Single Channel radial Drum type device for filtering small particles in tail gas of diesel cars

A filtering device, a cylindrical technology, applied in the direction of exhaust devices, mufflers, engine components, etc., can solve the problems of excessive exhaust back pressure rise, reduction of effective volume of filter body, blockage, etc., and achieve the goal of reducing environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

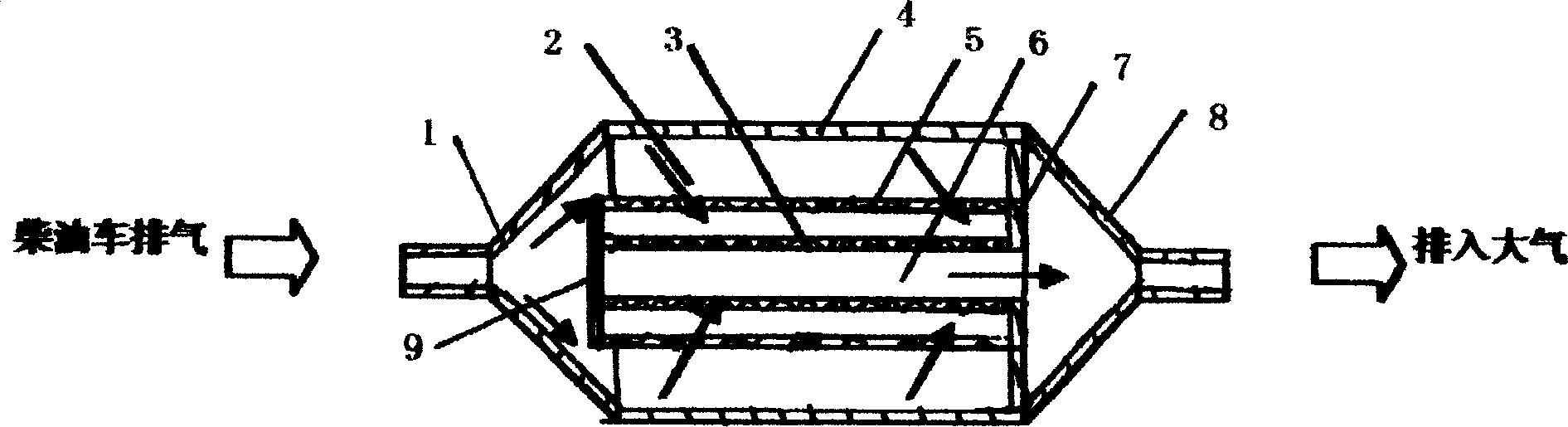

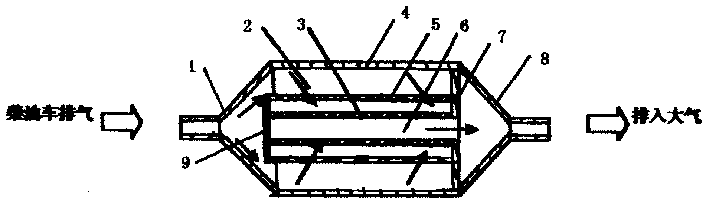

[0010] figure 1 Shown is a schematic diagram of the structure of a single-channel radial cylindrical diesel vehicle exhaust particulate filter device. The device is composed of an inlet cone 1 and an exhaust cone 8 connected to the two ends of the shell 4 and a filter layer installed in the shell. The coarse filter plate 5 is outside, and the fine filter plate 3 is concentrically fixed on the rear packaging circle. On the disc 7, the other end is fixed by the front encapsulation disc 9 in the position of the two-layer stencil, and seals the central channel opening at the air inlet end, and the outer circle 5 of the rear encapsulation disc and the exhaust port end of the shell 4 are connected together. The engine exhaust enters the outer channel 2 from the cone 1, and enters the fine filter plate 3 from the coarse filter plate 5, and is filtered by a metal composite plate or other types of composite filter materials. The composite filter material includes a composite wire mesh ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com