Practical assembling method for microcylinder lens and optical fibre

A technology of micro-cylindrical lens and assembly method, which is applied in the coupling of optical waveguides and other directions, and can solve problems such as large optical power coupling loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] For the difficulties faced in the above several situations, an effective solution is to process a micro-lens of a certain shape on the end of the optical fiber. The micro-lens makes the mode field of the semiconductor laser match the mode field of the optical fiber, so that we can obtain Satisfactory coupling efficiency.

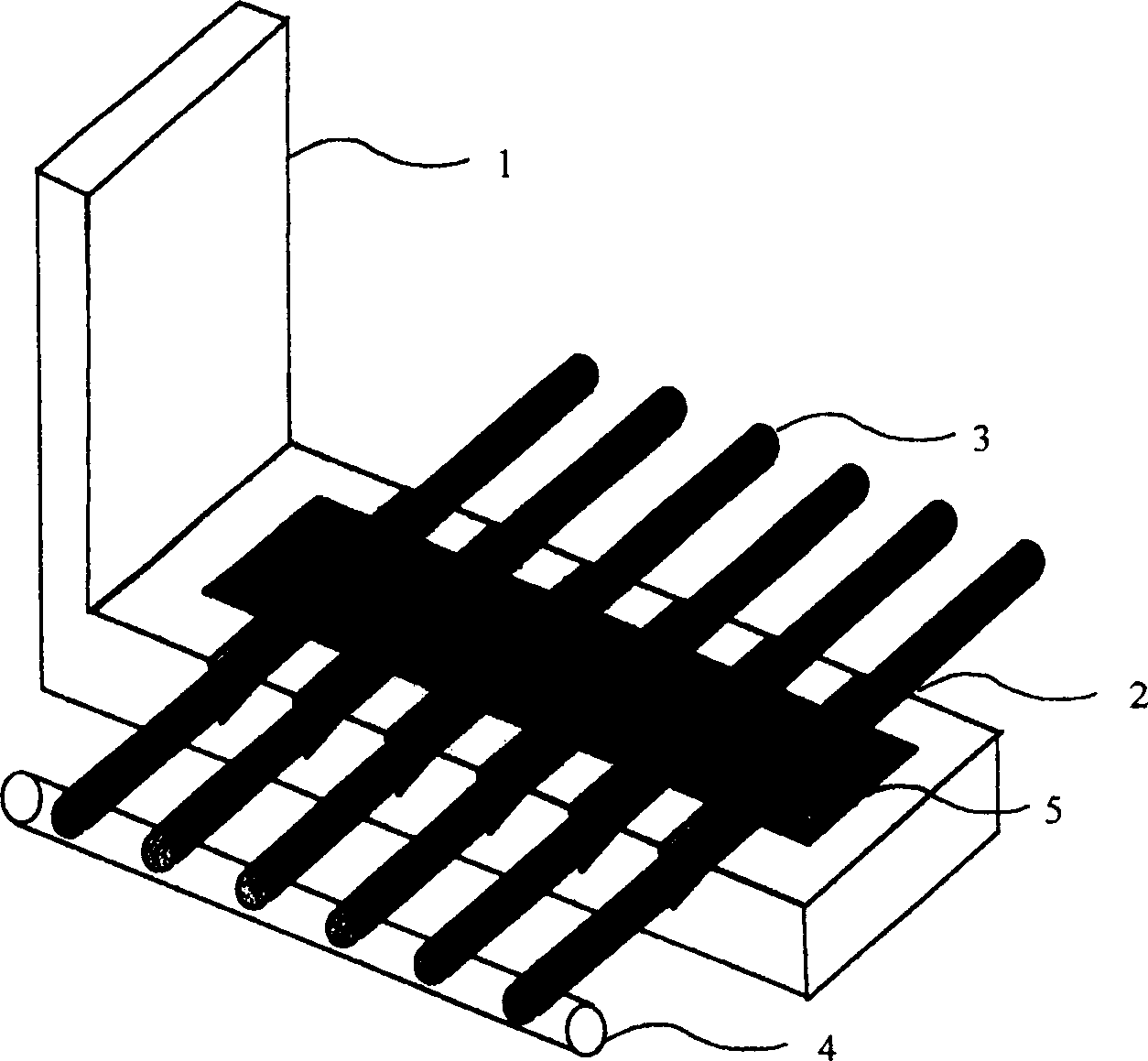

[0021] First, use a fiber cleaver to cut out an optical fiber with a flat end surface and a mirror surface for future use. exist figure 1 On the L-shaped bracket 1 shown, equidistant V-shaped grooves 2 are engraved by precision machining. The distance between the V-shaped grooves 2 should be equal to the distance between the semiconductor laser array light-emitting units to be coupled with it. The number of 2 is at least two more than the total number of light emitting units of the semiconductor laser array. After the V-shaped groove 2 is engraved, insert the cut optical fibers into the V-shaped groove 2 one by one, cover the top with a cover plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com