Locating method for large size work pieces in machine work

A large workpiece, machining technology, applied in metal processing, metal processing equipment, metal processing mechanical parts, etc., can solve problems such as inability to use, measurement of workpiece positioning information, and inconvenience in cutting and processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

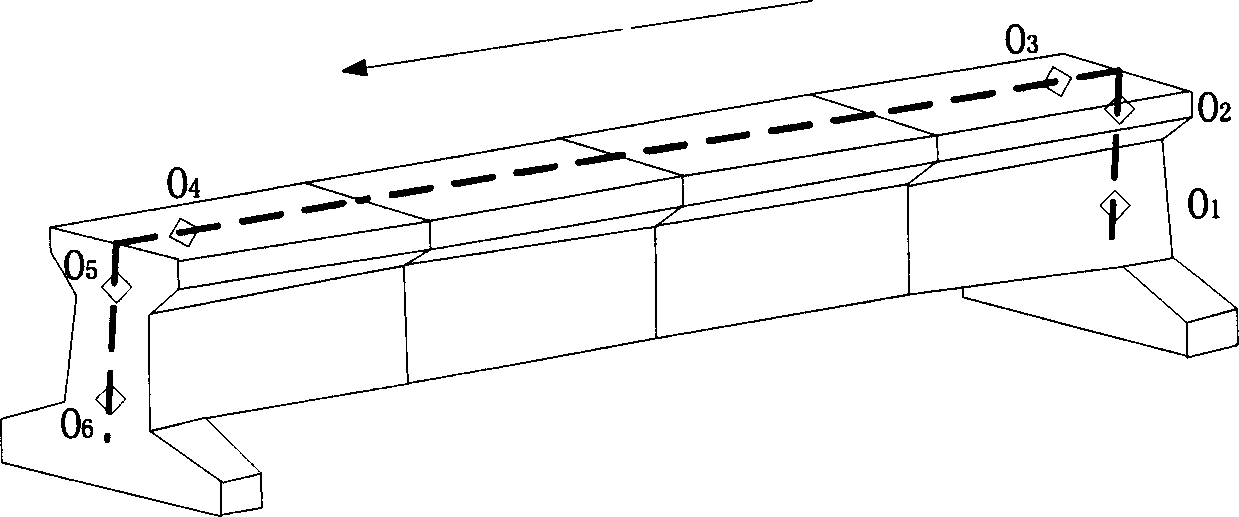

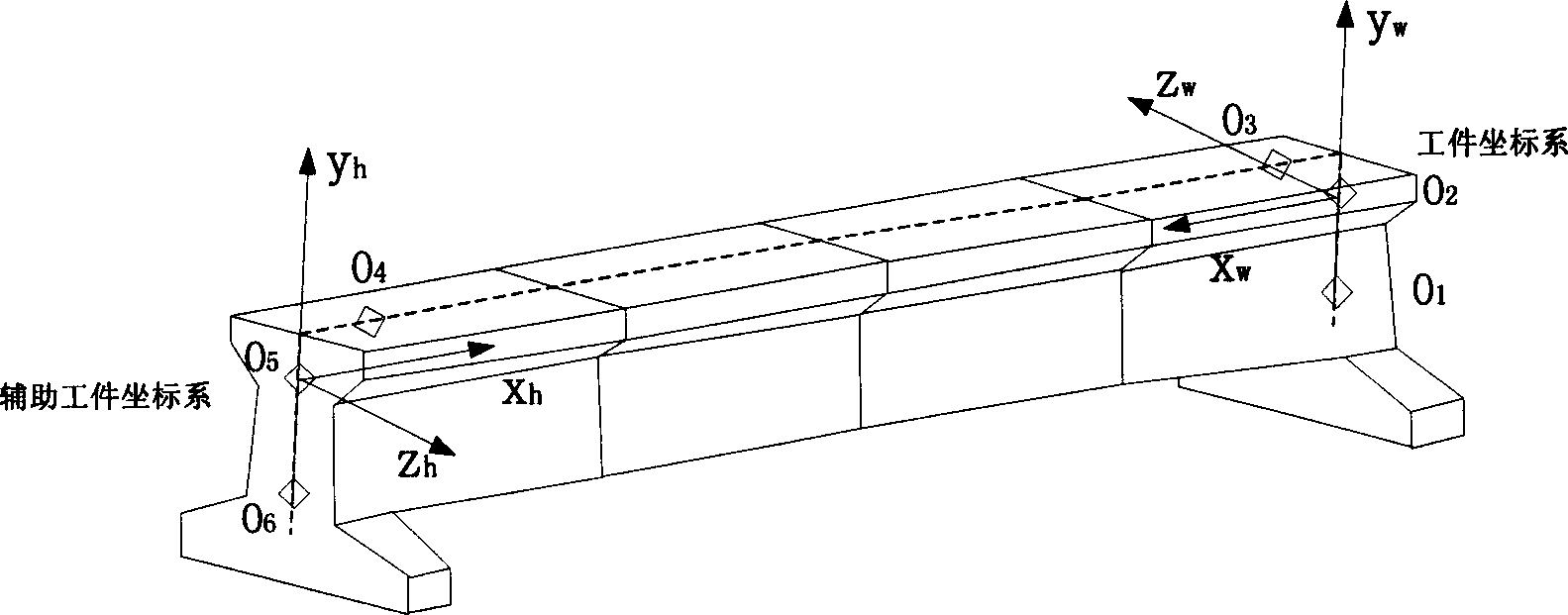

[0111] Example: The present invention is applied to the processing of rail beams of Shanghai maglev train. The layout of the processing system is as follows Figure 4 As shown, the two machine tools are five-axis machine tools, the workpiece is located in the middle of the two machine tools, the machine tool X-direction travel is about 30 meters, the full closed-loop control of the grating ruler is adopted, the machine tool column can rotate around the Y axis, and the spindle rotates around the X axis. The relationship between the coordinate systems of the two machine tools is known, and the coordinates of the midpoint of any machine tool can be easily translated to another machine tool.

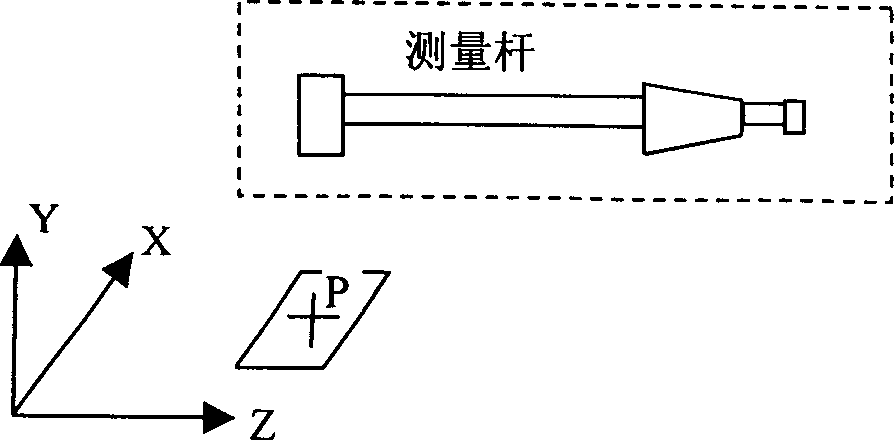

[0112] Measure by using a sight. The sight is a non-contact measuring device, which measures six points on the workpiece using the workpiece positioning information obtained by the calculation method of the present invention, and then compiles the corresponding processing program, and the CNC mac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com