Structure and method for packaging colour light-emitting diode with stacked wafer

A technology of light-emitting diodes and packaging structures, which is applied to electrical components, circuits, semiconductor devices, etc., and can solve problems such as difficult heat dissipation, shortened life, and difficult and precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

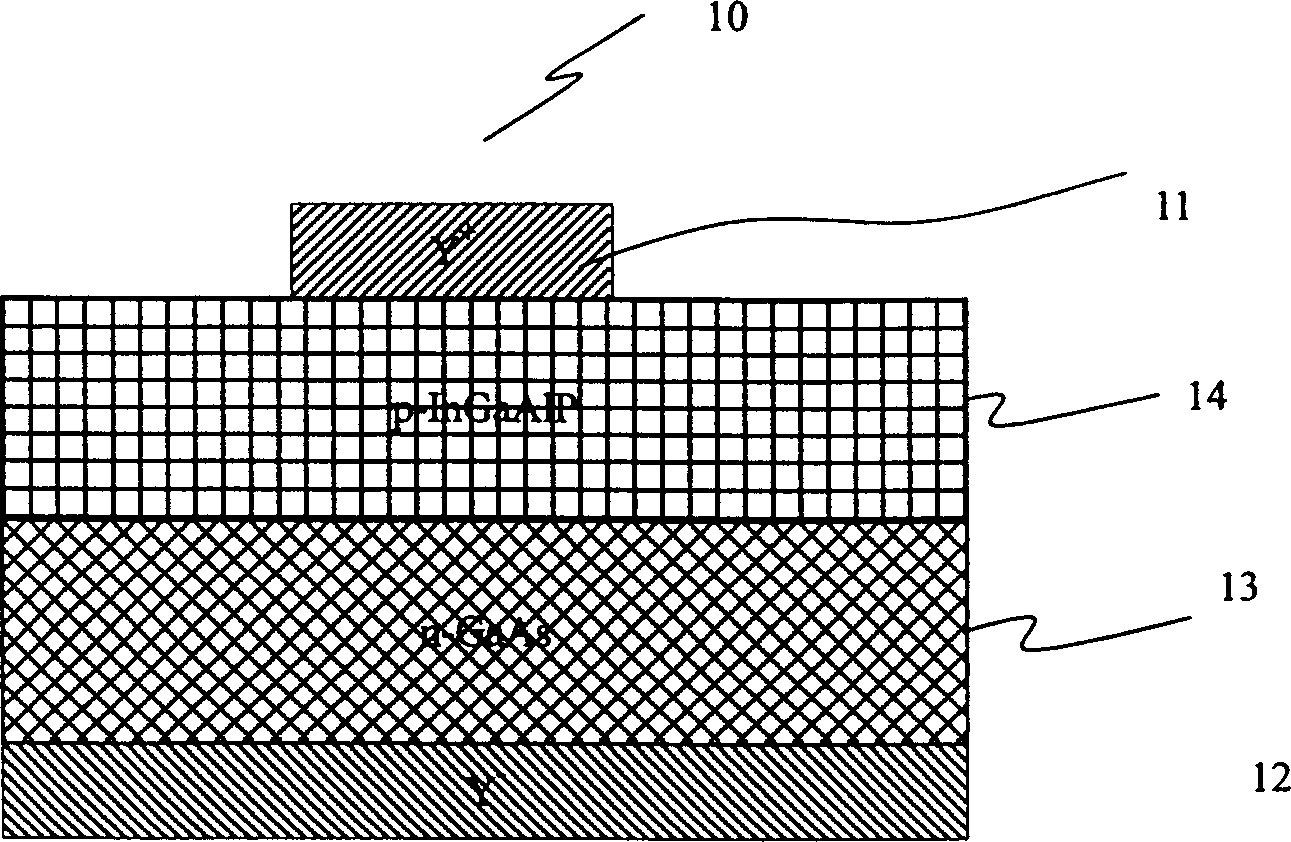

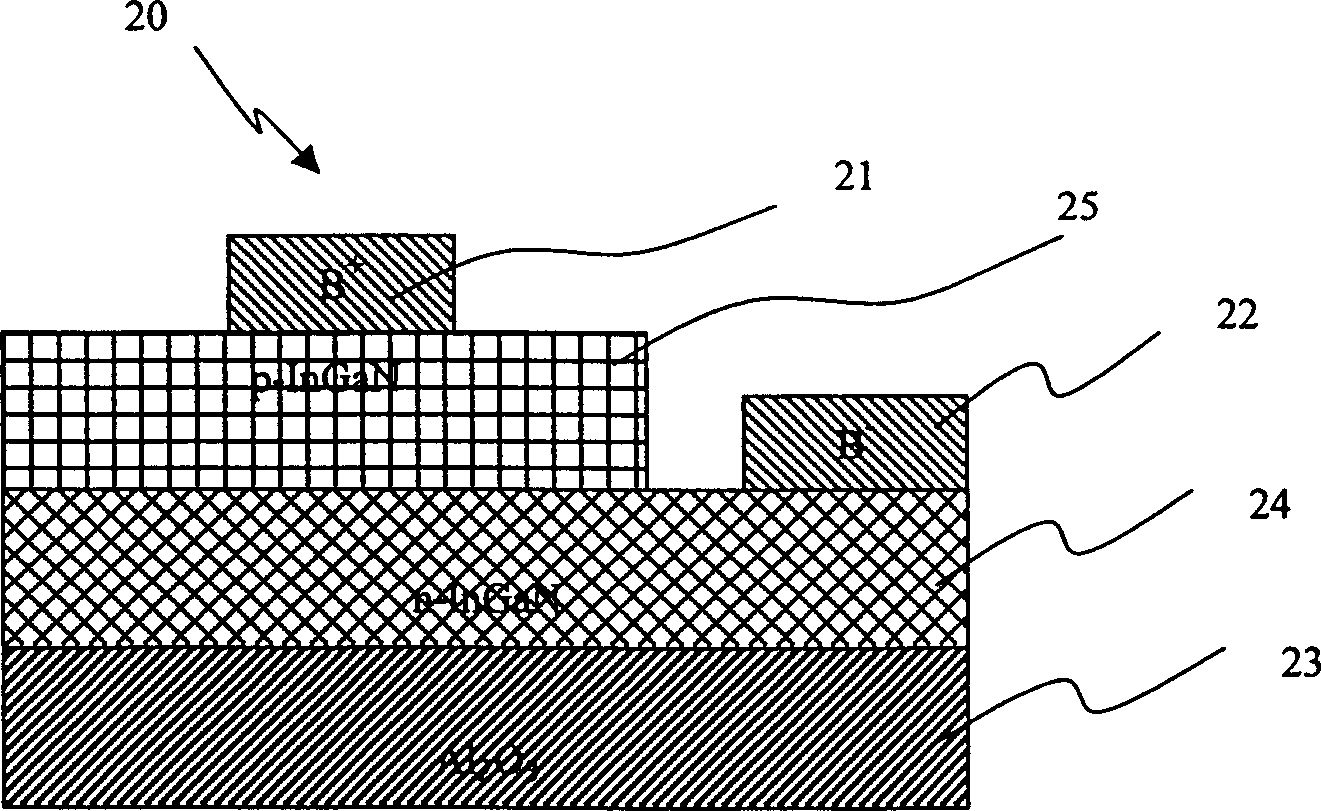

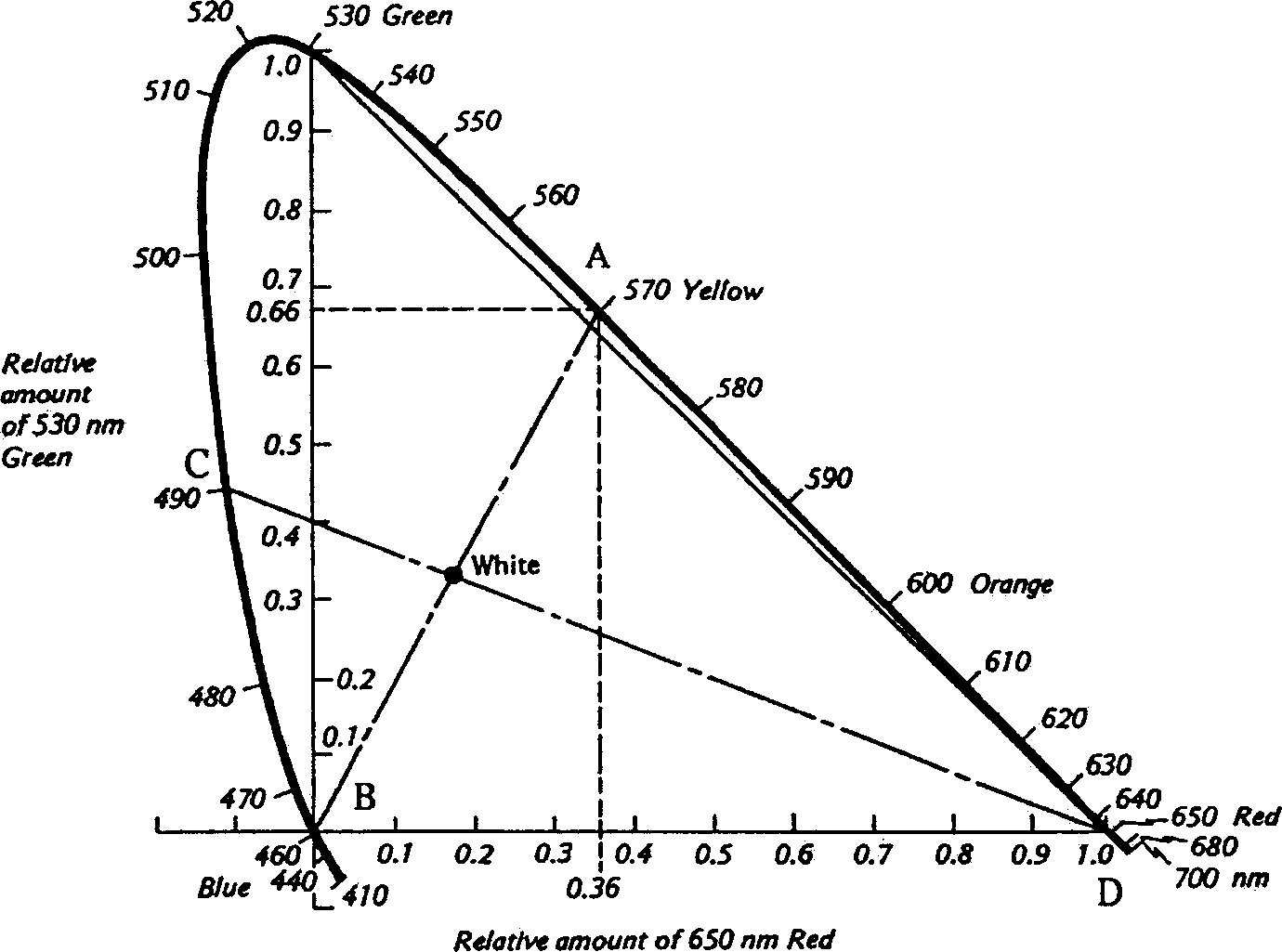

[0065] The content of the present invention can be illustrated by the following embodiments and the accompanying drawings. The various LED materials used in the present invention are not limited, as long as they are LED chips capable of emitting three primary colors of red, green, blue and yellow. The wafer can be produced by a known method, and can be manufactured according to the specifications (size, bias value, brightness, color, metal contact material, etc.) specified in the present invention. Structures according to the present invention should be measured and graded prior to encapsulation, using the same grade or the same type (eg, bias, brightness, color) for the same encapsulation.

[0066] The invention includes a printed circuit board with a pattern of a metal reflective layer on it for die bonding. After the first chip is bonded, the second chip is stacked on the first chip for die bonding. The method can be thermal fusion, ultrasonic fusion or bonding with transp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com