Process for extracting aloinose

An aloe vera polysaccharide and extraction process technology, applied in the field of aloe vera polysaccharide extraction process, can solve the problems of difficulty in separation, extraction and purification, low content of aloe vera polysaccharide, failure to put into production, etc., and achieves cost reduction, simple process, and alcohol consumption saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

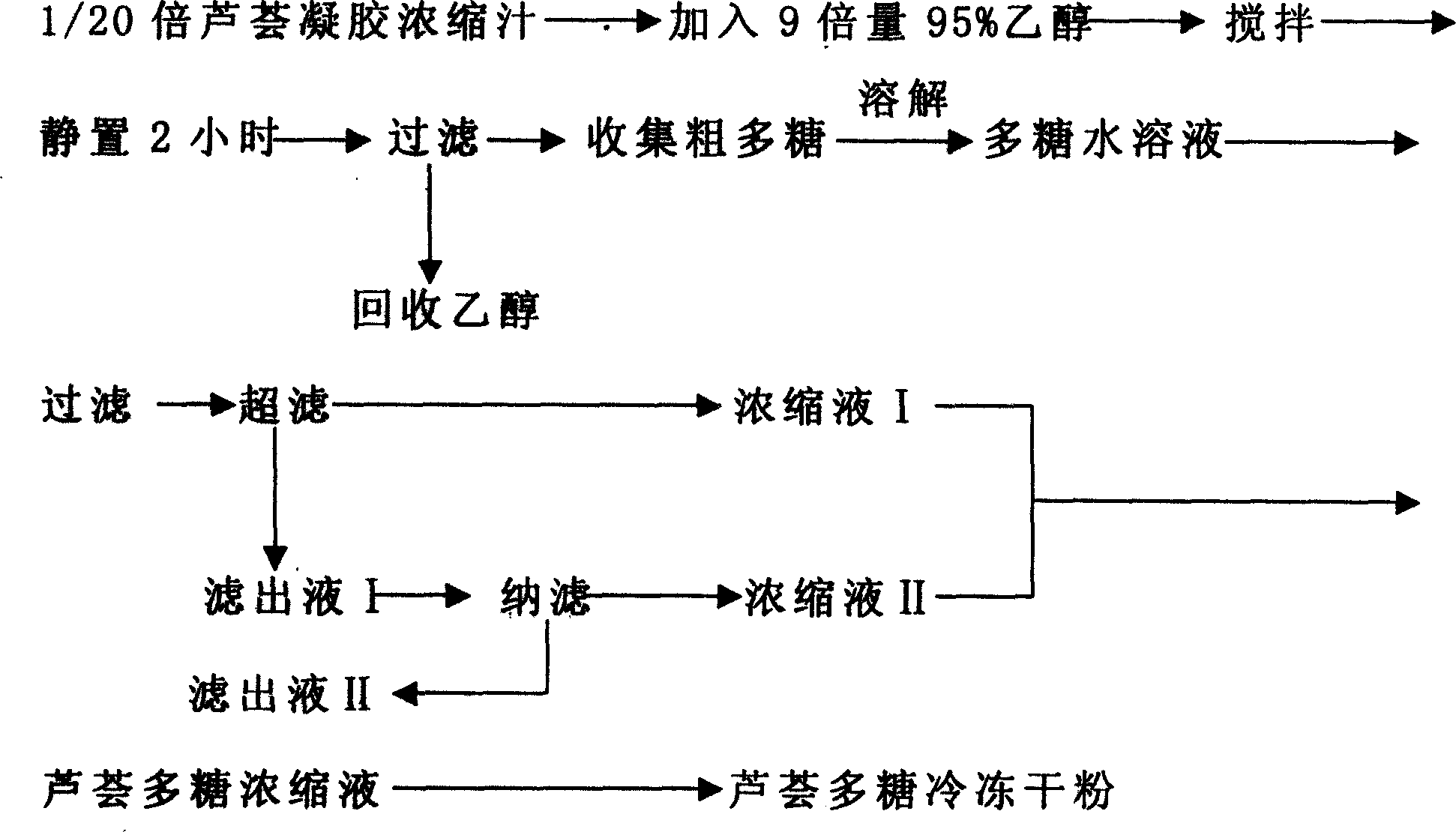

[0009] Referring to the accompanying drawings, after the fresh leaves of aloe are picked, they are soaked in clear water for a period of time and washed. Soak in disinfectant for 15 minutes, rinse with clean water, cut the leaf sheath and trim the leaf tip, peel off the skin, mash the mesophyll into a colloid, and carry out biological depreciation. Pass the aloe vera gel juice after decondensation through a three-legged centrifuge to obtain a centrifugal supernatant, take the supernatant and pass it through an ultrafiltration membrane and then a nanofiltration membrane, collect the concentrated solution that has passed through the ultrafiltration membrane and nanofiltration membrane, and obtain the aloe Aloe Vera Gel Concentrated Juice with 1 / 20 of the original juice. Add 9 times of 95% ethanol to the concentrated aloe vera gel, stir well at room temperature, and let stand for 2 hours. Filtrate, recover ethanol, collect the crude polysaccharide, wash the filter cloth with wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com