High-selectivity (E)-beta-nitrostyrene derivative one-pot synthesizing method

A technology of styrene derivatives and nitrostyrene, applied in the direction of preparation of nitro compounds, chemical instruments and methods, organic compounds/hydrides/coordination complex catalysts, etc., can solve difficult industrial applications, environmental and human hazards Large size, low reaction efficiency and other problems, to achieve the effect of facilitating industrial production, easy separation and purification, and simplified process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~15

[0046] Embodiment 1~15 all reacts by following reaction equation:

[0047]

[0048] The specific operation steps are: alkene (0.5mmol), NH 4 I (1.5 equivalents, 0.75mmol, 108mg), TBHP (70% H 2 O, 6.0 equiv, 3.0 mmol, 384 mg), TPPFeCl (3-5% on molar styrene) and acetonitrile (2 mL) were added to a sealed tube. Acetonitrile was added first, followed by olefin, NH 4 I and TPPFeCl, and finally TBHP. The reaction was stirred vigorously at 120 °C for 6 hours and monitored by TLC. After the reaction was complete, the mixture was cooled to room temperature, then filtered and washed with ethyl acetate (EA). Finally, the filtrate was concentrated with a rotary evaporator, and purified by column chromatography with silica gel (200-300 mesh) using petroleum ether (PE) / ethyl acetate (EA) as eluent.

Embodiment 1

[0050] Olefins: Target product:

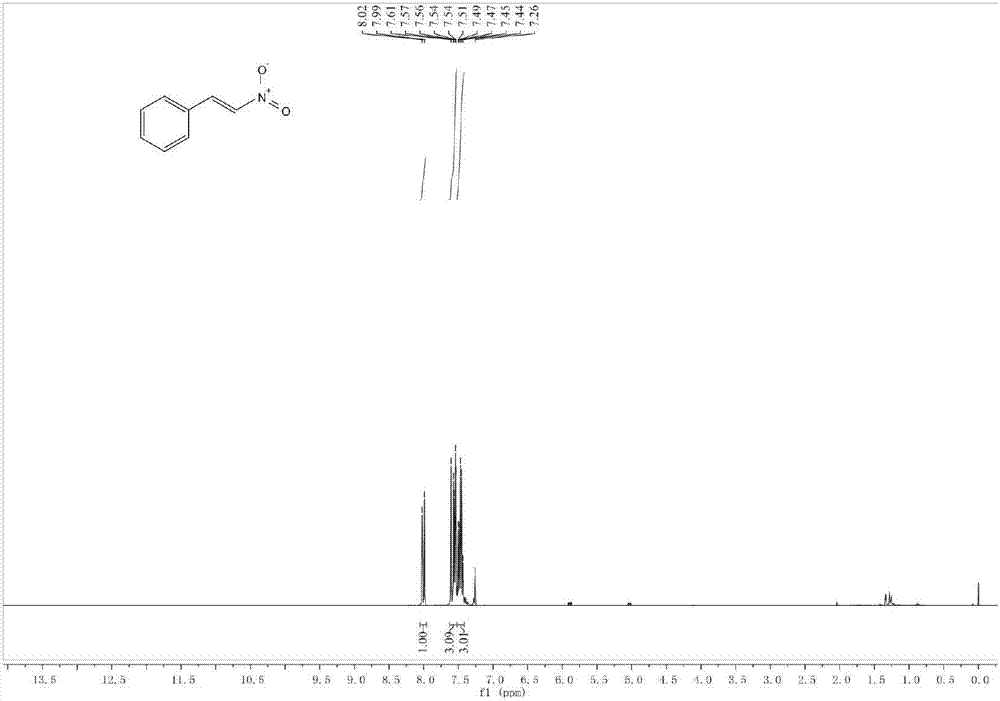

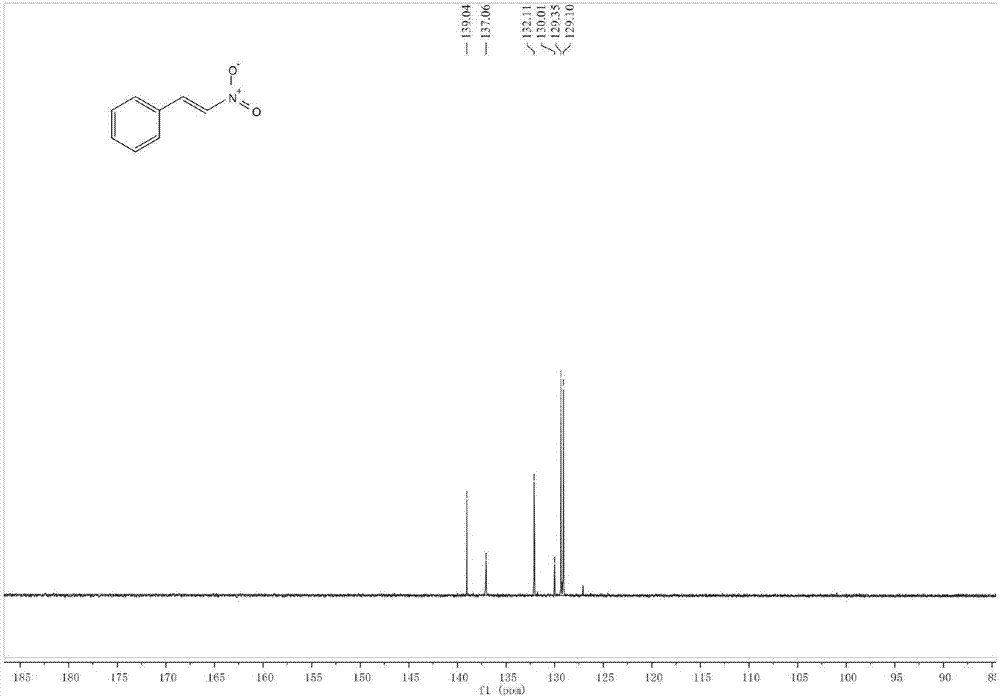

[0051] Yellow solid: 82% (61mg). 1 H NMR (400MHz, CDCl 3 )δ8.01(d, J=13.7Hz, 1H), 7.63–7.53(m, 3H), 7.47(tdd, J=8.5, 5.2, 3.6Hz, 3H). 13 C NMR (101MHz, CDCl 3 )δ139.04,137.06,132.11,130.01,129.35,129.10.GC-MS(m / z):149.+.

Embodiment 2

[0053] Olefins: Target product:

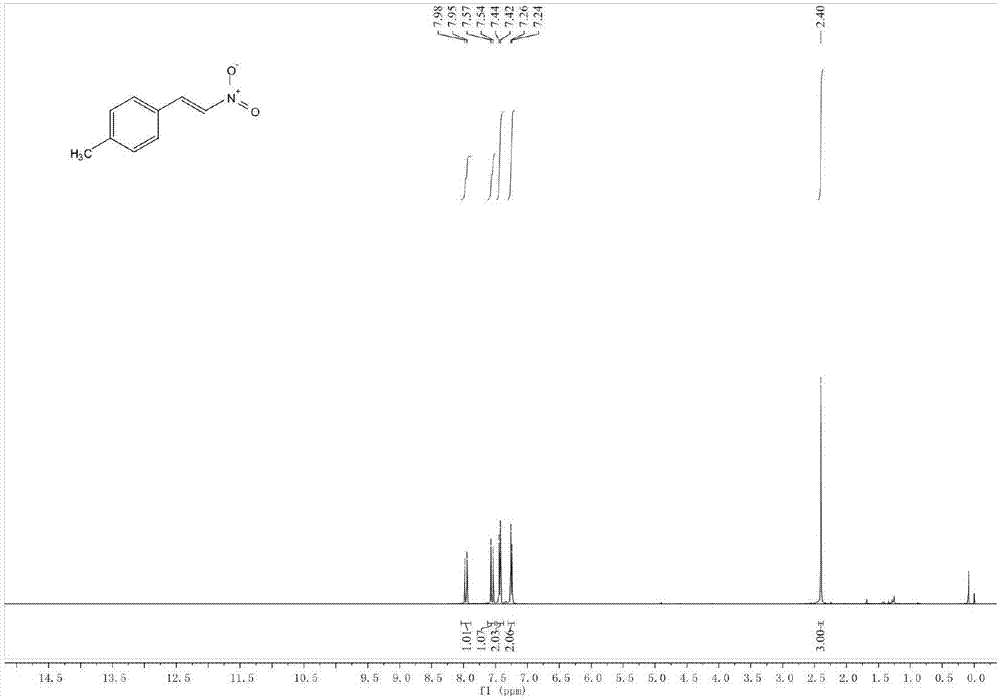

[0054] Yellow solid: 77% (63mg). 1 H NMR (400MHz, CDCl 3 )δ7.96(d, J=13.6Hz, 1H), 7.55(d, J=13.6Hz, 1H), 7.43(d, J=8.1Hz, 2H), 7.25(d, J=8.2Hz, 2H) ,2.40(s,3H). 13 C NMR (101MHz, CDCl 3 )δ143.04, 139.08, 136.17, 130.06, 129.12, 127.17, 21.56. GC-MS (m / z): 163.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com