Preparation method of 4-methoxy-beta-phenylethylamine

A technology of methoxybenzaldehyde and methoxy, which is applied in the field of preparation of 4-methoxy-β-phenethylamine, can solve the problems of cumbersome reaction steps, low reaction yield, difficult industrialization and the like, and achieves reactivity High, simple operation steps, short response time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

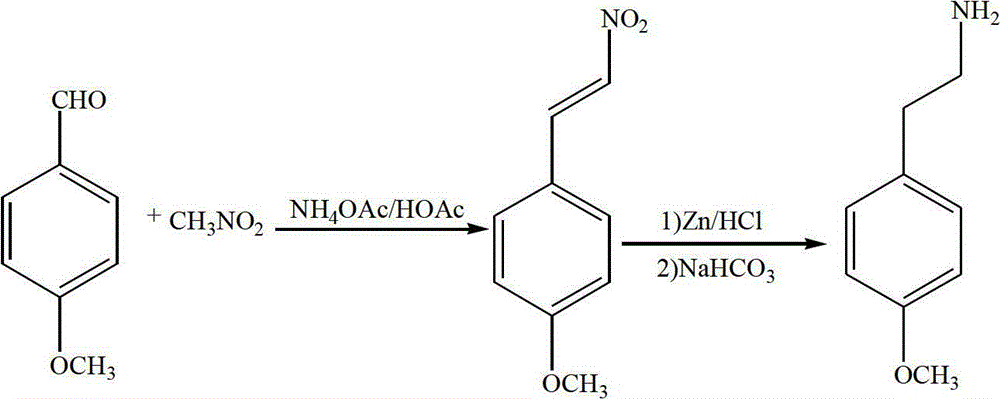

[0017] 1) Preparation of 4-methoxy-β-nitrostyrene

[0018] In the reactor, add 20.4g (0.15mol) 4-methoxybenzaldehyde, 20.1g (0.33mol) nitromethane, 14.0g (0.18mol) ammonium acetate and 75ml (1.3mol) glacial acetic acid, stir and heat to reflux, After reacting for 4~4.5h, the reaction solution was cooled to 12~15°C, then poured into ice water at -2~2°C, yellow needle-like crystals were precipitated, filtered with suction, the filter cake was washed with water, and dried to obtain 4-methoxy- β-nitrostyrene is a yellow solid, and then recrystallized with tetrahydrofuran alcohol to obtain 23.5 g of yellow crystals, yield: 87.3%, m.p.: 85~87 °C;

[0019] 2) Preparation of 4-methoxy-β-phenethylammonium

[0020] Add 64.9g (1.0mol) of zinc powder into the reaction, then add 10~30Wt.% hydrochloric acid aqueous solution, the amount added is less than the zinc powder, stir evenly, let stand for 0.5~1h, filter to obtain activated zinc powder;

[0021] In the reactor, add activated zinc ...

Embodiment 2

[0023] 1) Preparation of 4-methoxy-β-nitrostyrene

[0024] In the reactor, add 20.4g (0.15mol) 4-methoxybenzaldehyde, 24.7g (0.45mol) nitromethane, 16.4g (0.21mol) ammonium acetate and 82ml (1.4mol) glacial acetic acid, stir and heat to reflux, After reacting for 4~4.5h, the reaction solution was cooled to 10~15°C, then poured into ice water at -2~2°C, yellow needle-like crystals were precipitated, filtered with suction, the filter cake was washed with water, and dried to obtain 4-methoxy- β-Nitrostyrene is a yellow solid, and then recrystallized from tetrahydrofuran alcohol to obtain 23.8g of yellow crystals, yield: 88.5%, m.p.: 85~87°C;

[0025] 2) Preparation of 4-methoxy-β-phenethylammonium

[0026] Add 54.5g (0.84mol) of zinc powder into the reaction, then add 10~30Wt.% hydrochloric acid aqueous solution, the amount added is less than the zinc powder, stir evenly, let stand for 1h, and filter to obtain activated zinc powder;

[0027] In the reactor, add activated zinc p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com