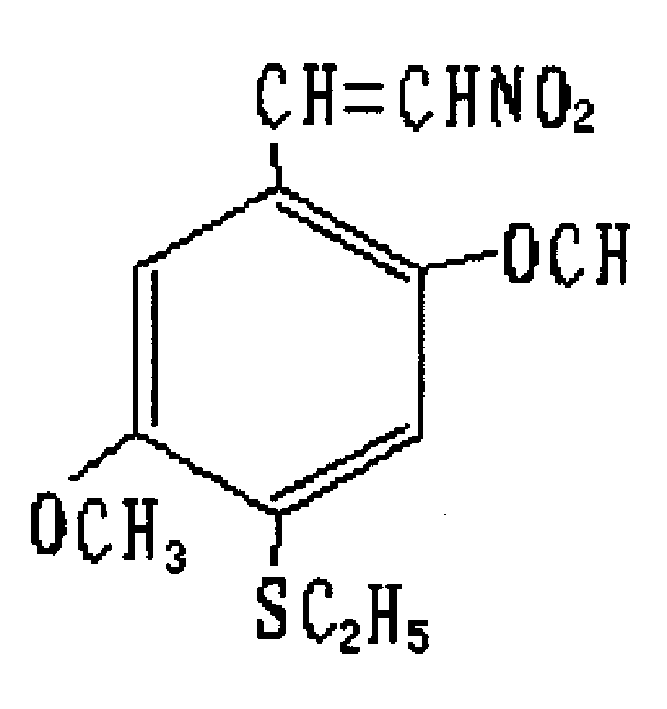

2,5-dimethoxy-4-ethyl sulfide-beta-nitrostyrolene and preparation process and use thereof

A kind of technology of nitrostyrene and dimethoxy thiophenol, applied in 2 fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Add 105ml of dichloroethane and 13.5g of p-xylylene dimethyl ether into a 250ml three-necked flask, stir to dissolve, cool in an ice bath (0-10°C), add 26.5ml of chlorosulfonic acid and 10ml of thionyl chloride dropwise under stirring, and react After 2 hours, it was poured into 280ml of ice water under stirring, and the lower oil layer was separated, and dichloromethane (recovery) was evaporated to obtain yellow solid 2,5-dimethoxybenzenesulfonyl chloride, with a dry weight of 19.8g and a yield of 85%, melting point 115-117°C.

[0010] Add 68ml of water and 23ml of concentrated sulfuric acid into a 500ml three-necked flask, and when the temperature drops to about 70°C, add 12g of 2,5-dimethoxybenzenesulfonyl chloride and 18g of zinc powder, react at 80°C for 1 hour, filter, Under reduced pressure and distillation, 8.2 g of 2,5-dimethoxythiophenol was obtained.

[0011] Add 3g of potassium hydroxide and 50ml of absolute ethanol into a 250ml three-necked flask, stir to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com