Drastic desulfurizing method for light end products by solid base

A light oil product, deep desulfurization technology, applied in the direction of refining with solid alkaline materials, etc., can solve the adverse effects of the operation cycle of the deodorization device in the subsequent step, environmental pollution, unfavorable problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

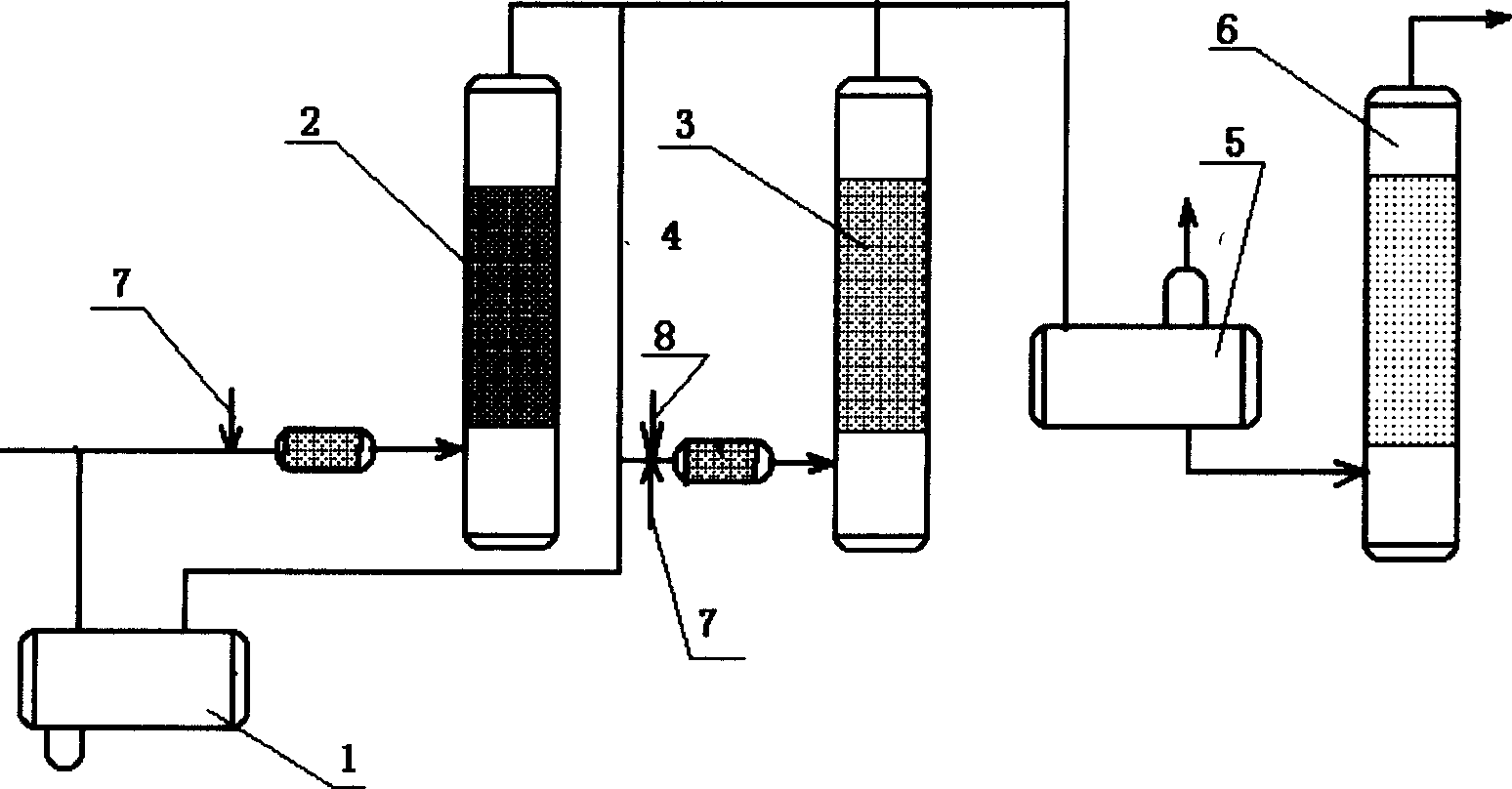

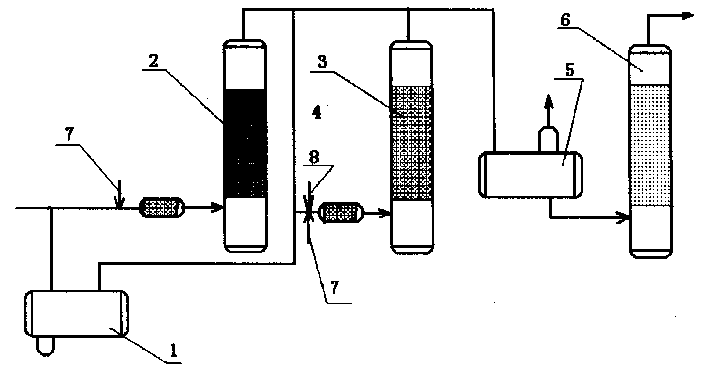

[0012] The technical characteristics of the present invention will be described in detail below in conjunction with the embodiments.

[0013] In actual design and implementation, the designer realizes the technique described in the present invention in the following manner:

[0014] 1. After alkali washing (liquid alkali washing or solid alkali washing), the gasoline enters the oxidation deodorization tower for sweetening. The sweetened gasoline is directly fed into the liquid separation tank, and the separated gasoline is sent to the sand filter tower in the next step.

[0015] 2. In the process, another process is that if the gasoline is washed with solid alkali, it can meet the mercaptan sulfur content index requirements, and the gasoline can be directly discharged from the solid alkali tower to the gas-liquid separation tank without further demercaptan treatment. The separated gasoline goes to the sand filter tower in the next step.

[0016] 3. Gasoline alkali washing can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com