Polarization maintaining optical fibre with high birefringence and its manufacturing method

A polarization-maintaining fiber, high birefringence technology, applied in optics, light guides, optical components, etc., can solve the problems of poor process repeatability, high processing cost, fiber strength effect, etc., to overcome complexity and poor process repeatability and simplify manufacturing. Process method, the effect of improving axial uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

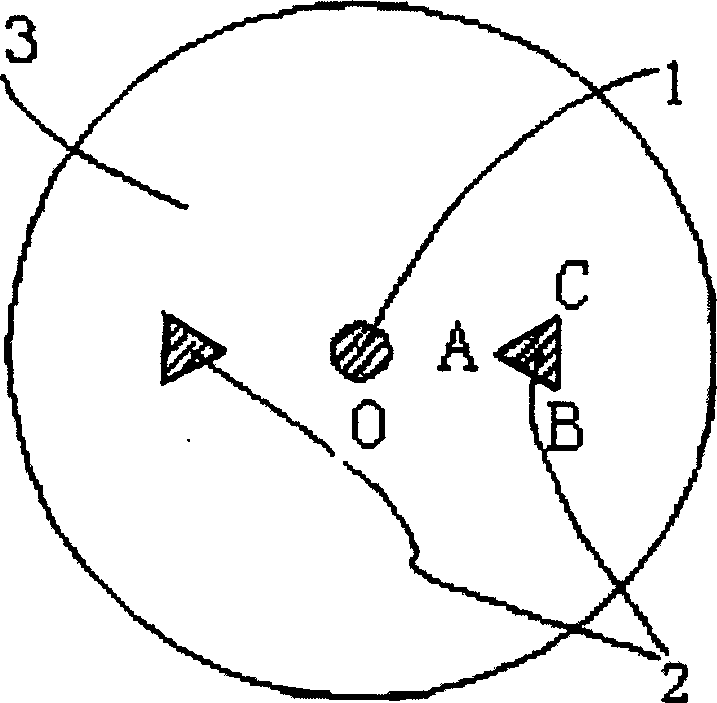

[0036] The waveguide structure of polarization maintaining fiber is as figure 1 As shown, it includes a core 1 with a circular section, and the core is covered with a cladding 3 with a circular section centered on the core, and the two sides of the core are symmetrically arranged in the cladding. The cross-sectional shape is equilateral Triangular stress element 2, the vertex A of the triangle ABC stress element is located inside the cladding and points to the center of the fiber core, the bottom edge BC of the triangular stress element is located outside the cladding and perpendicular to the radius of the fiber core, the two triangles The cross-sections of the stress elements are equal in size and equal in length to the fiber core.

[0037] The manufacturing method of the polarization-maintaining optical fiber is as follows: first, a single-mode mandrel with a diameter of 2mm is manufactured by PCVD; the doped B 2 o 3 Stress rods (SAP), doping molar concentration range 12% ...

Embodiment 2

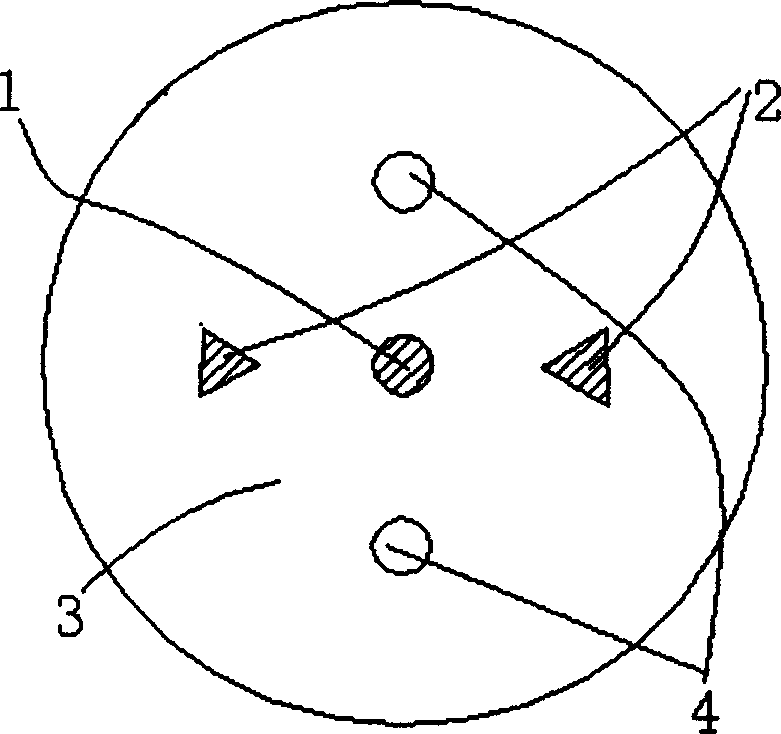

[0039] The main difference between the second embodiment and the first embodiment is that the stress element 2 whose cross-sectional shape is an isosceles triangle is arranged symmetrically on both sides of the fiber core 1 in the cladding layer 3, and the apex angle of this triangular stress element is 90° and point to the center of the fiber core, the bottom edge of the triangular stress element is located outside the cladding and is perpendicular to the radius of the fiber core, the two waist angles are 45°, and other structures are the same as in Embodiment 1.

[0040] The manufacturing method of the present embodiment is the same as that of the previous embodiment, adopting PCVD to manufacture a single-mode mandrel, the mandrel diameter is 2mm; manufacture doped stress rods with MCVD, then be processed into two sides whose length is 12.6mm (i.e. AC=AB=12.6mm), the other side is an isosceles right triangle with 17.8mm (ie BC=17.8), the mandrel and the stress rod are combine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com