Interrupter method for producing high-purity methyl sulfonyl chloride

A methylsulfonyl chloride, high-purity technology, applied in the field of organic synthesis in the chemical industry, can solve the problems of high trace impurity content, specific equipment, complex and other problems, and achieve the effects of improving product yield, high product purity, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

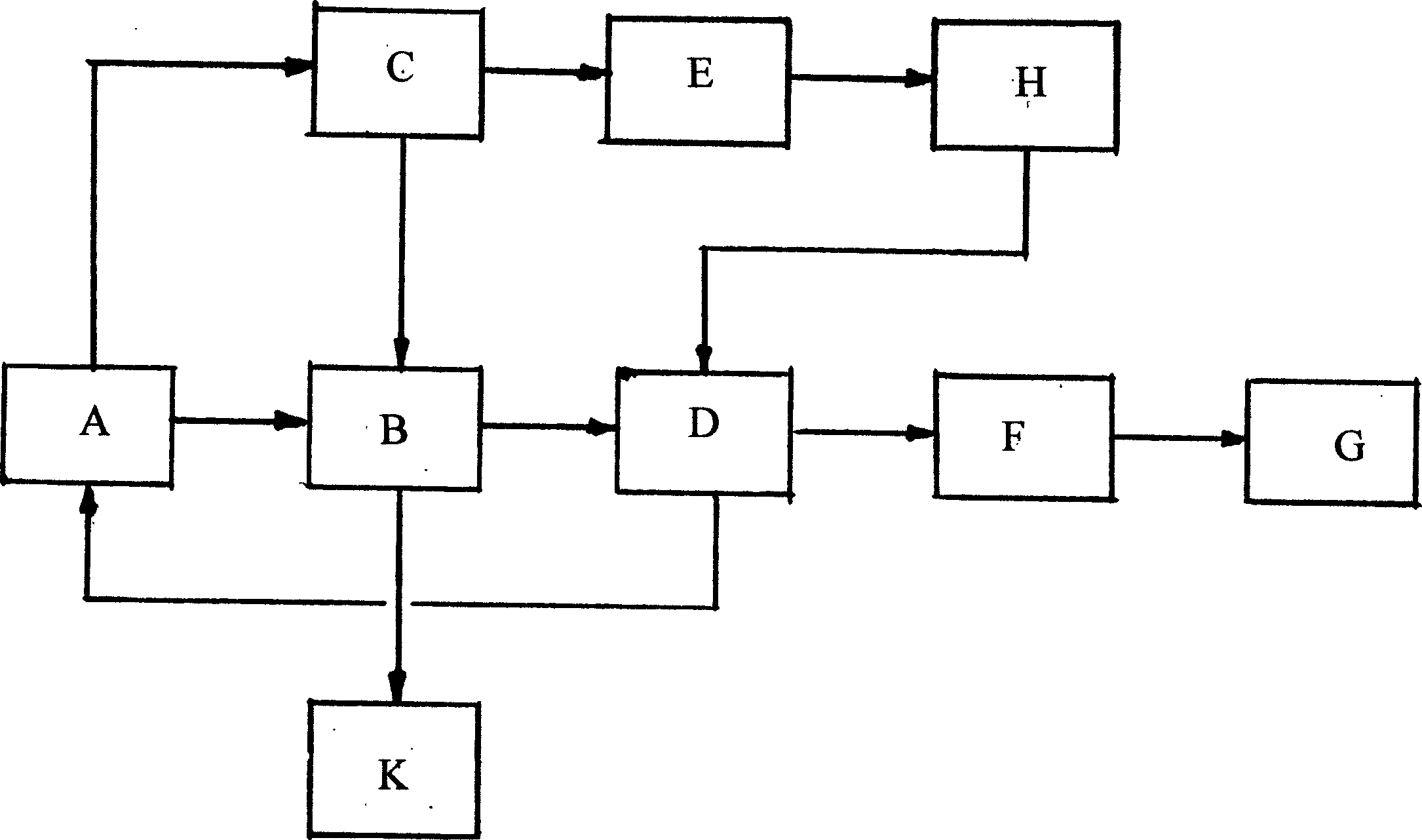

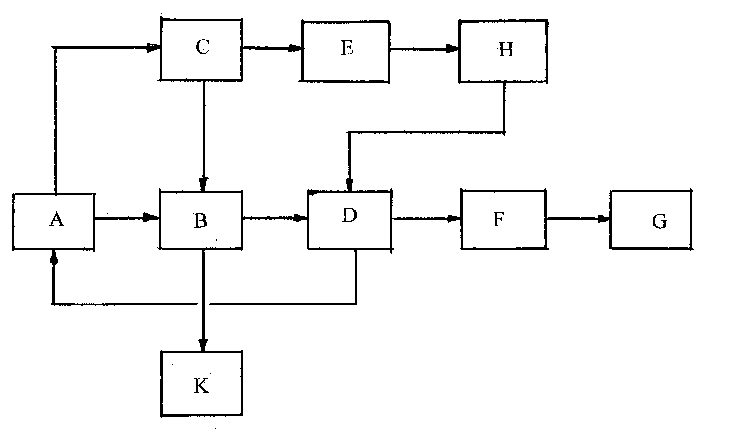

Image

Examples

specific Embodiment approach

[0023] The following examples are used to illustrate the present invention, but not to limit the present invention.

Embodiment

[0025] Add 1000KG dimethyl disulfide and 1800KG 30% recovered hydrochloric acid to the 3000L chlorination kettle, after cooling to 20°C, control the temperature in the kettle to be 20-30°C, and then feed chlorine gas. After 20-25 hours of passing chlorine, the end point of the reaction is reached, and the reaction solution is sent to a stratifier to stand for 10-12 hours to separate layers. The stratified crude product is sent to the washing tower of Φ400, and is washed countercurrently with 1000-1100KG30% recovered hydrochloric acid. The crude methanesulfonyl chloride after washing is sent to rectification under reduced pressure, and intermittent rectification is carried out at 40-60 mmHg (absolute), to obtain the finished product of methanesulfonyl chloride (hereinafter referred to as finished product 1).

[0026] Layered to obtain 800-900KG hydrochloric acid aqueous solution and 30% impurity-containing washing hydrochloric acid (1000-1100KG) combined, sent back to the chlor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com