Dual in-line package type double-contact text fixture

A test fixture and double-contact technology, applied in electronic circuit testing, single semiconductor device testing, etc., can solve the problems of poor contact between the test fixture and the measured object, and can not be completely improved, so as to reduce the test cost and reduce the probability of poor contact , the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

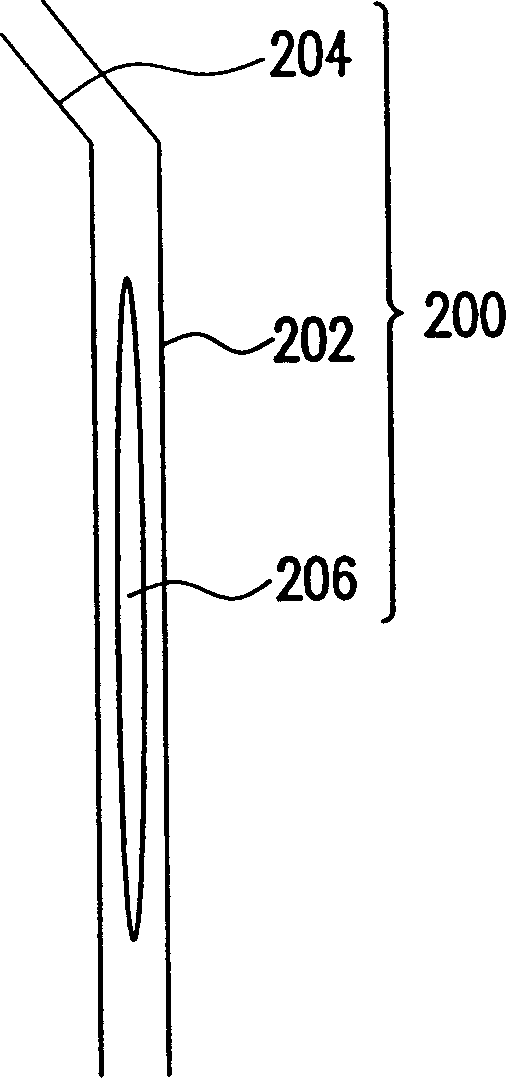

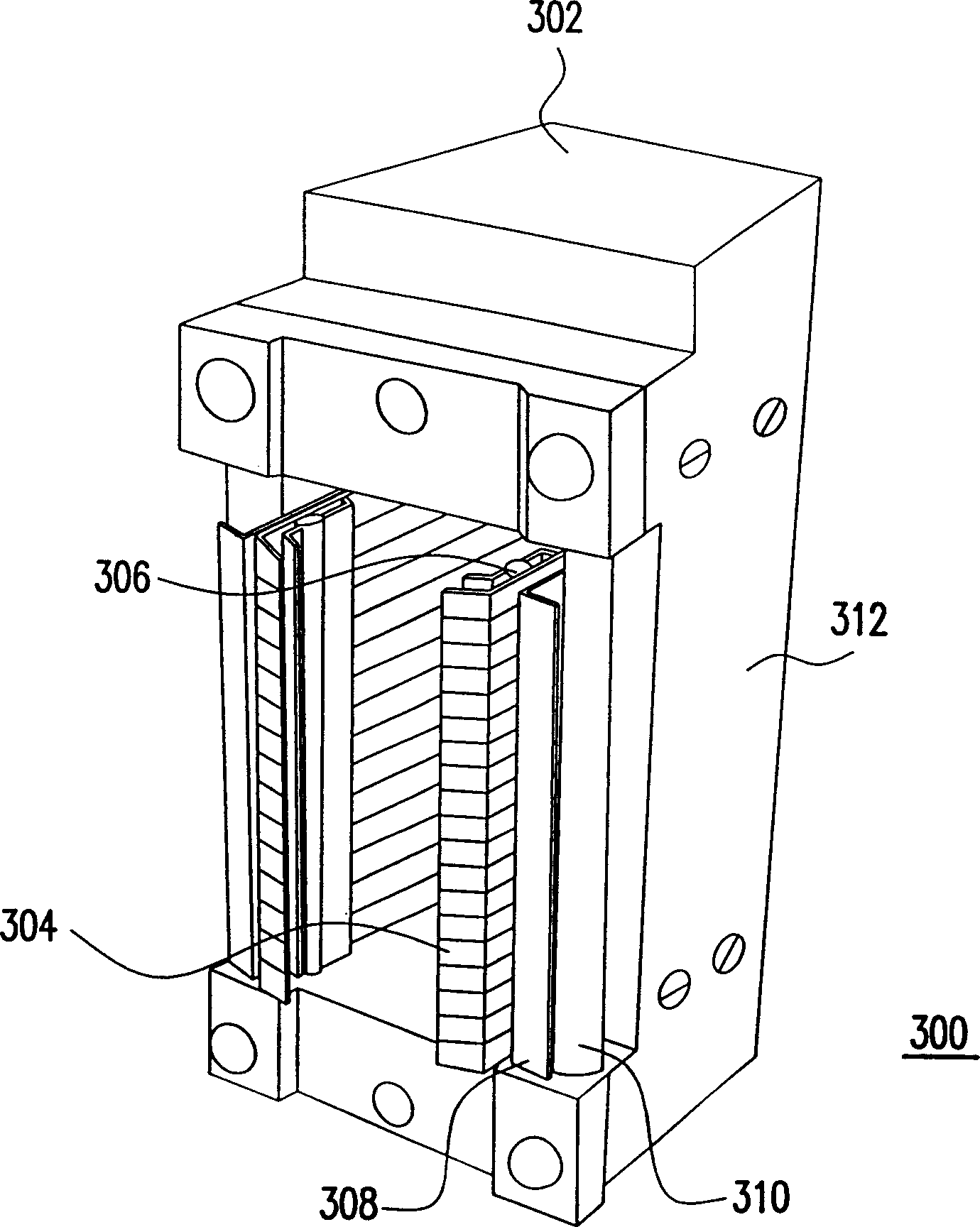

[0047] Figure 3 to Figure 5 It is a schematic diagram of a dual-contact test fixture in a double-sided in-line packaging type according to a preferred embodiment of the present invention. Image 6 It is a front view of a dual-contact contact sheet and a side view of a contact pin in a preferred embodiment of the present invention.

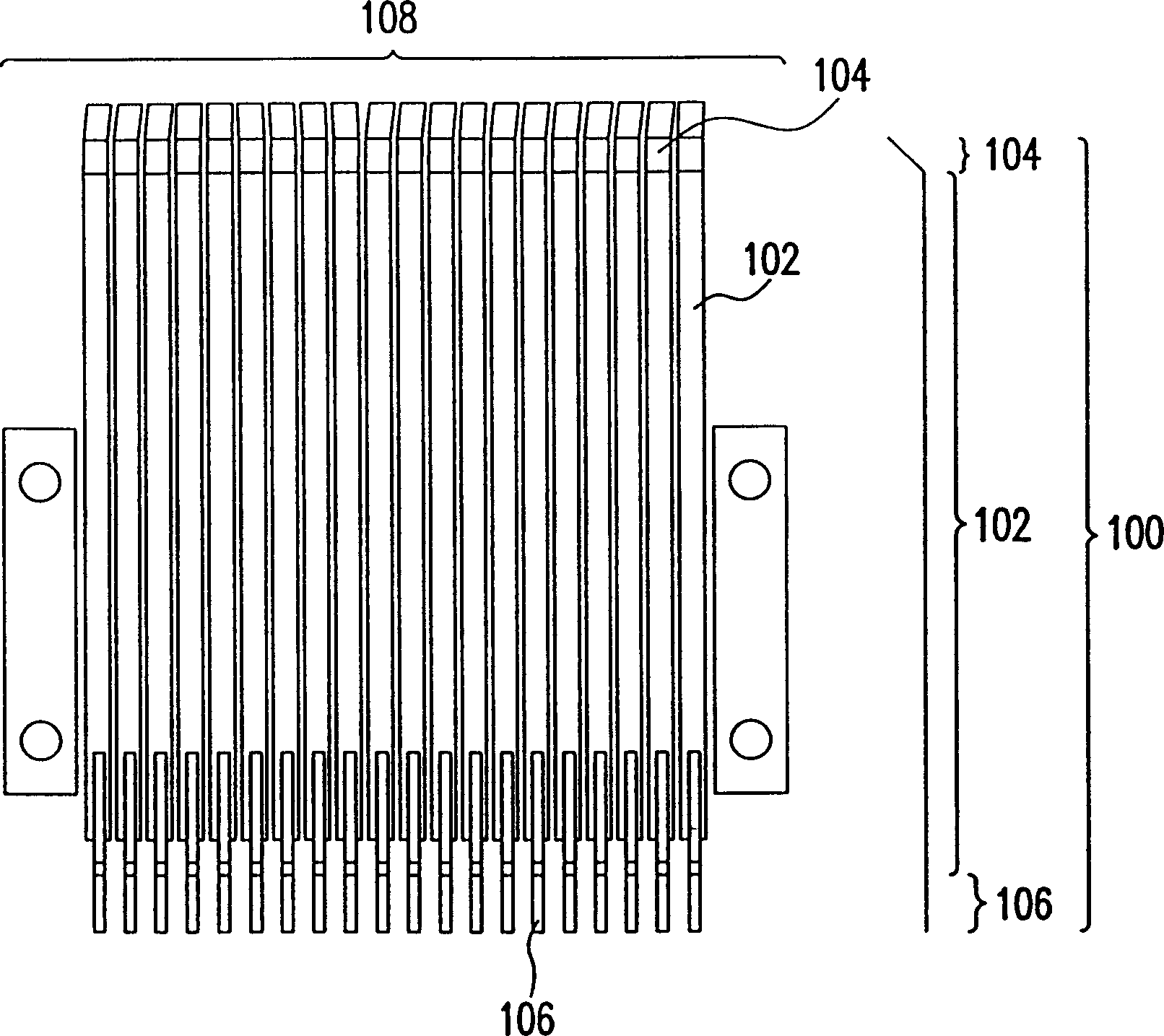

[0048] Please also refer to Figure 3 to Figure 6 As shown, the double-contact test fixture 300 of the present invention is composed of a main body 302 , a double-contact contact piece 304 , a metal ground piece 308 , a soft insulating piece 306 , a push rod 310 , and a cover 312 . Two double-contact contact pieces 304 are respectively located on the two corresponding side walls 302a of the main body 302, two soft insulation pieces 306 are respectively located on the double-contact contact piece 304, and two metal grounding pieces 308 are respectively located on the soft insulation pieces 306 The upper and second push rods 310 are respectively l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com