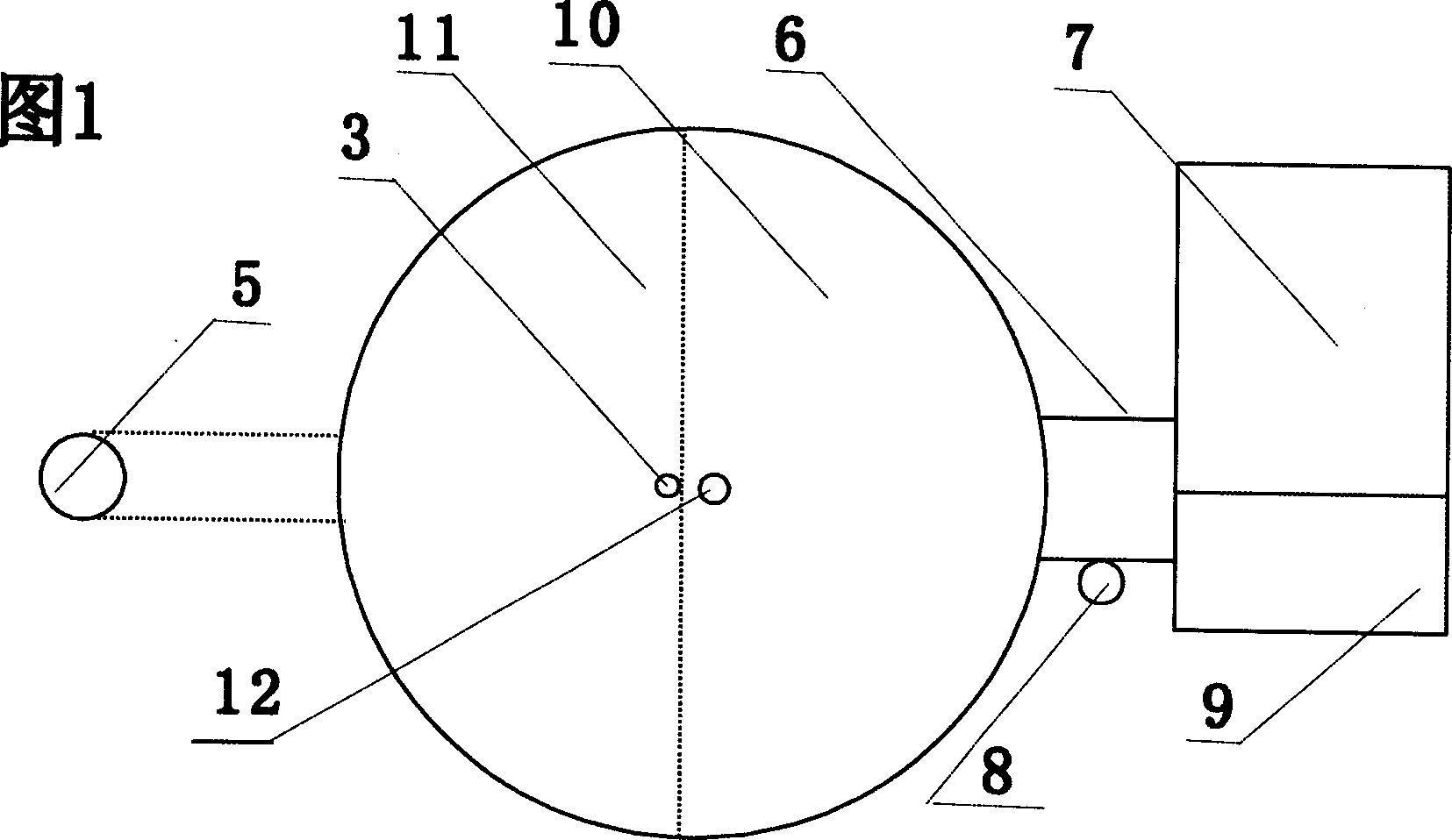

Combined equipment for producing storing and using methane

A storage device and biogas technology, applied in the direction of gas production bioreactors, biochemical instruments, biochemical equipment and methods, etc., can solve the problems of inconvenient use and management by farmers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

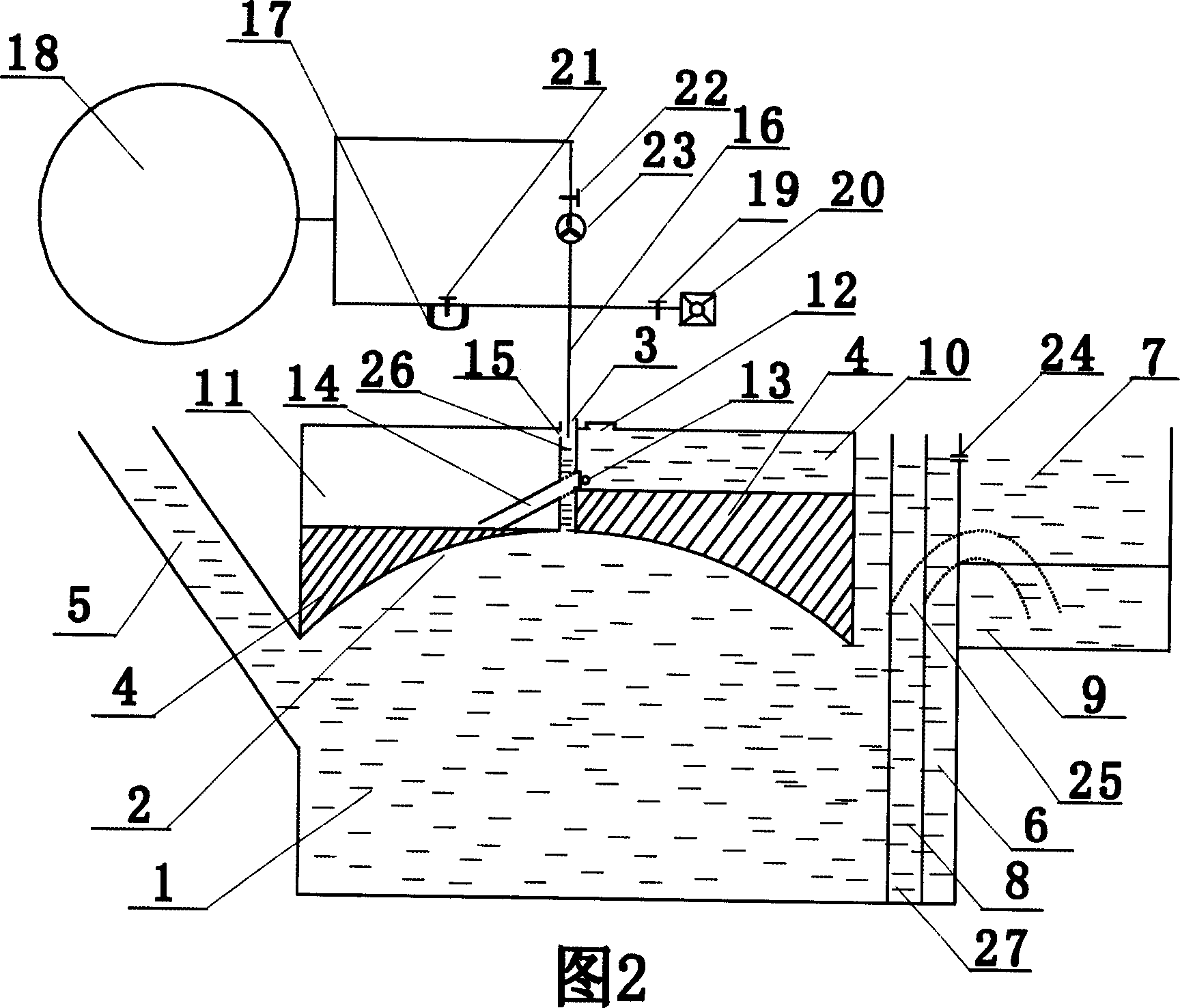

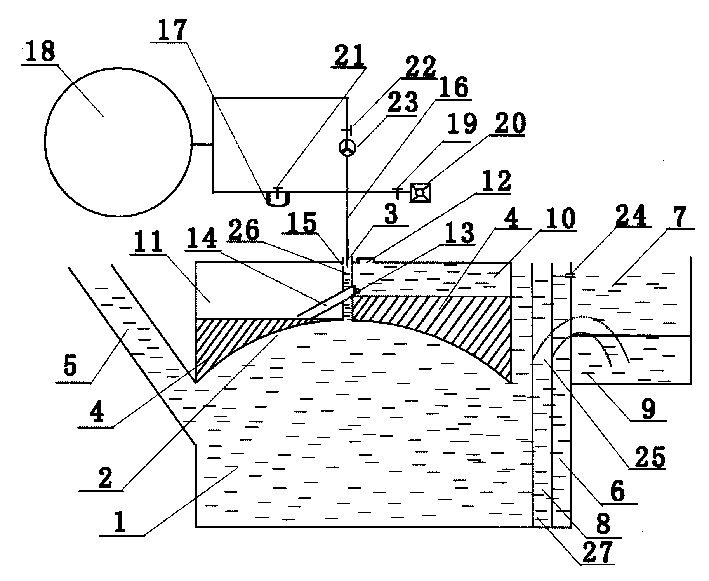

Embodiment Construction

[0021] In a specific embodiment of the present invention, the feeding pipe 5 is connected to the sewage ditch, and the biogas digester is connected to the pigsty, toilet, etc., water and organic matter enter the fermentation tank 1 through the feeding pipe 5, and are fermented and decomposed in the airtight container 1 To produce biogas, the fermentation tank 1 is fully loaded for fermentation, and the scum is pressed into the water under the arch cover 2, which can be completely decomposed and fermented without scum crusting, and the produced biogas naturally floats up and accumulates in the arch cover 2 Under the top of the exhaust pipe 3, the biogas naturally overflows out of the pool through the exhaust pipe 3. Under the blockage of the valves 19, 21, 22 and the adjustable pressure limiting valve 17, the biogas passes through the upper part of the exhaust pipe 3. Another discharge port 15 of the airtight air storage chamber 11 is discharged into, and the water liquid flowin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com