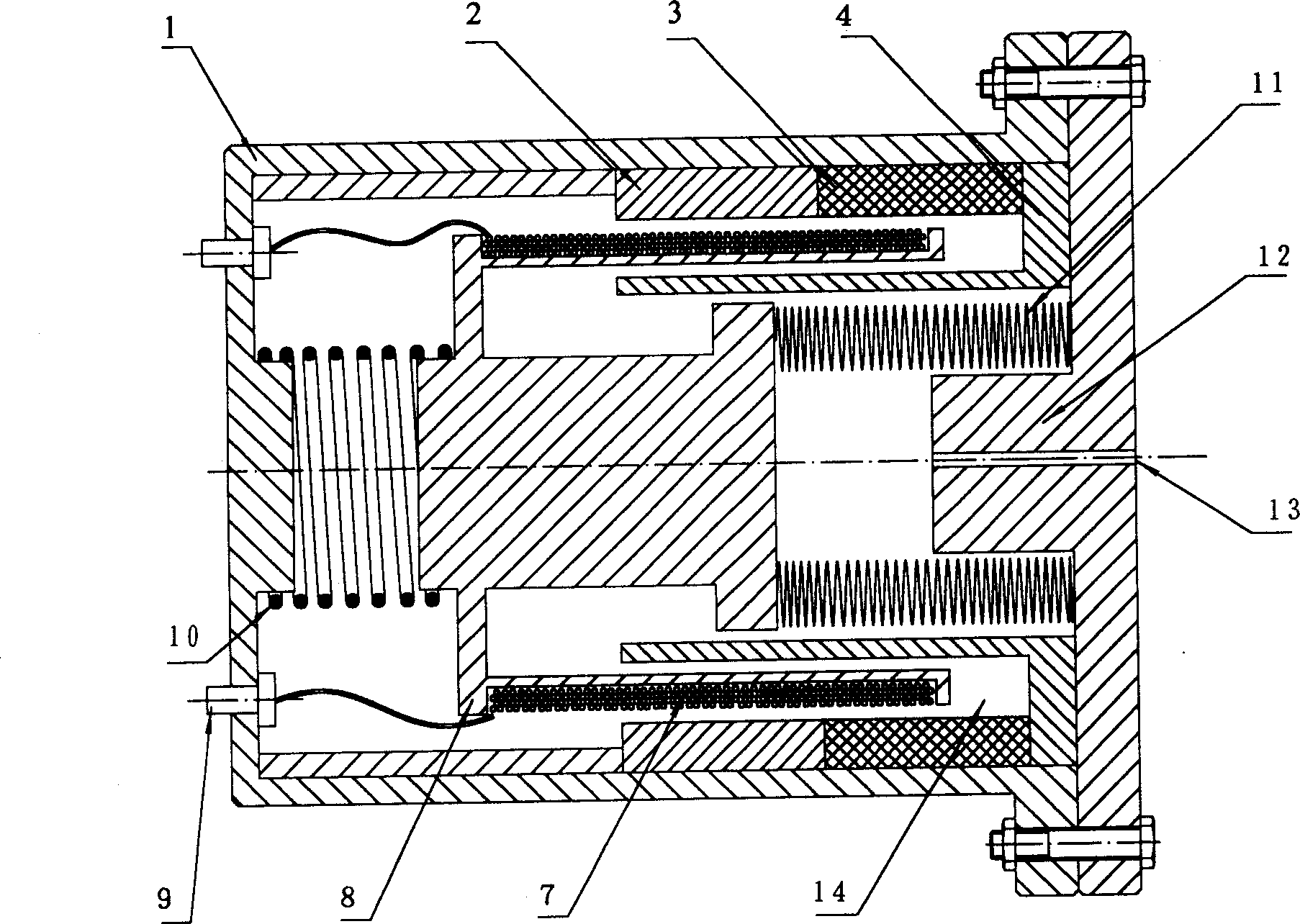

[0026] Example 1: Press figure 2 Make a single-drive pressure wave generator

[0027] The shell 1 of the pressure wave generator is made of alloy aluminum, its purpose is to reduce weight and enhance heat exchange; the permanent magnet 3 is made of NdFeB material with higher magnetic energy level, which can be generated in the slit 14 of the magnetic field circuit to reach The magnetic field strength between 1-1.3T (Tesla) is beneficial to reduce the current on the moving coil 7 of the coil, thereby reducing the Joule heat loss in the coil. The magnetizer A-2 and the magnetizer B-4 are made of DT4 electrical pure iron. The moving coil frame 8 is formed by winding a high-insulation copper wire with a diameter of 1-3 mm on a mountain-shaped alloy aluminum frame. The compressible metal corrugated bellows 12 is welded by multi-layer stainless steel sheet (the market has stereotyped products can choose) between thickness 0.1-0.2 millimeter. The moving coil skeleton 8 and the me...

Embodiment 2

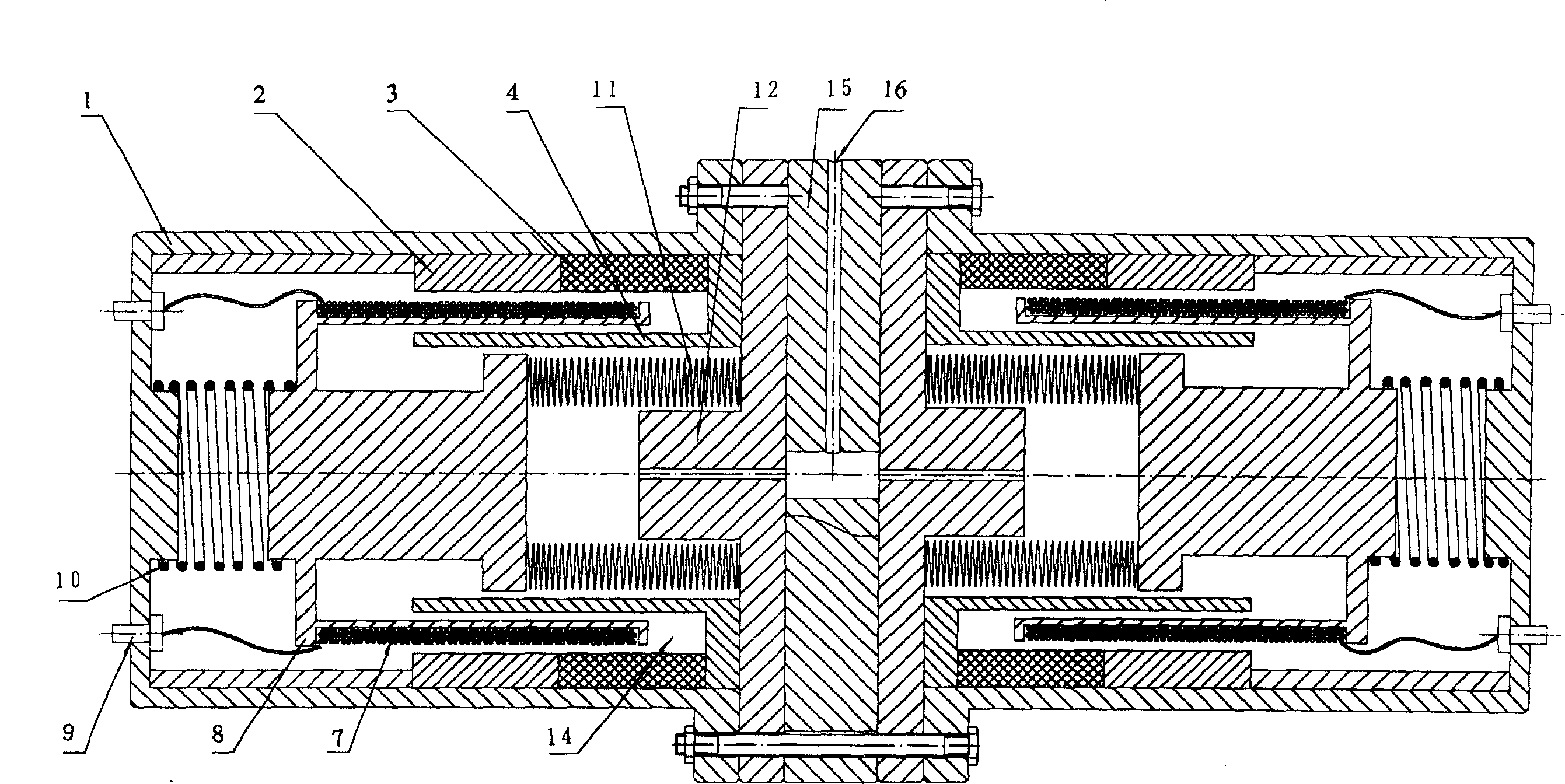

[0033] Example 2: Press image 3 Making a Dual Drive Opposed Pressure Wave Generator

[0034] The material and manufacturing process of the relevant parts of the pressure wave generator are basically the same as those in Implementation 1, except that a pressure wave generator is added, and the left and right sides are connected by a connecting part 15 made of duralumin between the two pressure wave generators. The single pressure wave generator is fixed as a whole, and a channel 16 is processed in the radial direction of the connecting part 15, which is the pressure wave output port. The radially processed channel 16 communicates with the channel 13 of the cylinder 12 of the pressure wave generator . Because the pressure wave generator is bilaterally symmetrical, its vibration and noise are extremely small, and it is more widely used in regenerative refrigerators.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com