Magnetic suspension type micro motion system

A micro-motion and magnetic levitation technology, applied in the field of magnetic variable systems, can solve problems such as small motion range, low motion accuracy, and difficulty in realizing high-precision nano-scale motion, achieving the effect of frictionless and guaranteed motion accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

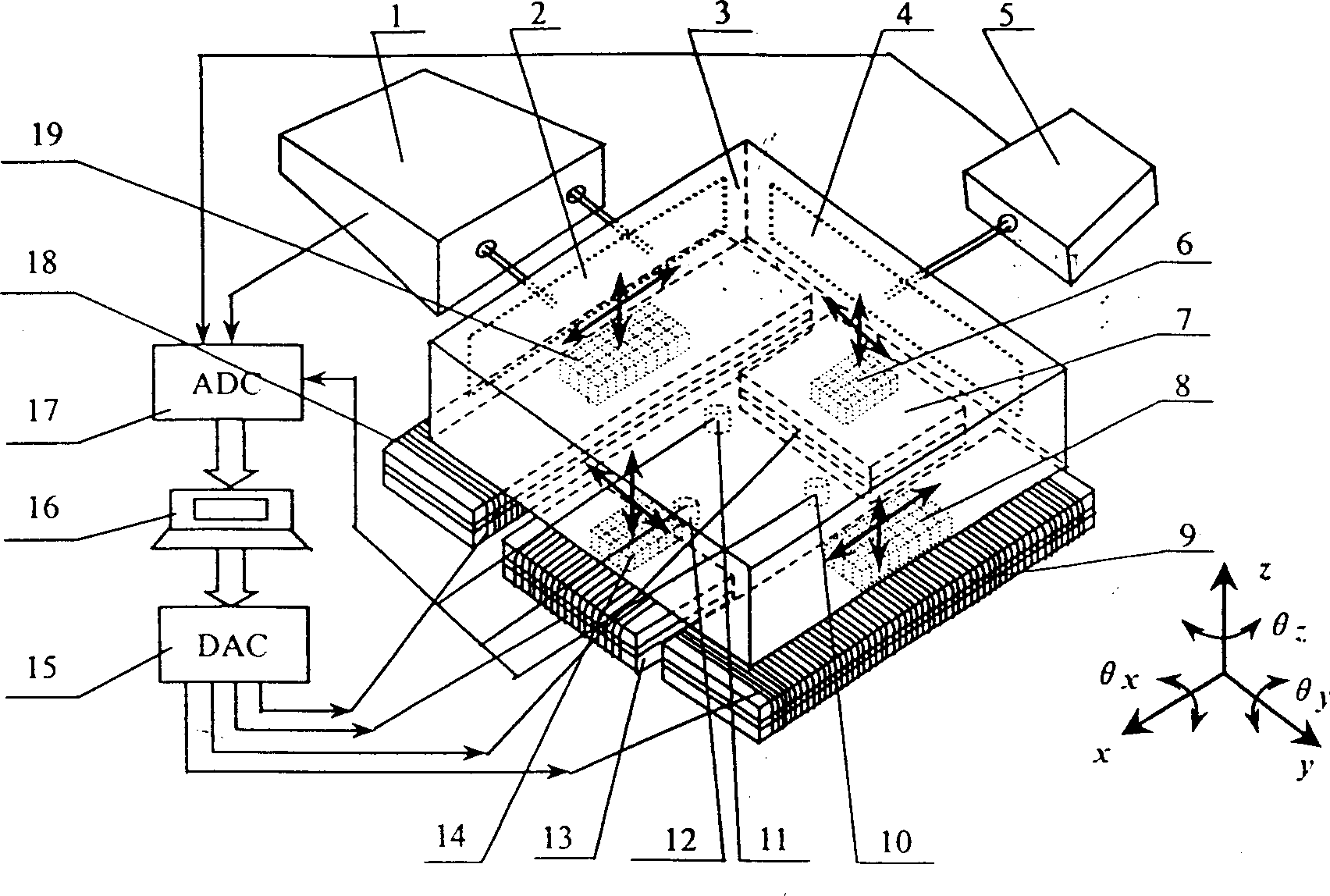

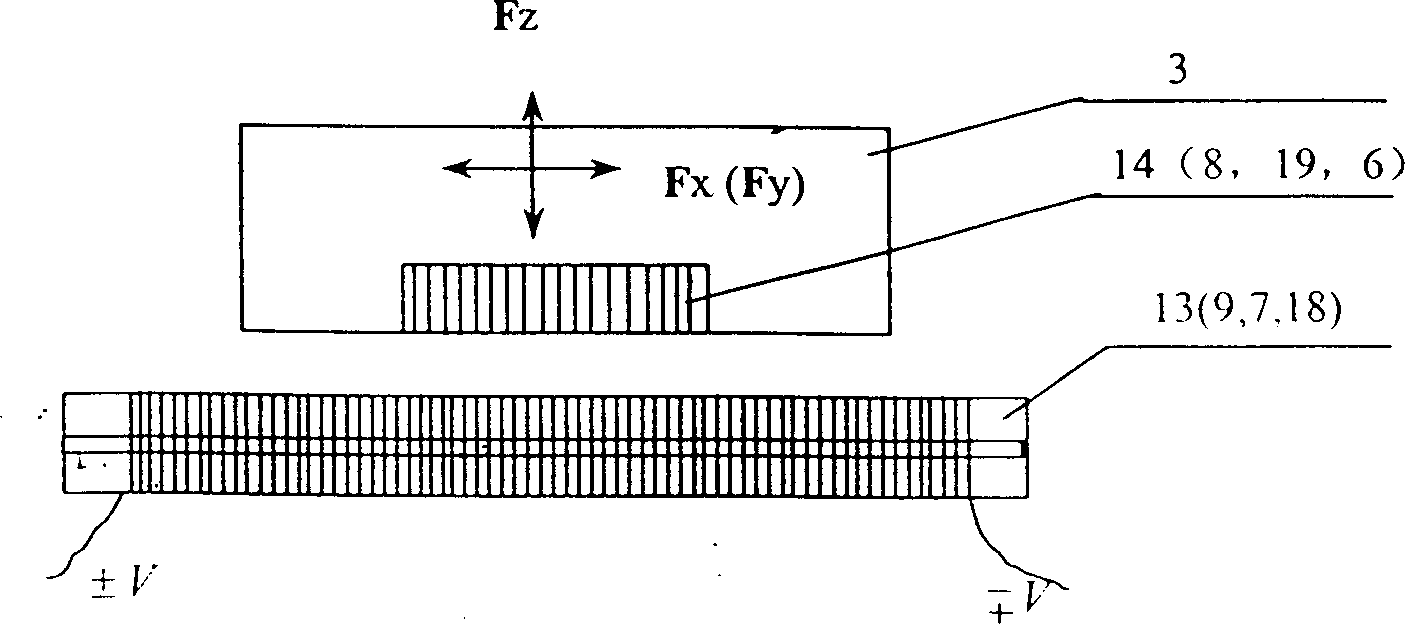

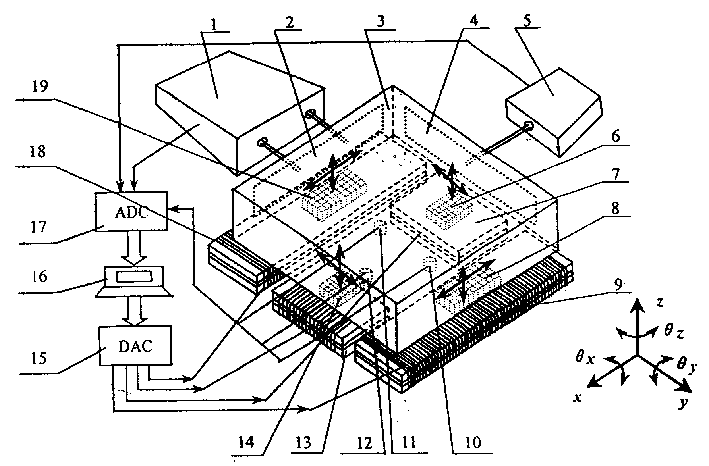

[0013] like figure 1 As shown, it includes a laser nanometer micro-displacement and micro-angle measuring instrument 1, two measuring mirrors 2, 4, a motion platform 3, a laser heterodyne nano-interferometer 5, four permanent magnet arrays 8, 19, 6, 14, four A group of stator windings 9, 18, 7, 13, three capacitive sensors 10, 11, 12, a digital-to-analog converter 15, a computer 16, and an analog-to-digital converter 17; the first permanent magnet array is respectively embedded in the bottom of the four sides of the motion platform 3 8. The second permanent magnet array 19, the third permanent magnet array 6, the fourth permanent magnet array 14, the first and second permanent magnet arrays 8, 19 correspond, the third and fourth permanent magnet arrays 6, 14 correspond, in The first and second stator windings 9 and 18 are installed respectively below the first and second permanent magnet arrays 8 and 19, and the third and fourth stator windings 7 and 13 are respectively instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com