Ink jet device, ink and method of manufacturing electronic component using the device and the ink

The technology of an inkjet device and manufacturing method is applied in the direction of electrical components, conductive materials dispersed in non-conductive inorganic materials, circuits, etc., which can solve the problems of easy clogging of printing heads, easy clogging of printing heads, and inability to use them

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

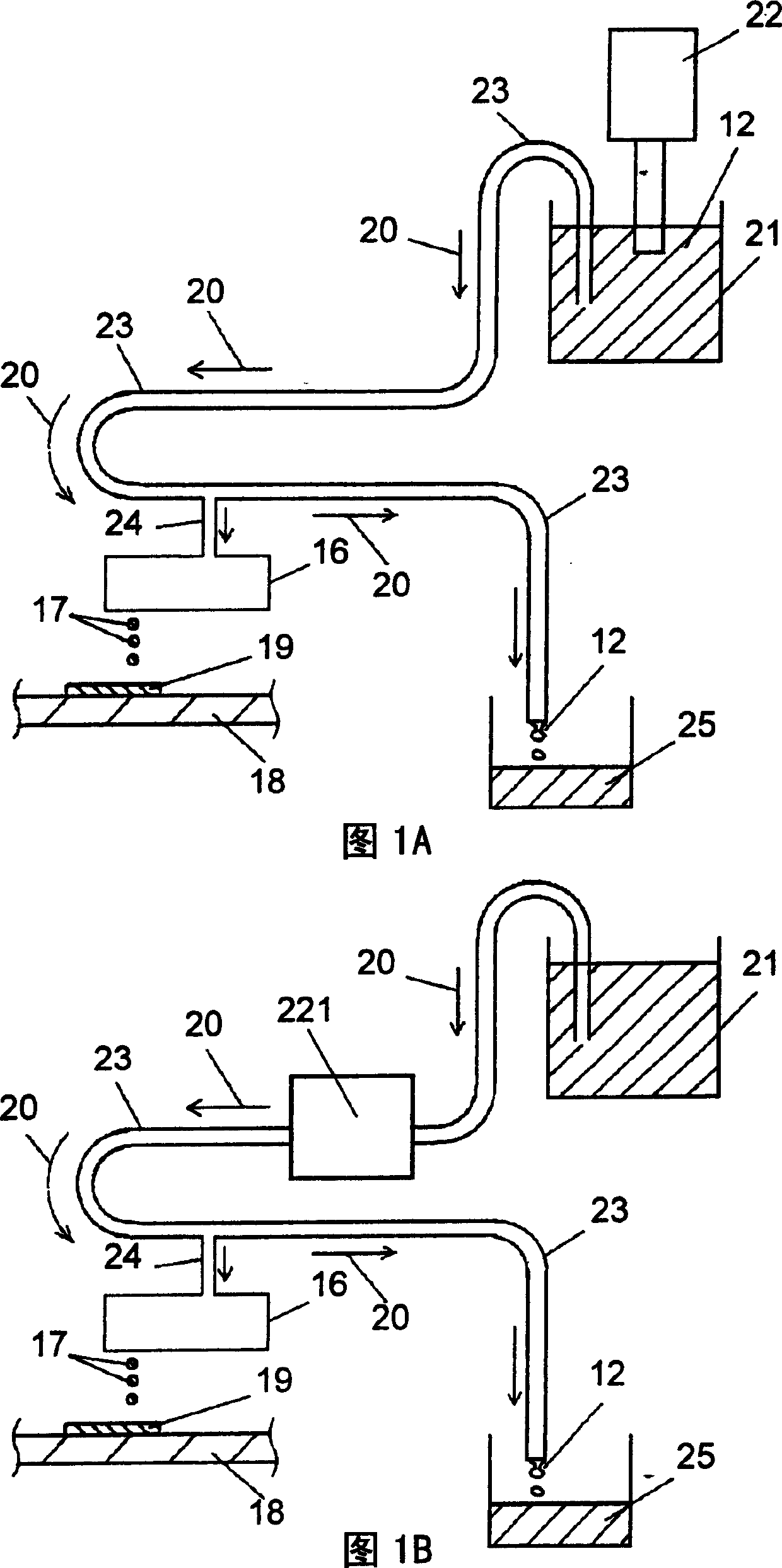

[0041] In Embodiment 1, an ink jet apparatus and an ink supply mechanism thereof according to an embodiment of the present invention will be described with reference to FIG. 1A . In FIG. 1A , the inside of the ink container 21 is filled with the ink 12 . And the disperser 22 re-disperses the ink 12 in the ink container 21 as needed. The ink in the ink container 21 flows into the ink recovery container 25 through the first pipe 23 by its own weight. In addition, by placing the ink container 21 at a position higher than the ink recovery container 25, the siphon principle can be utilized, and it is possible to flow naturally without using a pump or the like. In this way, the ink 12 in the ink container 21 is dropped into the ink recovery container 25 via the first tube 23 . In the present invention, the ink 12 always flows in the first tube 23, and only a required amount is sent to the print head 16 through the second tube 24 during printing. Then, the ink 12 filled in the pri...

Embodiment 2

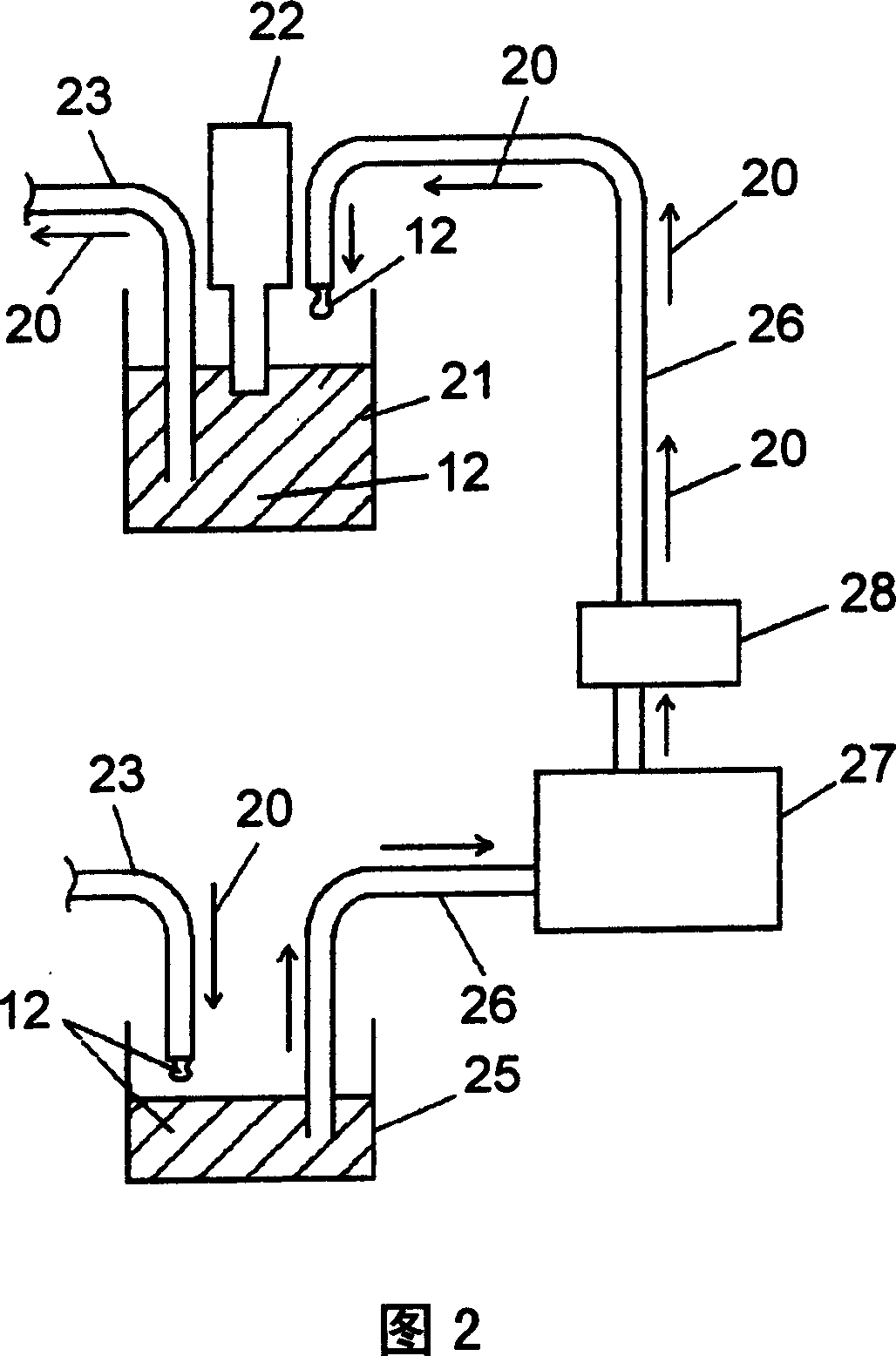

[0053] In Example 2, an example in which printing stability is further improved by removing fine air bubbles mixed into the ink will be described. We know that when a piezoelectric inkjet device is used on the print head 16, tiny air bubbles mixed in the ink will adhere and grow as air bubbles in the printer, absorb the vibration energy of the piezoelectric element, and prevent printing. Stable (for example, it is described in pages 202 to 206 of "Inkjet Printer Technology and Materials" (edited by Professor Takeshi Amari, Chiba University) published by CMC Corporation in 1998). In particular, in the present invention, since the disperser 22 is attached to the ink container 21, depending on the type of the disperser 22 (for example, a high-speed rotary homogenizer, an ultrasonic disperser, etc.), the ink container 21 may be Roll in tiny air bubbles. For example, there are cases in which air bubbles are entangled from the ink surface in a high-speed rotating homogenizer, or mi...

Embodiment 3

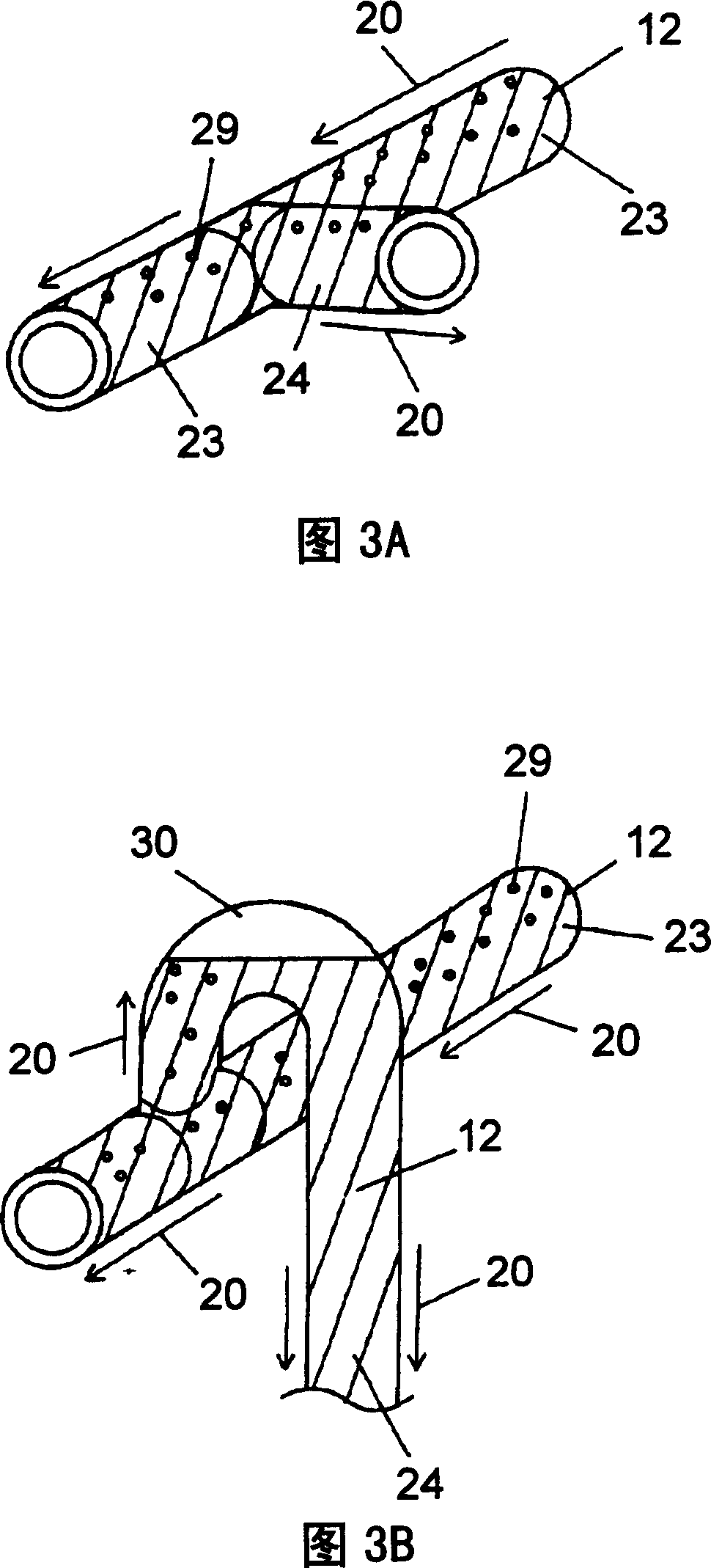

[0063] In Example 3, the characteristic of the present invention, ie, the circulation and dispersion of the ink, will be described in detail. FIGS. 6A and B are examples of actual measurement of the deposition rate of ink for electronic components. In particular, the ink for electronic components is extremely easy to agglomerate as described in FIGS. 16A and B and the like, so it is easy to precipitate. This is explained in further detail using FIGS. 6A and B. FIG. In FIG. 6A , the ink container 21 is filled with the ink 12, and the disperser 22 is immersed in the ink 12 in a state where the switch is OFF. In this way, if the ink is left to stand without using the disperser 22, as shown in FIG. 6A, as the elapsed time increases, a clear layer 36 is formed in the ink 12, and the thickness of the clear layer 36 increases with the elapsed time. FIG. 6B is a diagram illustrating the generation of clear layers of various inks for electronic components. In addition, although a cl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com