Method and special equipment for preparing granular silicon belt

A technology of granular silicon and particle diameter, which is applied in the direction of final product manufacturing, sustainable manufacturing/processing, electrical components, etc., can solve the problems of high preparation cost, high substrate cost, and the inability to reduce the production cost of polycrystalline silicon thin film batteries, etc., to achieve production Low cost, simple process, no effect of radiation pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

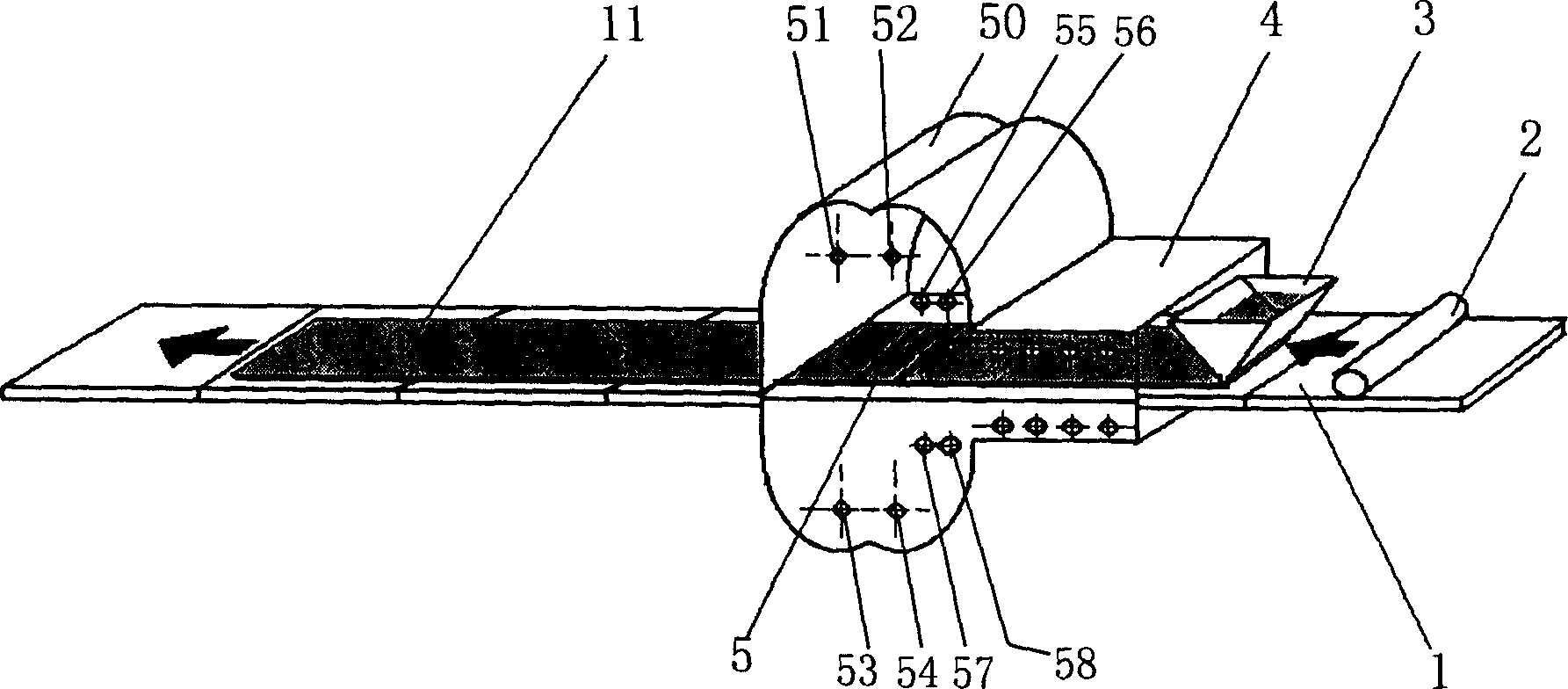

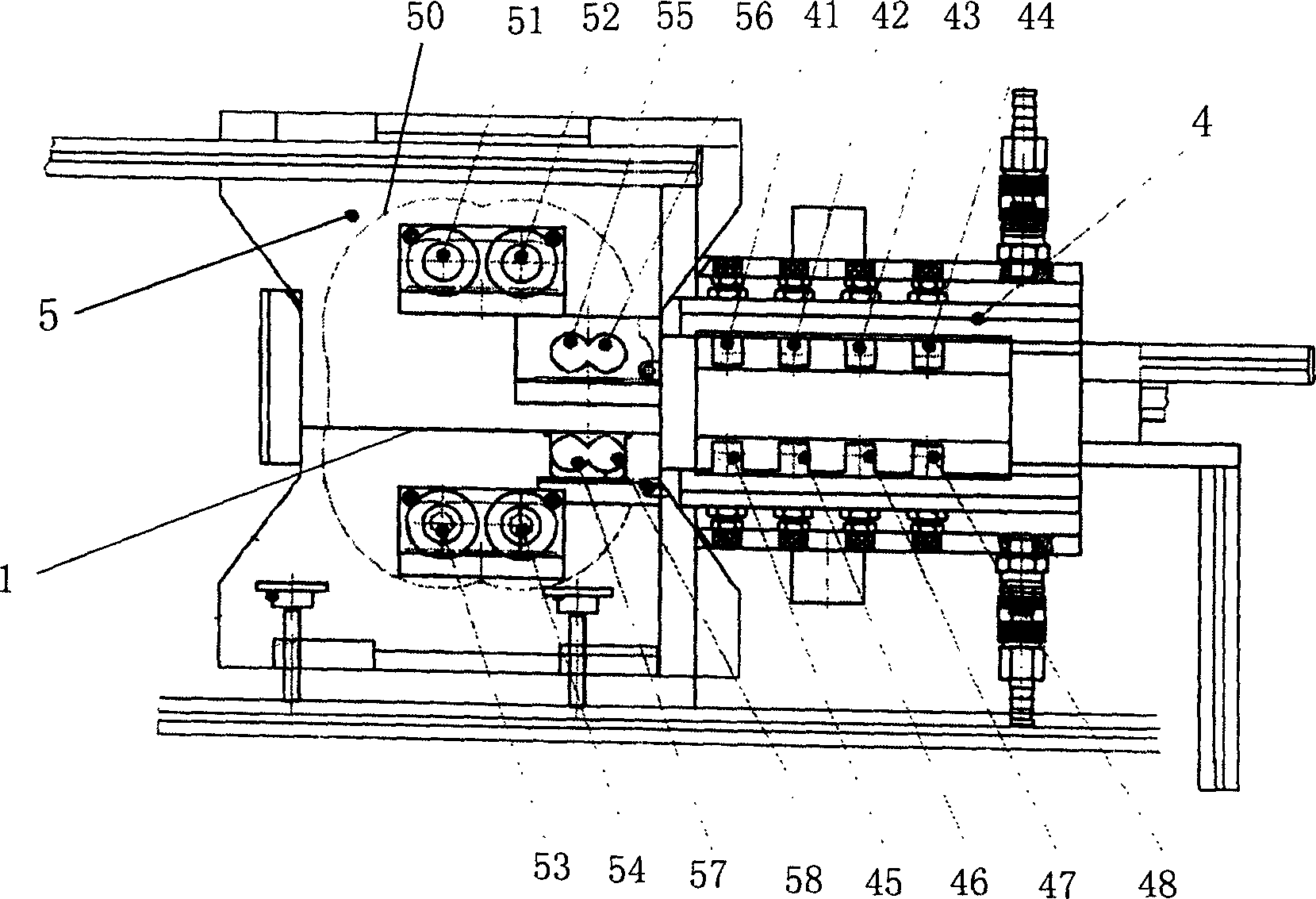

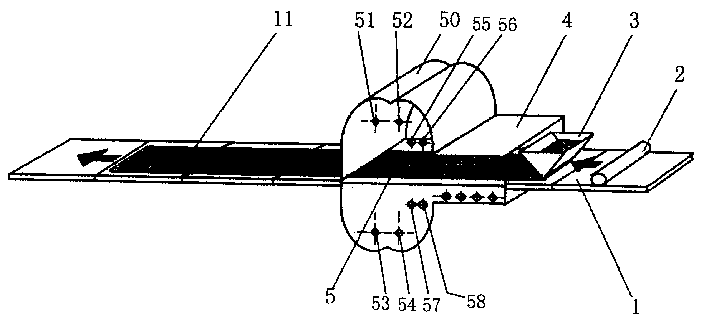

[0026] This embodiment adopts as figure 1 The preparation device for the granular silicon tape is shown. In this device, 1 is a transmission support plate (made of quartz material), and 2 is a mechanical transmission device, through which the transmission support plate 1 can be driven to move forward continuously in the horizontal direction, in the order of front and back on the transmission path of the transmission plate The feeding funnel 3, the preheating zone 4, the line focus heating zone 5 and the natural cooling zone 6 are arranged in sequence; in the preheating zone, there are two rows of 8 non-focusing tungsten halogen lamps 41, 42 respectively arranged on the upper and lower sides of the transmission plate. . The reflector 50 adopts a double oval reflector lampshade. There are four halogen tungsten lamps 51, 52, 53, and 54 respectively arranged at the focus positions of the double oval reflector lampshade 50, and there are four halogen tungsten lamps for auxiliary h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com