Top layer for absorption products

A technology of absorbent products and layer materials, applied in the field of absorbent products, can solve the problems of unsanitary, uncomfortable feeling, weak fusion connection and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

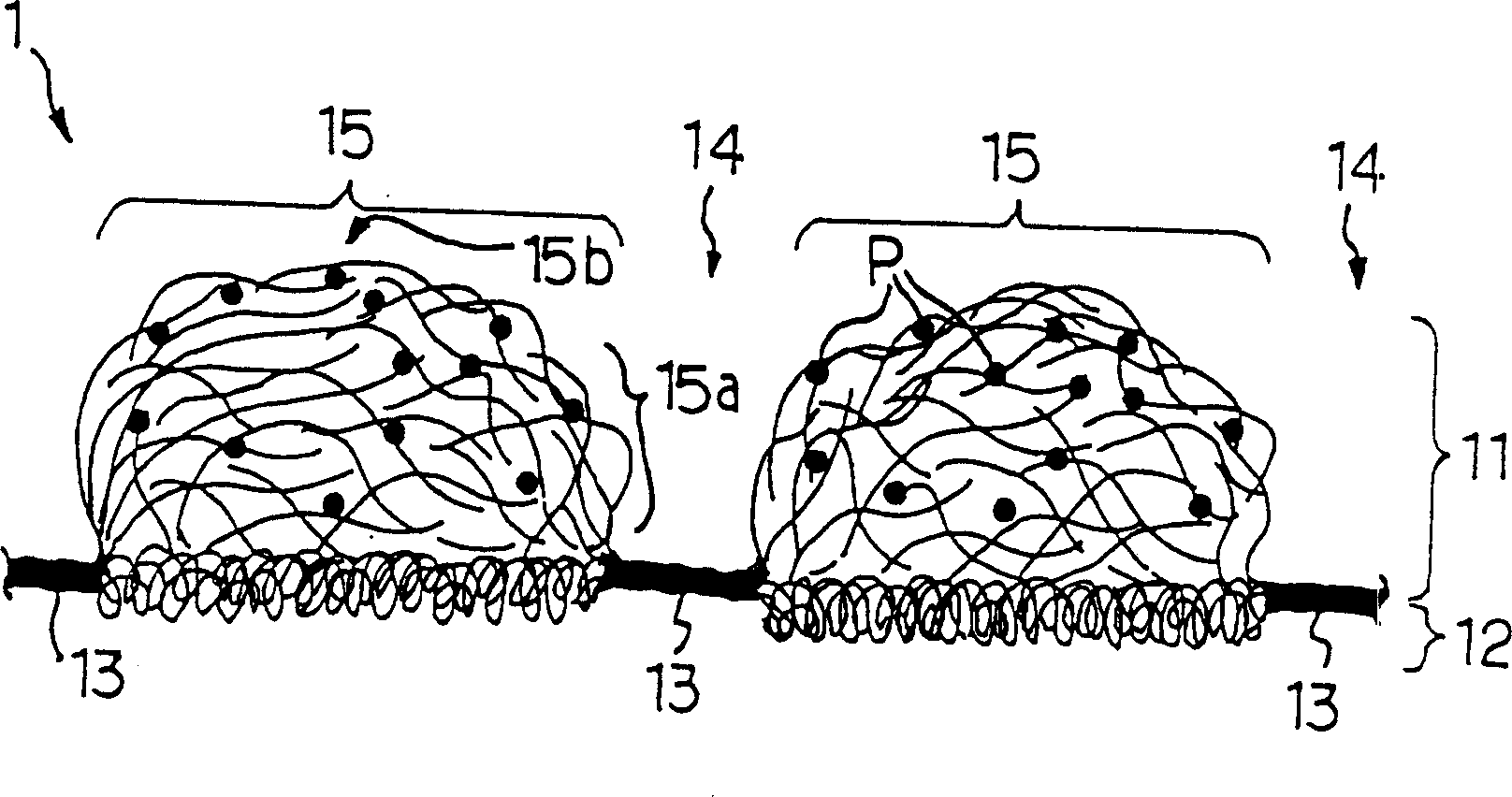

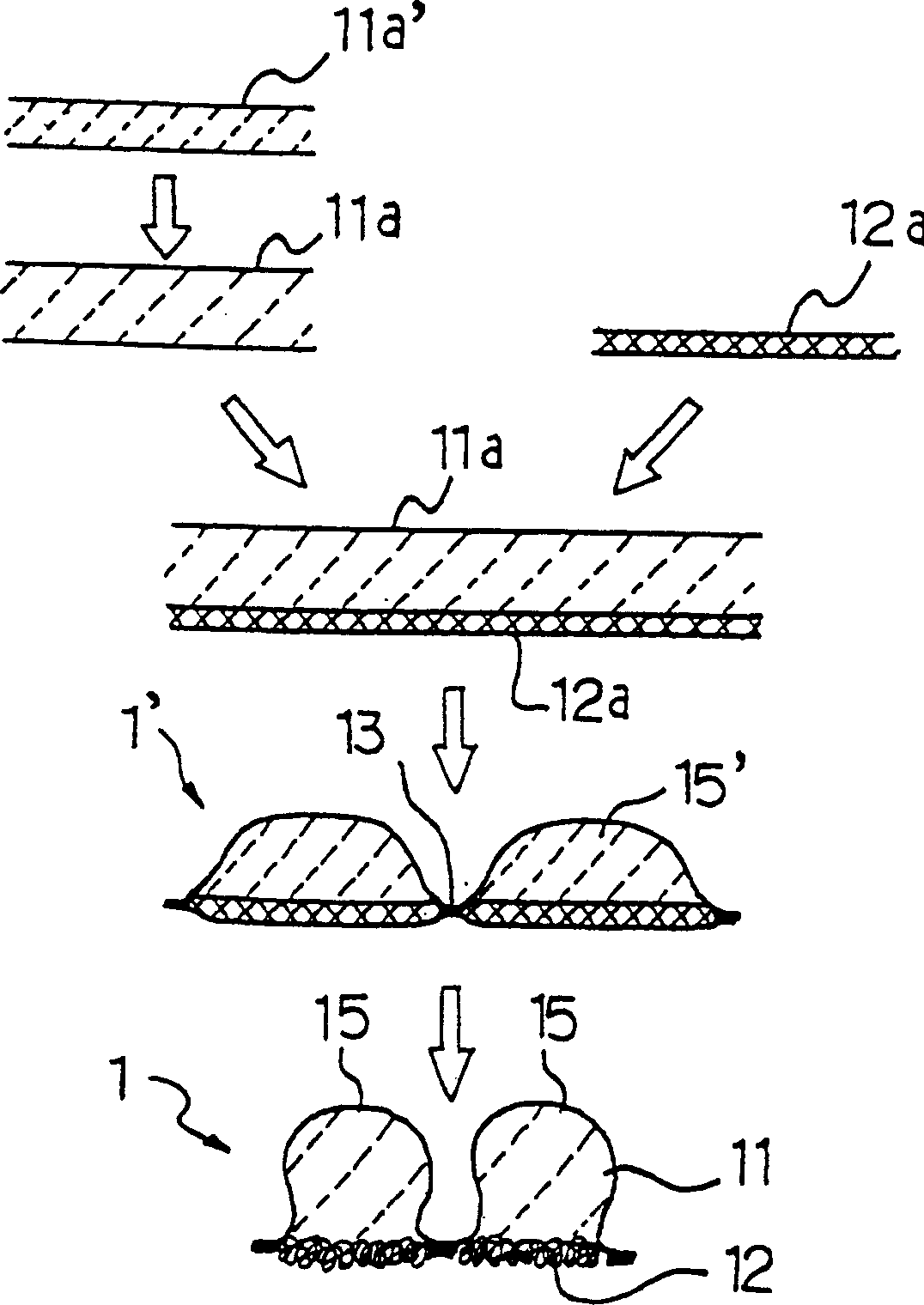

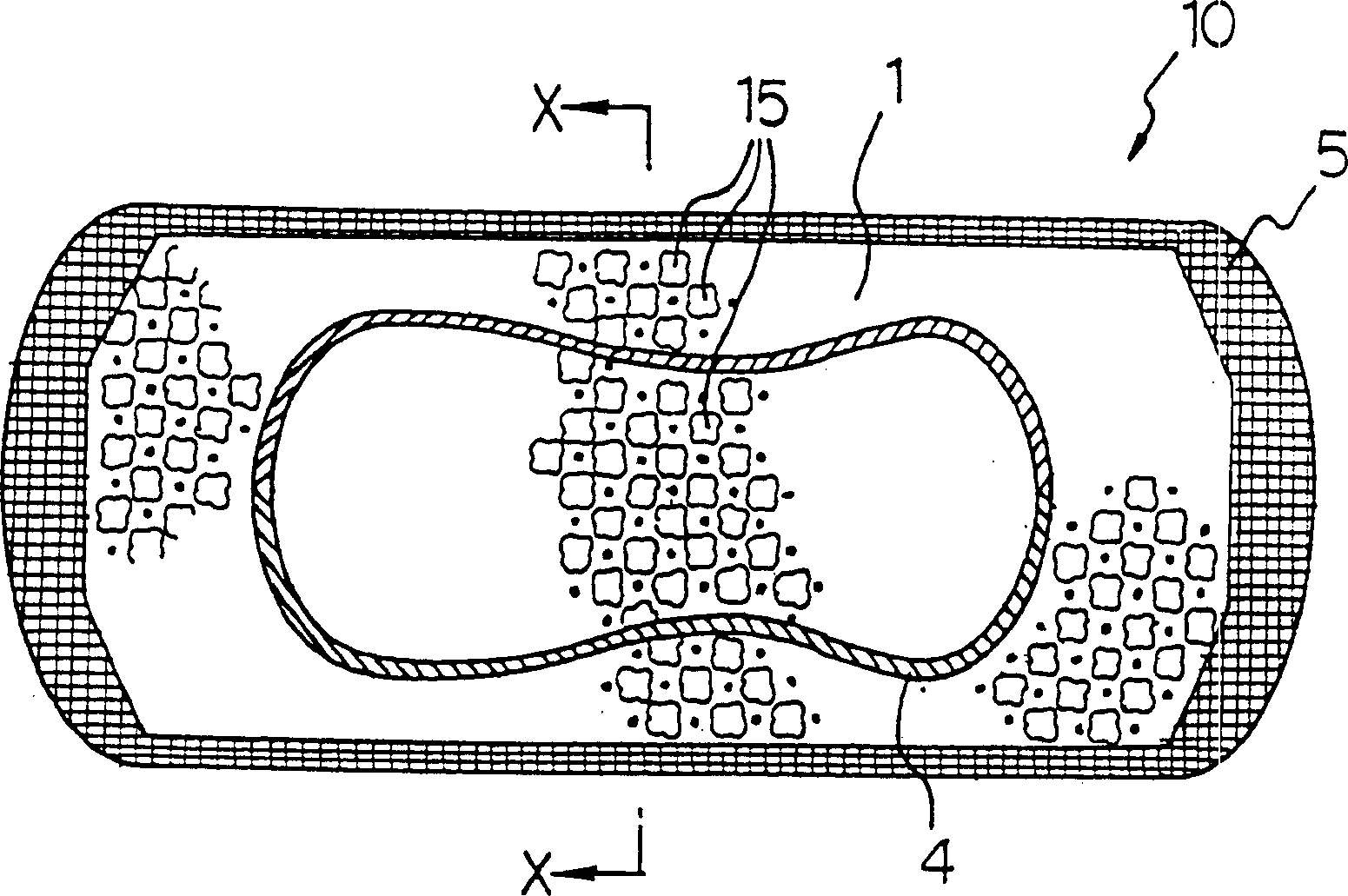

[0092] The present invention will now be described in more detail with reference to Examples. All percentages and ratios are by weight unless otherwise indicated. Preparation of the top layer:

[0093] Heat-fusible sheath-type conjugate fibers (2.2 dtex x 51 mm) (available from Daiwabo Co.) consisting of a polyethylene terephthalate core and a polyethylene sheath were carded into a web and wound at 120 Heat treatment at ℃ to melt-bond the intersection points of fibers 2 Base-weight non-woven fabric. The non-proof cloth has a thickness of 1 mm and a thickness of 0.025 g / cm under hot air treatment at 70 ° C. 3 Lofty non-woven fabric of bulk density (material forming the first layer).

[0094] Separately, the fiber CPP (2.2dtex * 51 millimeters that can be obtained from Daiwabo Co., Ltd) that can be automatically crimped into a spiral shape is carded to have 35g / m 2 Basis weight web (material forming the second layer).

[0095] The material forming the first layer and the m...

Embodiment 2

[0102] Make top layer with the same method as embodiment 1, difference will have thickness 0.9 millimeter, apparent density 0.013g / cm 3 And base weight 12g / m 2 The bulky non-woven cloth used as the material forming the first layer, and the fiber web forming the second layer partially connected with the bulky non-woven fabric shrunk at an area shrinkage rate of 30%.

Embodiment 3

[0104] A top layer was prepared in the same manner as in Example 2, except that the percent area shrinkage was changed to 15%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com