Structure and part for electric cable connection and making method thereof

A technology for electrical connection and power cable, which is applied in the direction of cable joints, cable accessories, cable installation, etc., and can solve the problems of increasing the length and size, the overall length of the connecting part, and increasing the manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

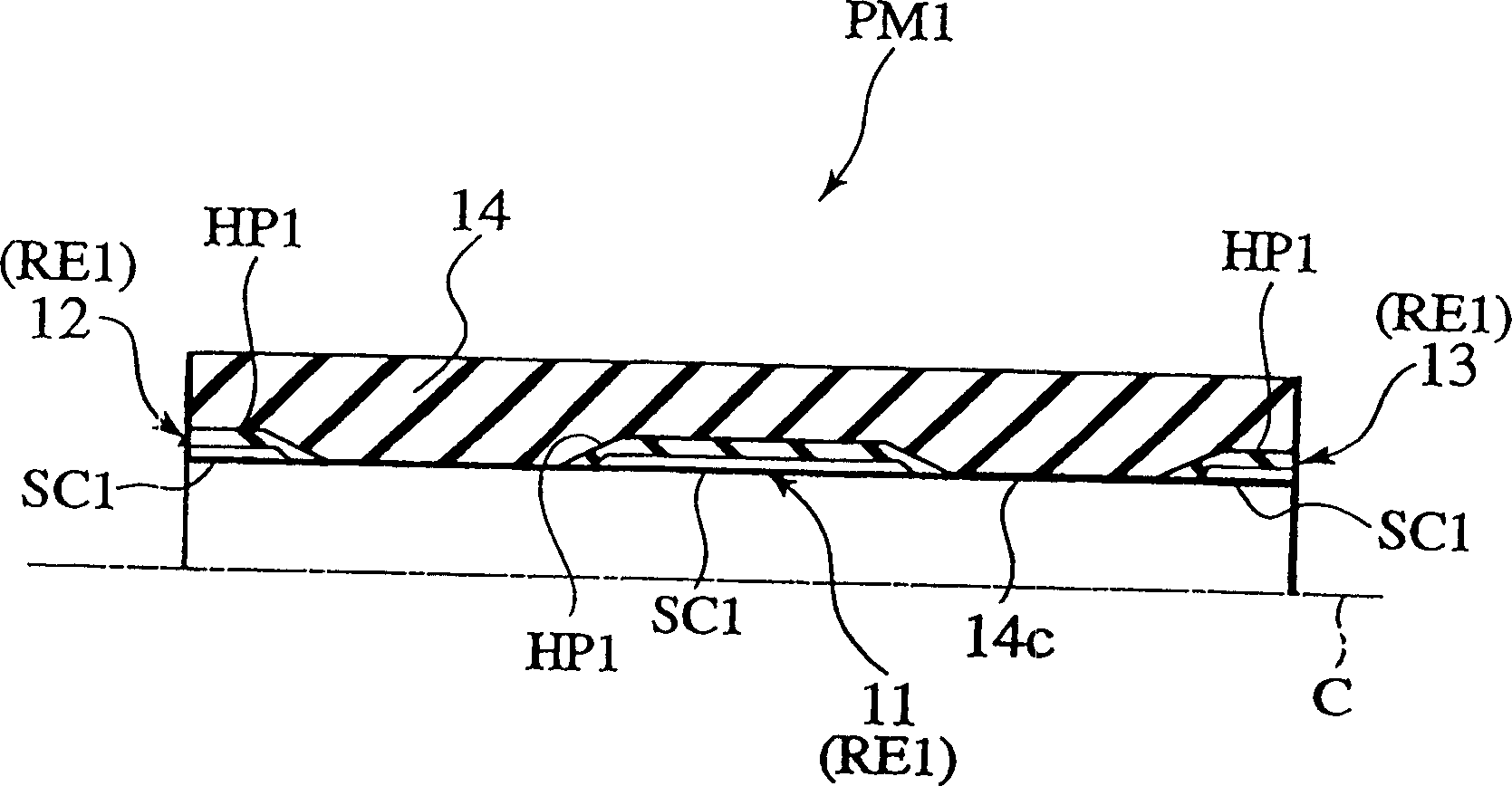

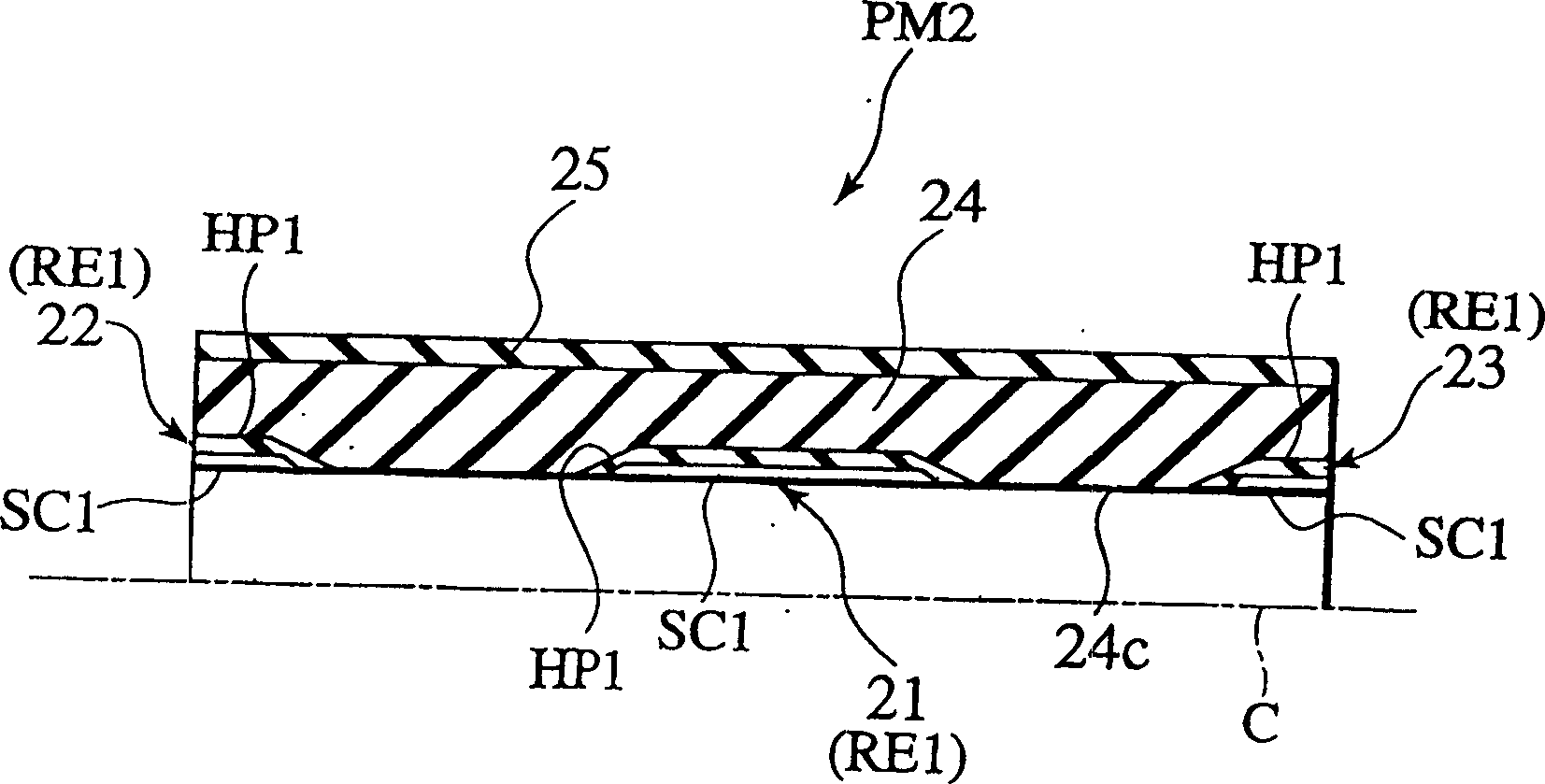

[0060] The above and other objects, features, functions and effects of the present invention are referred to below Figure 1-Figure 8 The description of the examples will be more clear. In the drawings, the same elements are denoted by the same reference numerals.

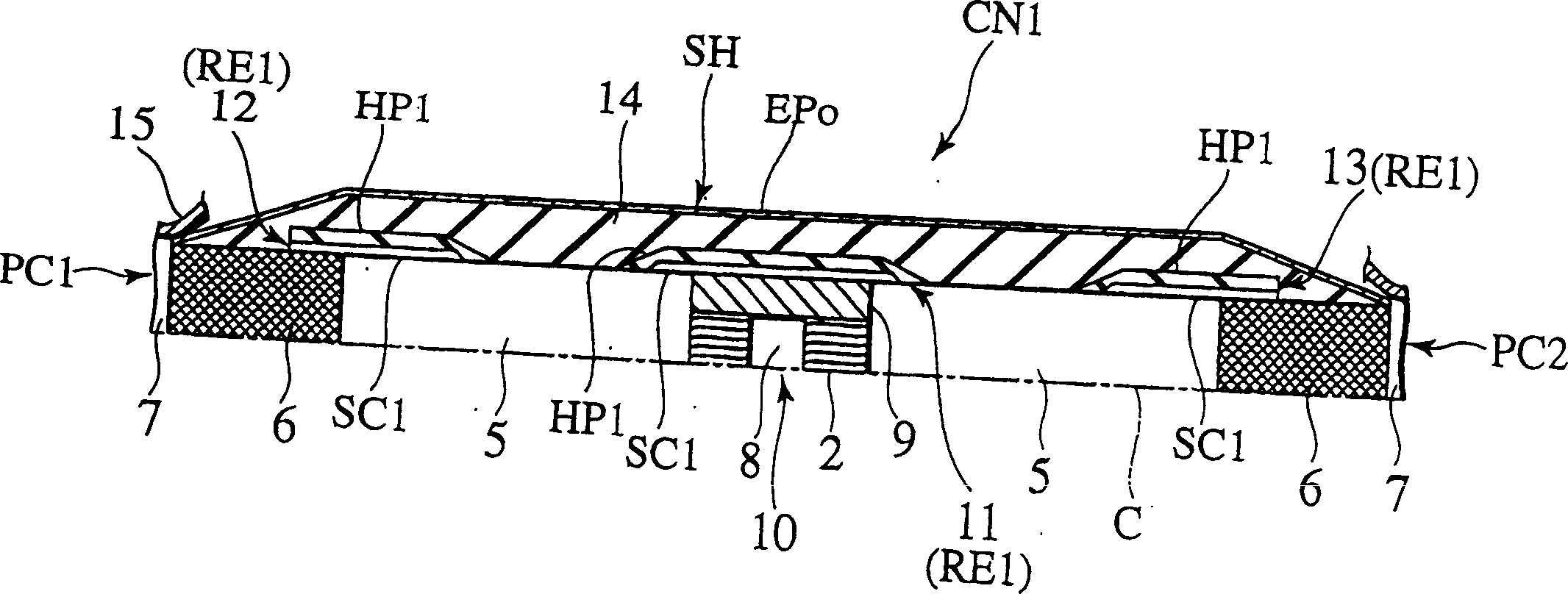

[0061] figure 1 The connection structure CN1 of the plastic insulated power cables PC1, PC2 related to the first embodiment of the present invention is shown.

[0062] This connection structure CN1 is composed of: the core wire connection part 10 electrically connecting the exposed conductor cores 2, 2 of the left and right power cables PC1 and PC2, and connecting the exposed shielding screens 6, 6 of the power cables PC1 and PC2. The shield connection portion SH for electrical connection between these core wire connection portions 10 and the shield connection portion SH is used to form the exposed insulating cross-linked polyethylene insulators 5 and 5 of the power cables PC1 and PC2 filled between these core w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com