Industrial preparation process for perfluorotributylamine

A technology of perfluorotributylamine and tributylamine, which is applied in the direction of electrolysis process, electrolysis components, electrolysis organic production, etc., can solve the problem of not researching the preparation process and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

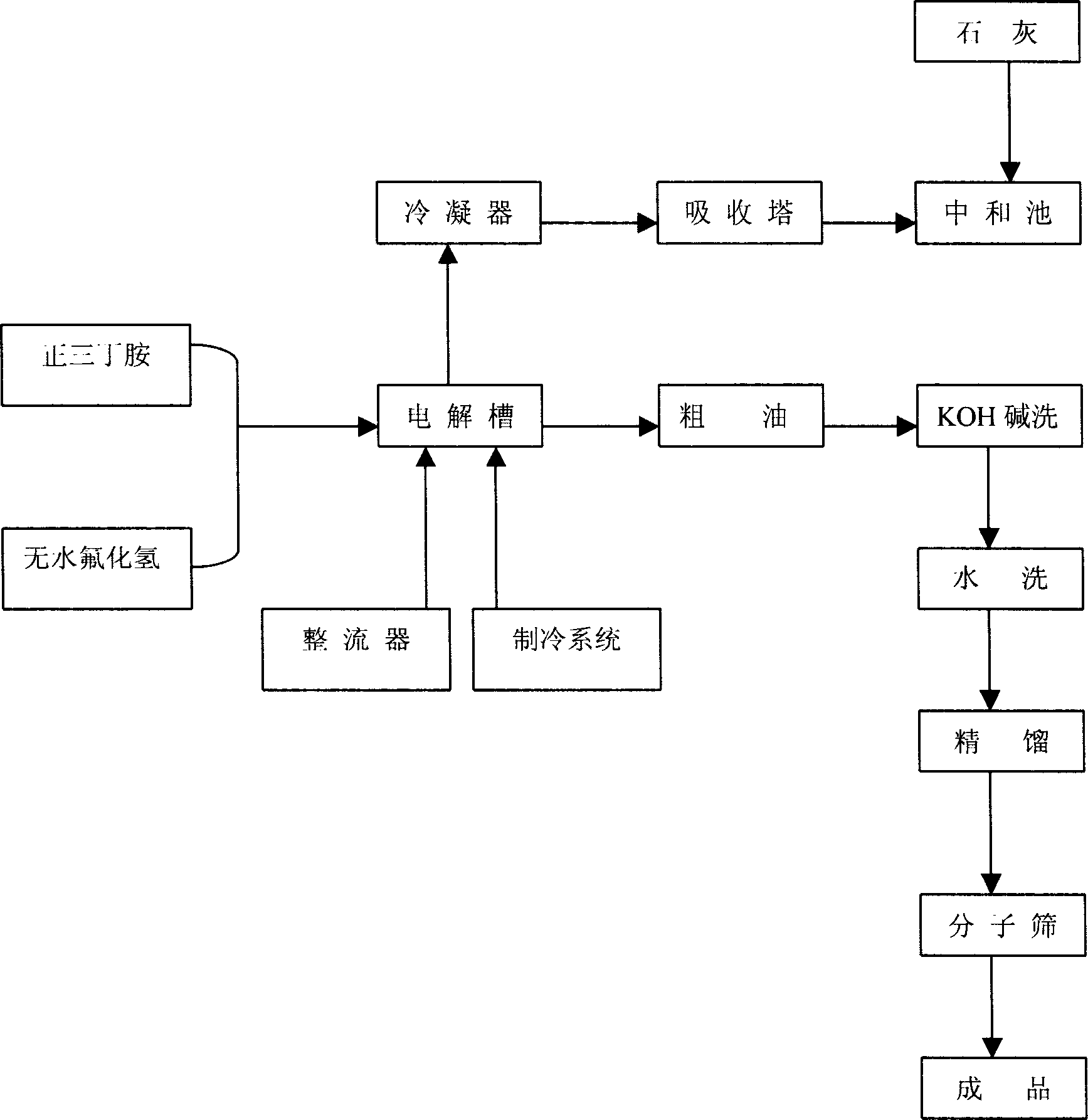

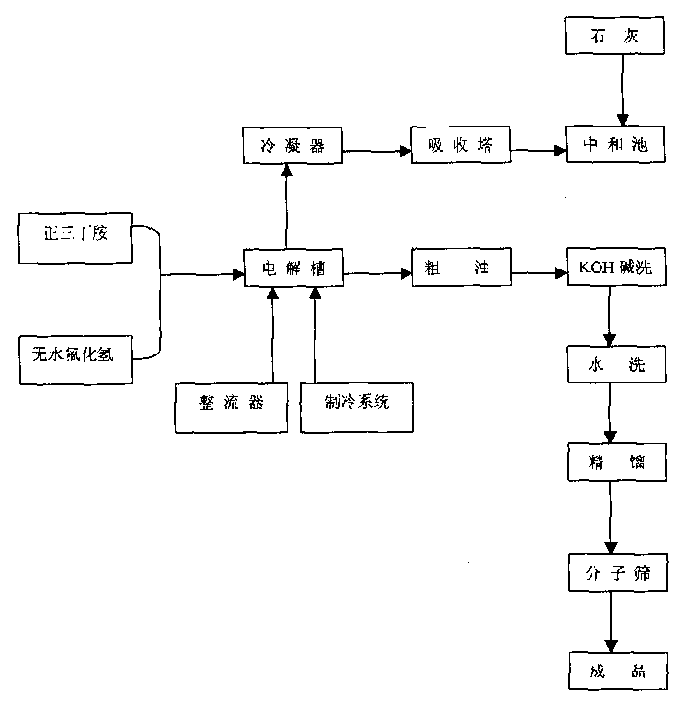

[0019] The technological process of the industrialized preparation method of perfluorotributylamine of the present invention is as attached figure 1 As shown, the main control parameters of the electrolytic cell are: voltage between electrodes: 5.0~7.0V; electrolysis current: 0~2500A; electrolysis temperature: -1~5℃; condensation area of the condenser is 10 square meters; The rectification specification is 3000A; the specification of the refrigerating unit is LG12.5, and the present invention includes the following steps: (1), hydrogen fluoride electrolytic dehydration:

[0020] Press hydrogen fluoride into the electrolytic cell with nitrogen, control the temperature of the electrolytic cell between -1 and 5°C through the refrigeration system, and supply direct current to the electrolytic cell through the rectifier, the voltage is 5 to 7V, and the current is 0 to 2500A. Adjust the input voltage of the electrolyzer and control the voltage between 5.2V. At this time, hydrogen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com