Method for producing organoaldehyde prepared by hydroformylating of olefin

A kind of technology of olefin hydroformylation and production method, which is applied in the field of production of organic aldehydes by olefin hydroformylation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

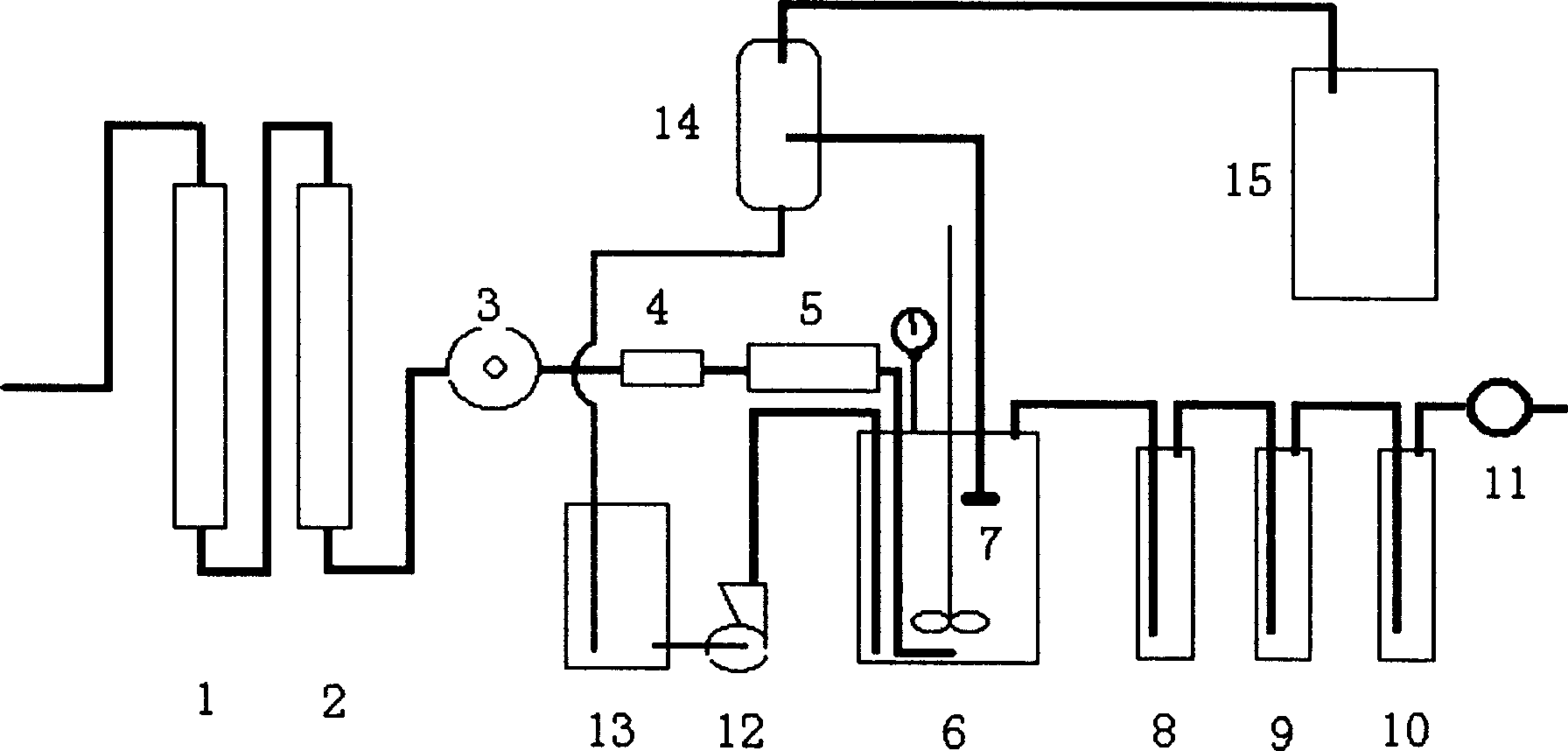

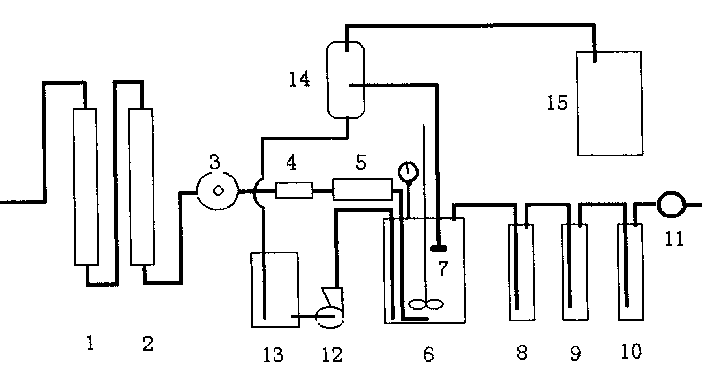

[0026] use figure 1 The process flow is carried out under the following reaction conditions.

[0027] In the production method, the catalyst is prepared by a heterogeneous catalyst homogeneous method, and organic aldehyde products are prepared from synthesis gas and olefin mixed gas. Syngas is mainly composed of H 2 , CO and olefins, in this case ethylene, and H 2 / CO volume ratio is 1.0-4.0, syngas / C 2 h 4 The volume ratio is 0.5-3.0; the reaction conditions of hydroformylation are: the reaction temperature is 80-150°C, the reaction pressure is 0.05-10Mpa, and the air velocity of the mixed gas is 100-10000h -1 .

[0028] The catalytic reaction for preparing various organic aldehydes by hydroformylation of olefins is carried out on a rhodium-based catalyst modified by organic phosphine ligands supported by silica.

[0029] The products of various organic aldehydes produced by olefin hydroformylation have a boiling point of 46-50°, and the fraction contains at least 99% p...

Embodiment 2

[0032] According to the process flow described in Example 1, the reaction was carried out under the following reaction conditions.

[0033] Propylene in this example, and H 2 / CO volume ratio is 1.0-4.0, syngas / C 3 h 6 The volume ratio is 0.5-3.0; the reaction conditions of hydroformylation are: the reaction temperature is 80-150°C, the reaction pressure is 0.05-10Mpa, and the air velocity of the mixed gas is 100-10000h -1 .

[0034] The invention relates to a production method for preparing various organic aldehydes by hydroformylation of olefins on a rhodium-based catalyst modified by organic phosphine ligands supported by silica.

[0035] The product of various organic aldehydes produced by olefin hydroformylation has a boiling point of 75°, and the fraction contains at least 99% butyraldehyde by weight, wherein the n-butyraldehyde / isobutyraldehyde ratio is 2-10.

[0036] In addition, in this embodiment, the reaction product is condensed and collected through the produc...

Embodiment 3

[0038] According to the process flow described in Example 1, the reaction was carried out under the following reaction conditions.

[0039] 1-hexene in this example, and H 2 / CO volume ratio is 1.0-4.0, syngas / 1-C 6 h 12 The volume ratio is 0.5-3.0; the reaction conditions of hydroformylation are: the reaction temperature is 80-150°C, the reaction pressure is 0.05-10Mpa,

[0040] The invention relates to a production method for preparing various organic aldehydes by hydroformylation of olefins on a rhodium-based catalyst modified by organic phosphine ligands supported by silica.

[0041] The products of various organic aldehydes produced by hydroformylation of olefins have a boiling point of ca.

[0042] Take by weighing 15ml1-hexene and 60ml hexanaphthene and place in the slurry bed reactor, use inert gas (such as N 2 or Ar, 1.0MPa) to replace the air in the reactor three times, and then use CO and H from the pipeline 2 (CO / H 2 =1) mixed gas, the gas is first purified t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com