Method and device for pickling hot-rolled special steel strips

A technology for hot-rolled strips and special steels, applied in metal rolling, metal rolling, workpiece surface treatment equipment, etc., can solve the problems of reducing strip quality and high work costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

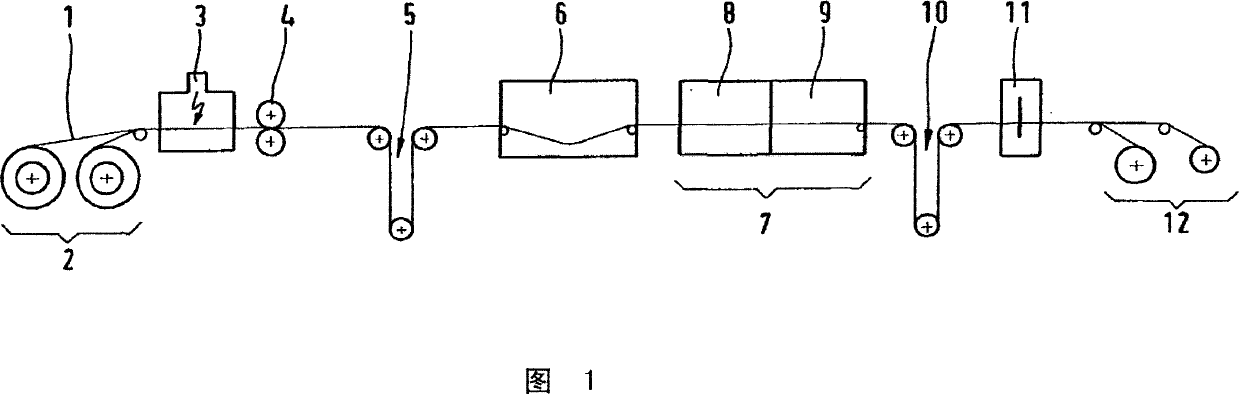

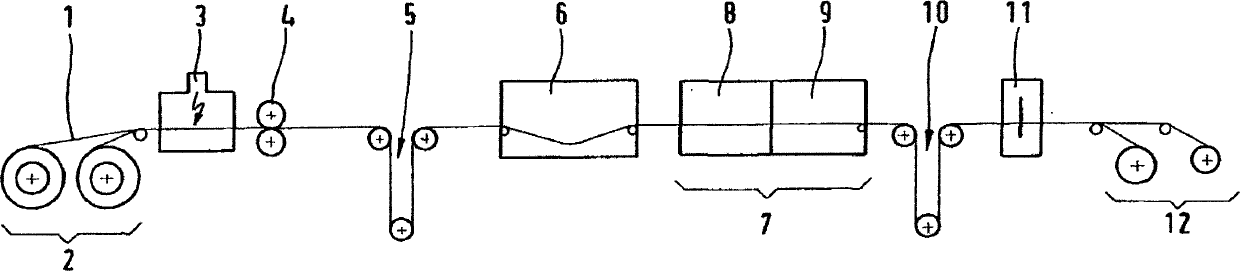

[0018] According to Fig. 1, the hot-rolled strip 1 of special steel is passed from the coil of the inlet section 2 through the welding device 3 (for coil change), an edge trimmer 4 into an inlet looper pick 5 and, if necessary, further A softening annealing furnace 6 ground into the pickling line. The pickling stage 8 and the rinsing stage 9 constitute the pickling operation line 7, and the pickling stage and the rinsing stage will be described in detail below. The hot-rolled strip 1 of special steel emerges from the final rinsing stage 9 and enters an exit looper 10 and the strip ends through an exit shear 11 . During continuous operation, the hot-rolled strip of special steel is recoiled into coils at the export stage.

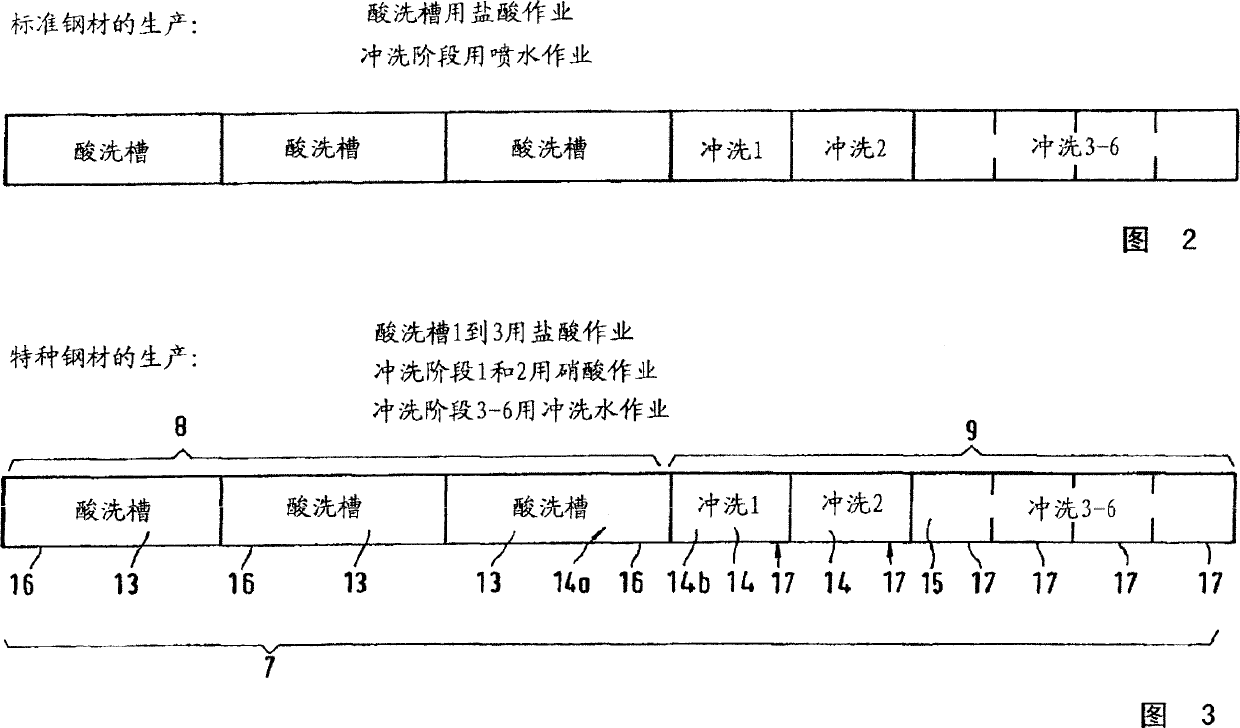

[0019] According to Fig. 2, in the production of standard steel products, the pickling line 7 works with three pickling tanks and hydrochloric acid in the pickling stage 8, and at the same time, all the flushing stages work with flushing water (No. , 3-6 w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com