Process for synthesizing (CH3)2 SiCl2 by utilizing CH3 SiCl2

A CH3, alkylation technology, applied in chemical instruments and methods, compounds of Group 4/14 elements of the periodic table, organic chemistry, etc., can solve the problems of low yield, poor safety, large amount of catalyst, etc. The effect of good safety, full and reasonable utilization, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

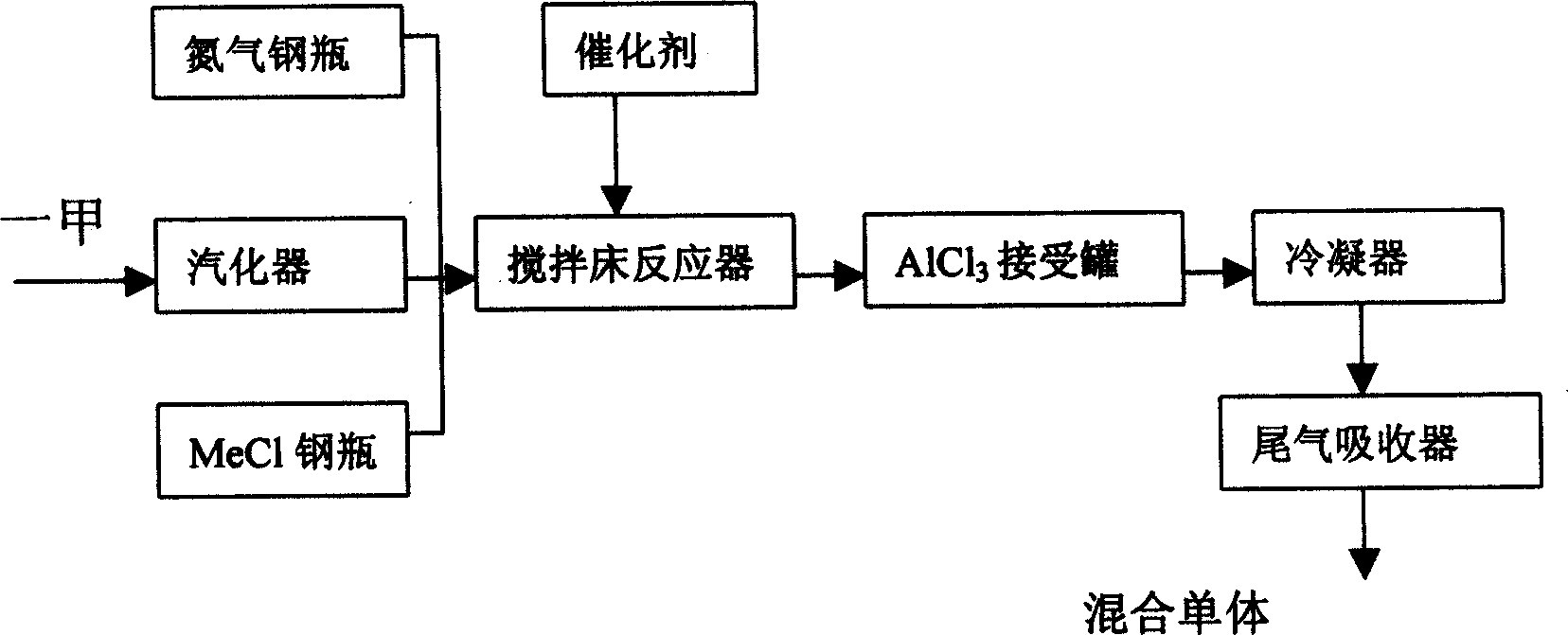

Image

Examples

example 1

[0041] Add 1KgAl ball into the stirred bed reactor, stir, pass N 2 Raise the temperature to 240-260°C, and feed CH into the reactor 3 SiCl 3 and CH 3 Cl, CH 3 SiCl 3 :CH 3 Cl=1:1:(mol), control the reaction temperature at 240-300°C, and stop passing CH after 4 hours of reaction 3 SiCl 3 and CH 3 Cl, through N 2 Cool down, when down to room temperature, get liquid sample and analyze by gas chromatography, its composition is 49.7% (CH 3 ) 2 SiCl 2 and 8.9% (CH 3 ) 3 SiCl. CH 3 SiCl 3 Conversion rate is 67.2%, (CH 3 ) 2 SiCl 2 and (CH 3 ) 3 The total yield of SiCl per pass is 58.6%. Example two:

example 2

[0042] Reaction method is the same as Example 1, CH 3 SiCl 3 :CH 3 Cl=1: 1: (mol), Al: 1Kg, NaCl: 500g, the reaction time is 4 hours, and the liquid product of gained is analyzed by gas chromatography, and its composition is 38.2% (CH 3 ) 2 SiCl 2 and 17.5% (CH 3 ) 3 SiCl. CH 3 SiCl 3 Conversion rate is 65.2%, (CH 3 ) 2 SiCl 2 and (CH 3 ) 3 The total yield of SiCl per pass is 60.1%. Example three:

example 3

[0043] Reaction method is the same as Example 1, CH 3 SiCl 3 :CH 3 Cl=1: 0.6 (mol), the reaction time is 4 hours, and the liquid product of gained is analyzed by gas chromatography, and its composition is 40.6% (CH 3 ) 2 SiCl 2 and 2.4% (CH 3 ) 3 SiCl. CH 3 SiCl 3 Conversion rate is 58.7%, (CH 3 ) 2 SiCl 2 and (CH 3 ) 3 The total yield of SiCl per pass is 50.4%. Example four:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com