Redundant driving parallel device for machine tool

A new type of parallel technology, applied in the direction of large fixed members, metal processing machinery parts, metal processing, etc., can solve the problems of small working space of machine tools, small attitude ability and difference in flexibility of machine tool processing tools, etc., to increase the working space And the effect of corner ability, simple structure and large working space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

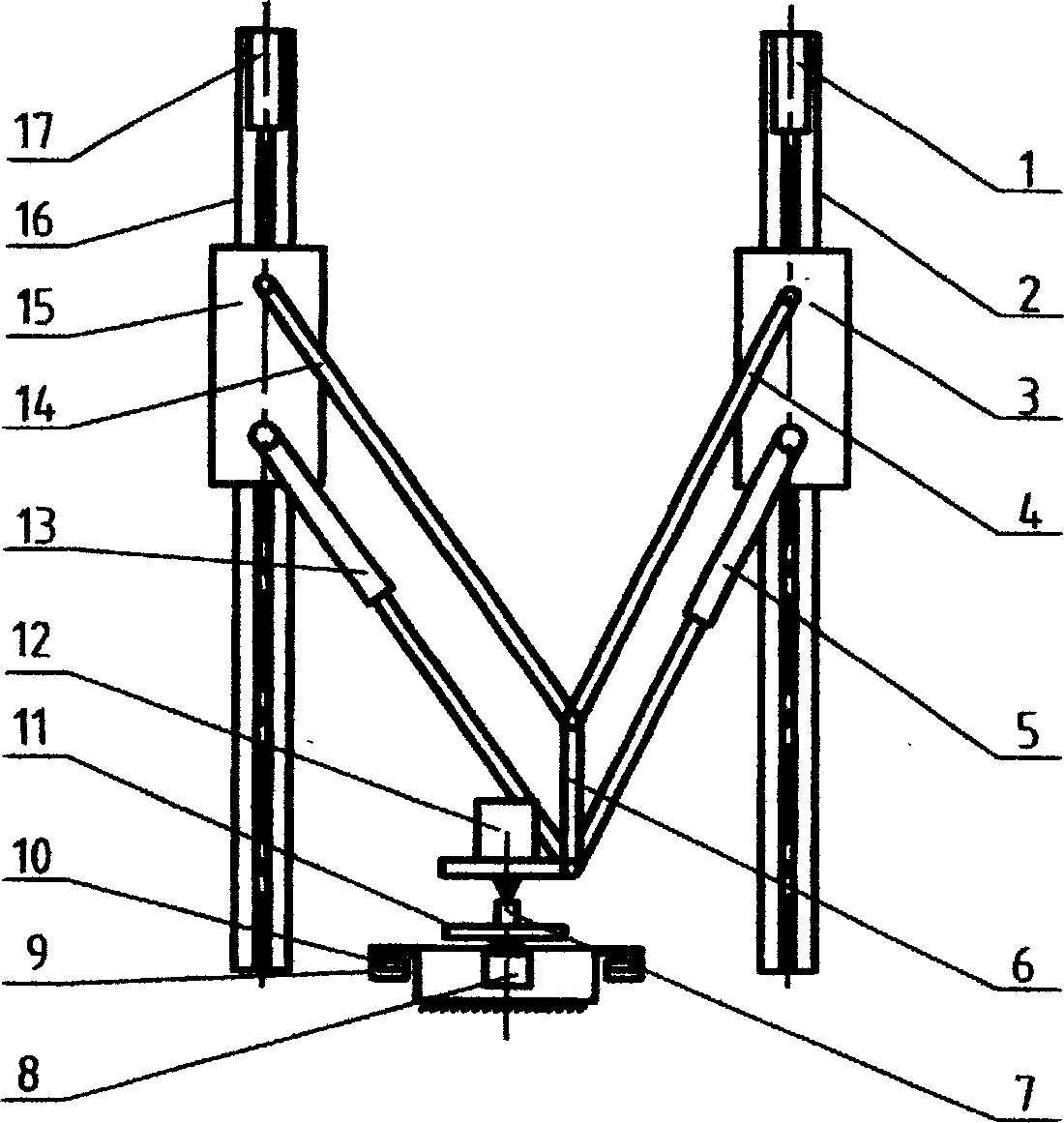

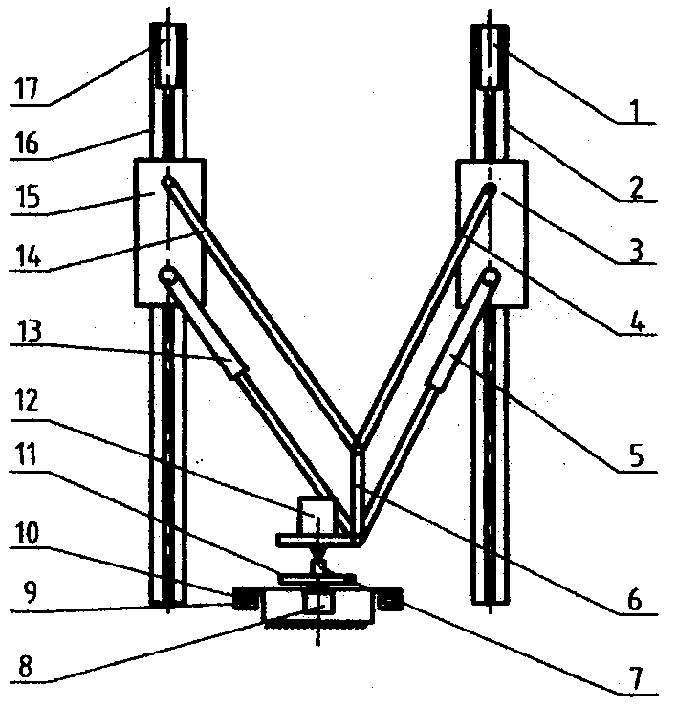

[0010] figure 1 Shown is a structural schematic diagram of a novel redundant drive parallel device of a machine tool. The structure of the redundant drive parallel device of the machine tool of the present invention is that one end of the two drive rods 4, 14 is hinged together, and the other ends are respectively connected to Controllable slide block 3,15 is connected; Controllable slide block 3,15 is respectively fixed with one end of two controllable telescopic shafts 5,13, and the other end of two controllable telescopic shafts 5,13 is connected with said One end of the moving platform 6 is connected at the same position, and the other end of the moving platform 6 is connected with the hinge points of the two drive rods 4, 14 to form a plane parallel closed-chain mechanism.

[0011] Its working principle is to form the planar parallel closed-chain structure by driving rod 4,14, controllable telescopic shaft 5,13, moving platform 6, slide block 3,15, guide rail 2,16. W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com