Seat for vehicle and method for manufacture thereof

A manufacturing method and vehicle technology, applied in the direction of vehicle seats, vehicle parts, special positions of vehicles, etc., can solve the problems of affecting the appearance of vehicle seats, difficult to distinguish recycling, unsuitable for recycling, etc., and achieve recycling Superior, light cost, elegant appearance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The invention is explained in more detail here with reference to the drawings.

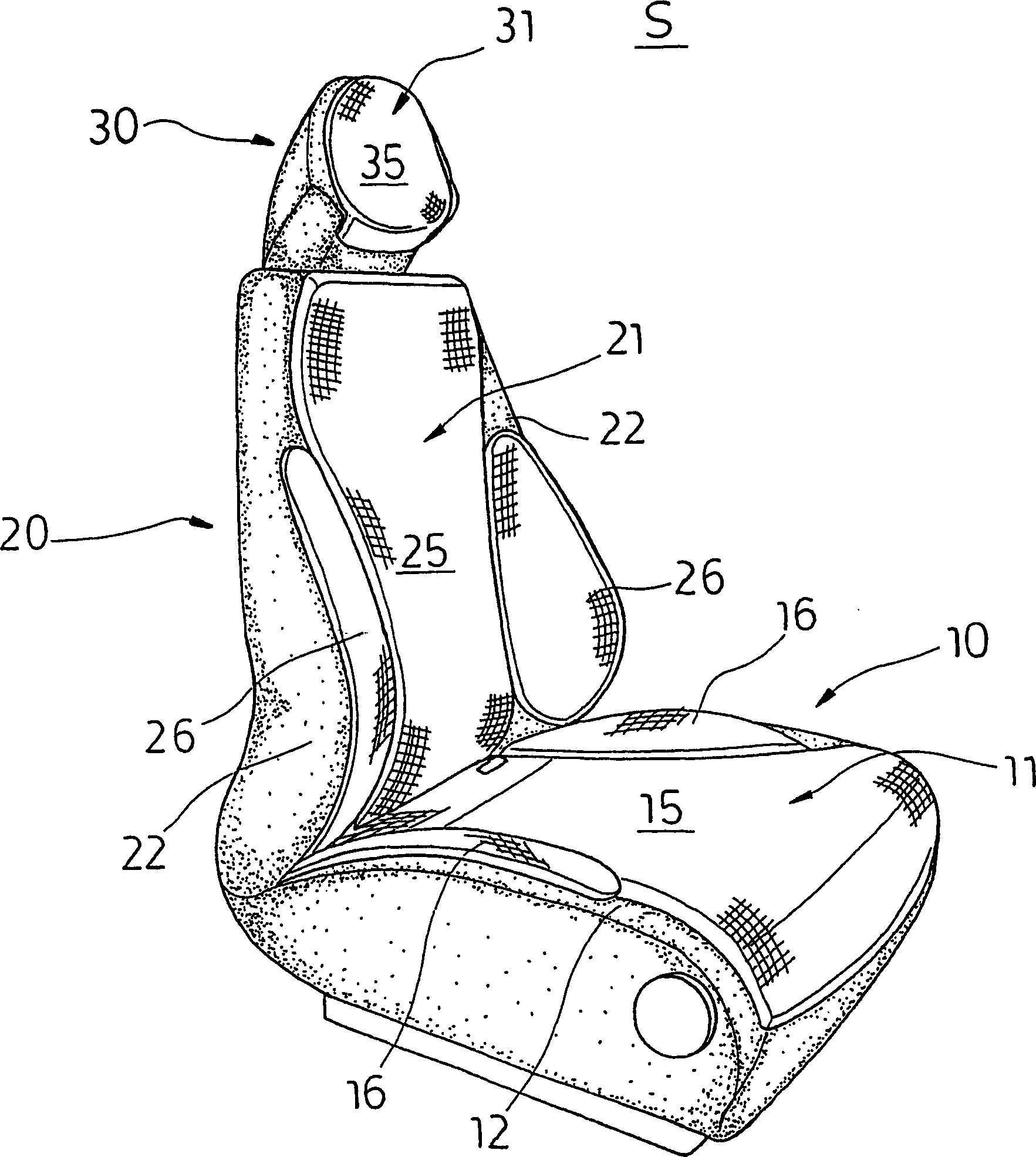

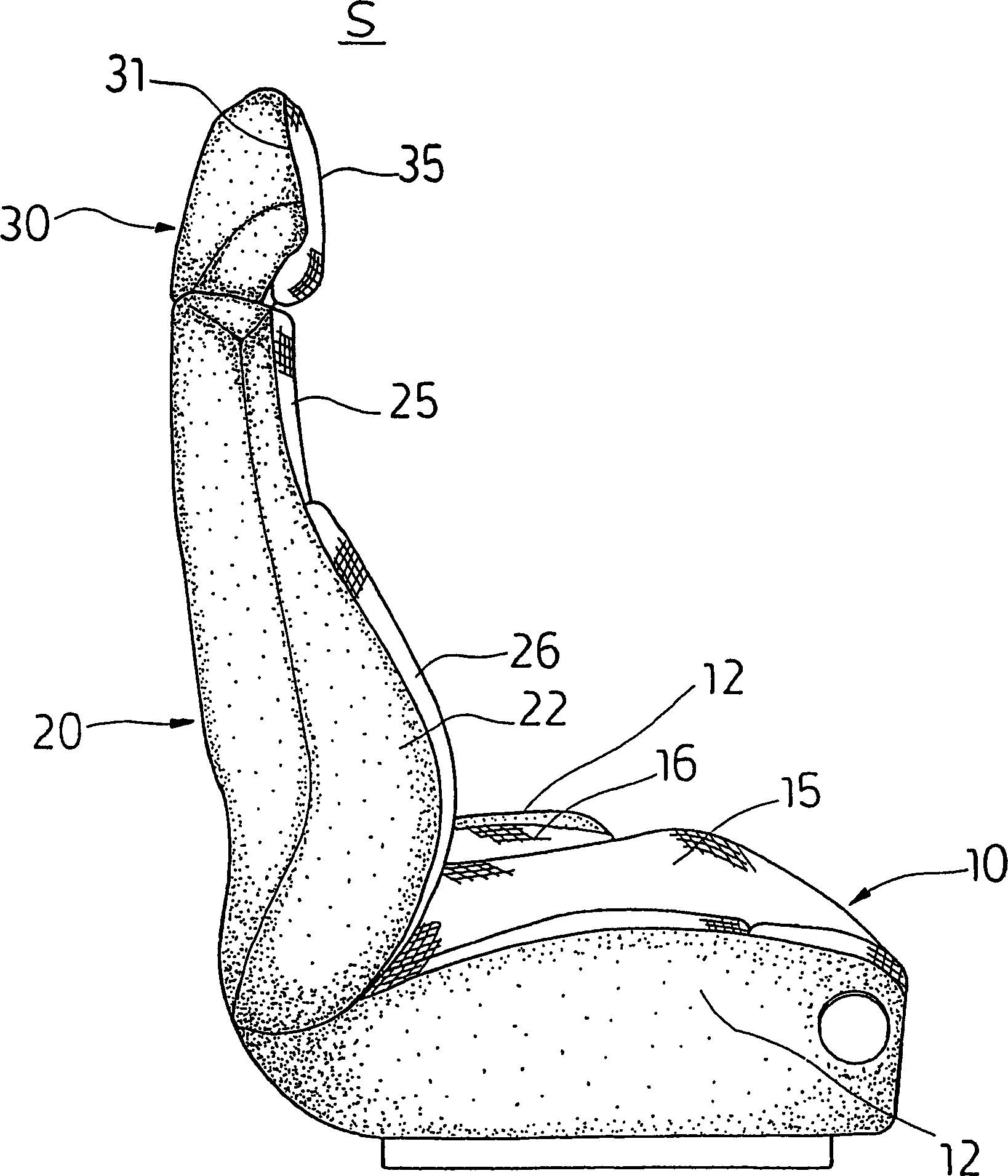

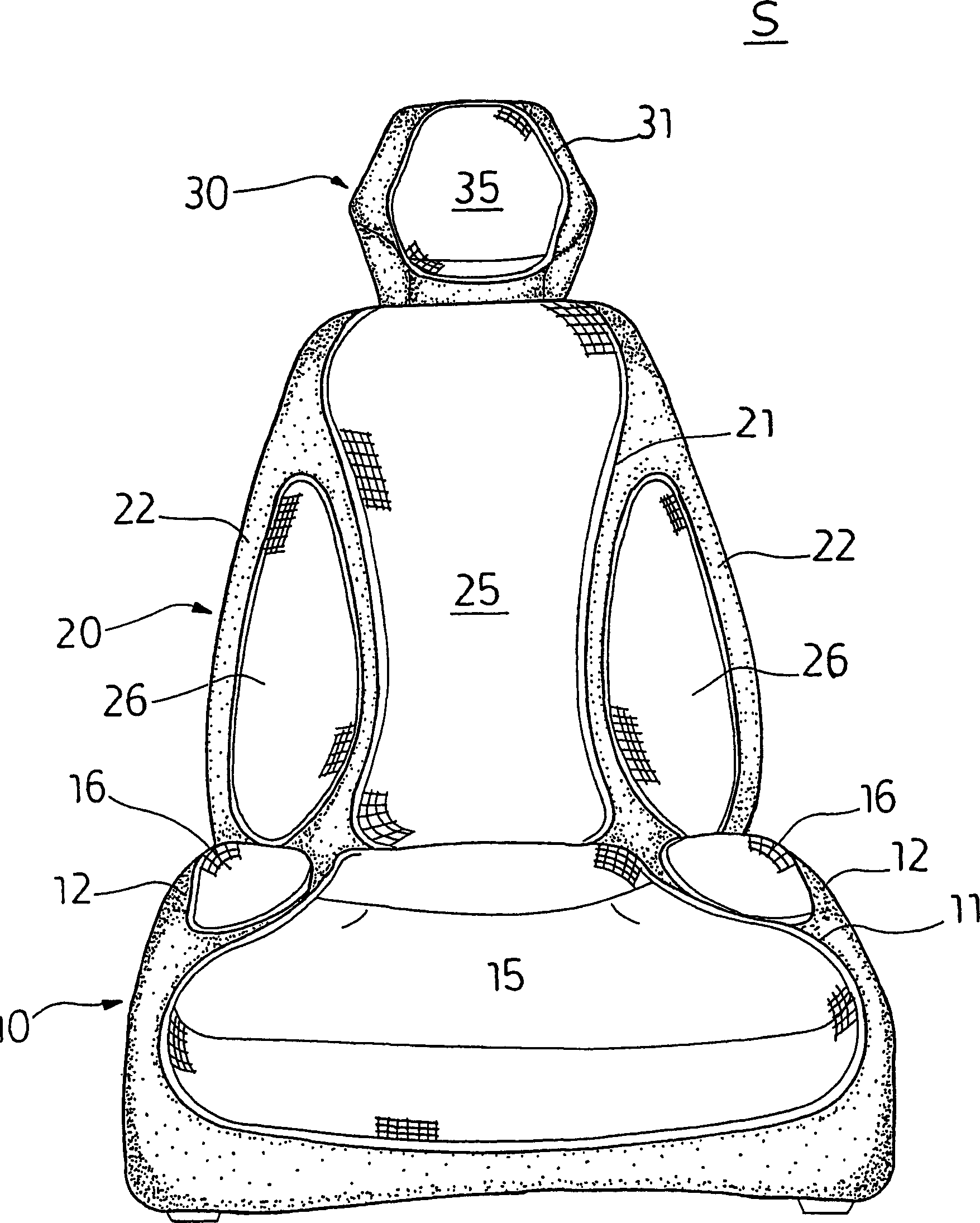

[0040] The vehicle seat S of the present invention may only have the seat portion 10, and as figure 1 As shown, the present embodiment has a seat portion 10 and a seat back portion 20 . In this embodiment, the seat portion 10 is formed by a seat area 11, and embankment portions 12 for fixing are provided on both sides. In addition, the seat back 20 of the present embodiment is formed by the seat back region 21, and the both sides of the seat back region 21 are provided with side pads 22 for ensuring a fixed feeling of the body. Head rest 30.

[0041]In this embodiment, the seat portion 10 , the seat back portion 20 , and the headrest 30 are formed by foam as an exterior decoration material. And, the seat area 11 and the embankment portion 12 of the seat portion 10, the seat back area 21 and the side pad portion 22 of the seat back 20, and the contact support portion 31 of the headrest 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com