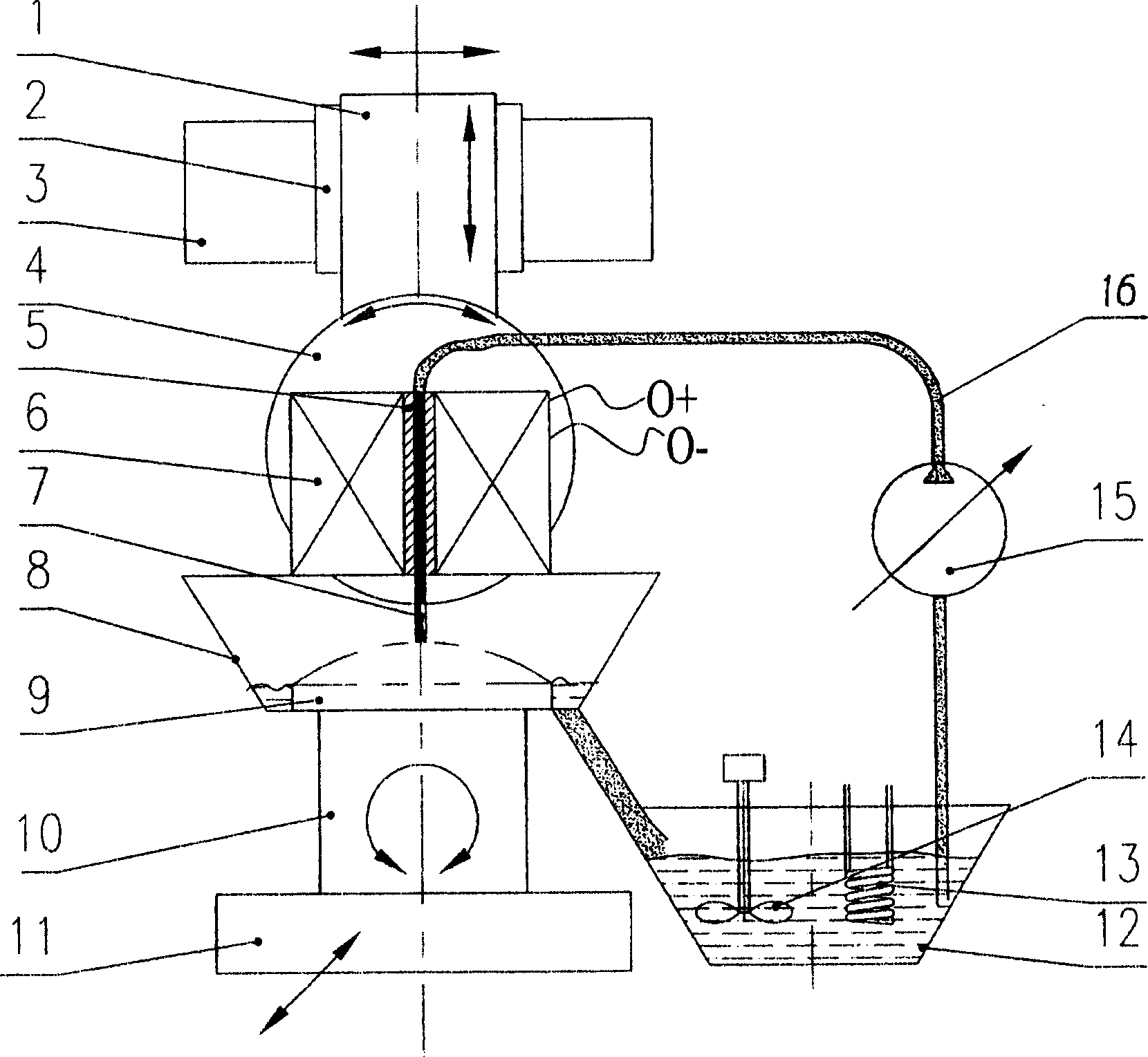

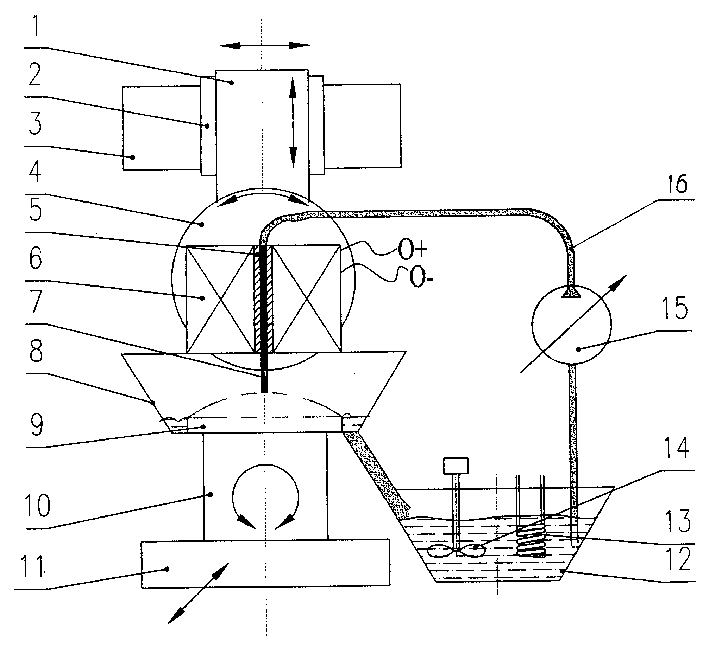

Deterministic magnetic jet-flow finishing method and apparatus

A finishing processing and magnetic jet technology, which is applied in the direction of explosion generating devices, metal processing equipment, manufacturing tools, etc., can solve the problems of stagnant processing technology of large optical parts, reduce the versatility of computer control technology, etc., and achieve high surface quality and the effect of shape accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

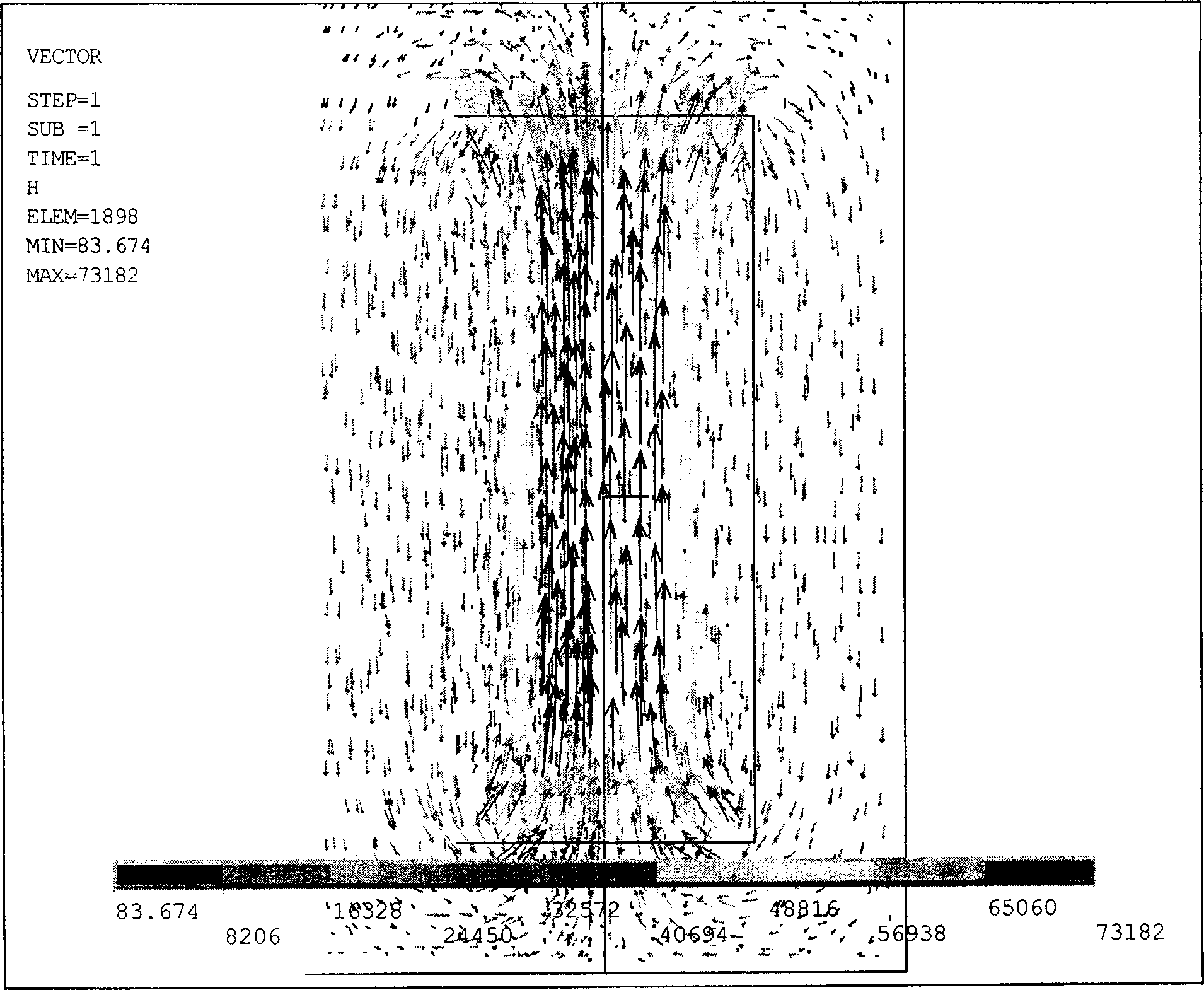

Method used

Image

Examples

Embodiment Construction

[0010] The present invention is realized by using a "controllable" jet base fluid - magnetorheological fluid. The formula of the magnetorheological fluid is: 30%-40% Volume of carbonyl iron powder, 50%-60% Volume of water, 4%-8% Volume of abrasive, 1%-5% Volume of stabilizer. Magnetorheological fluid is an emerging smart material with promising development and engineering application value. Magnetorheological fluids with good performance can produce obvious magnetorheological effects under the action of a magnetic field, that is, rapid and reversible transitions between liquid and solid states, and this transition is completed within milliseconds. During this process, the viscosity of the magnetorheological fluid remains continuous and changes steplessly. The entire conversion process is extremely fast and controllable, with minimal energy consumption, and real-time active control can be realized. This is because when there is no external magnetic field, the magnetic moments ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com