Method of crystallization

A crystallization and crystal technology, applied in the field of separation process of pure terephthalic acid crystals, can solve problems such as filter blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

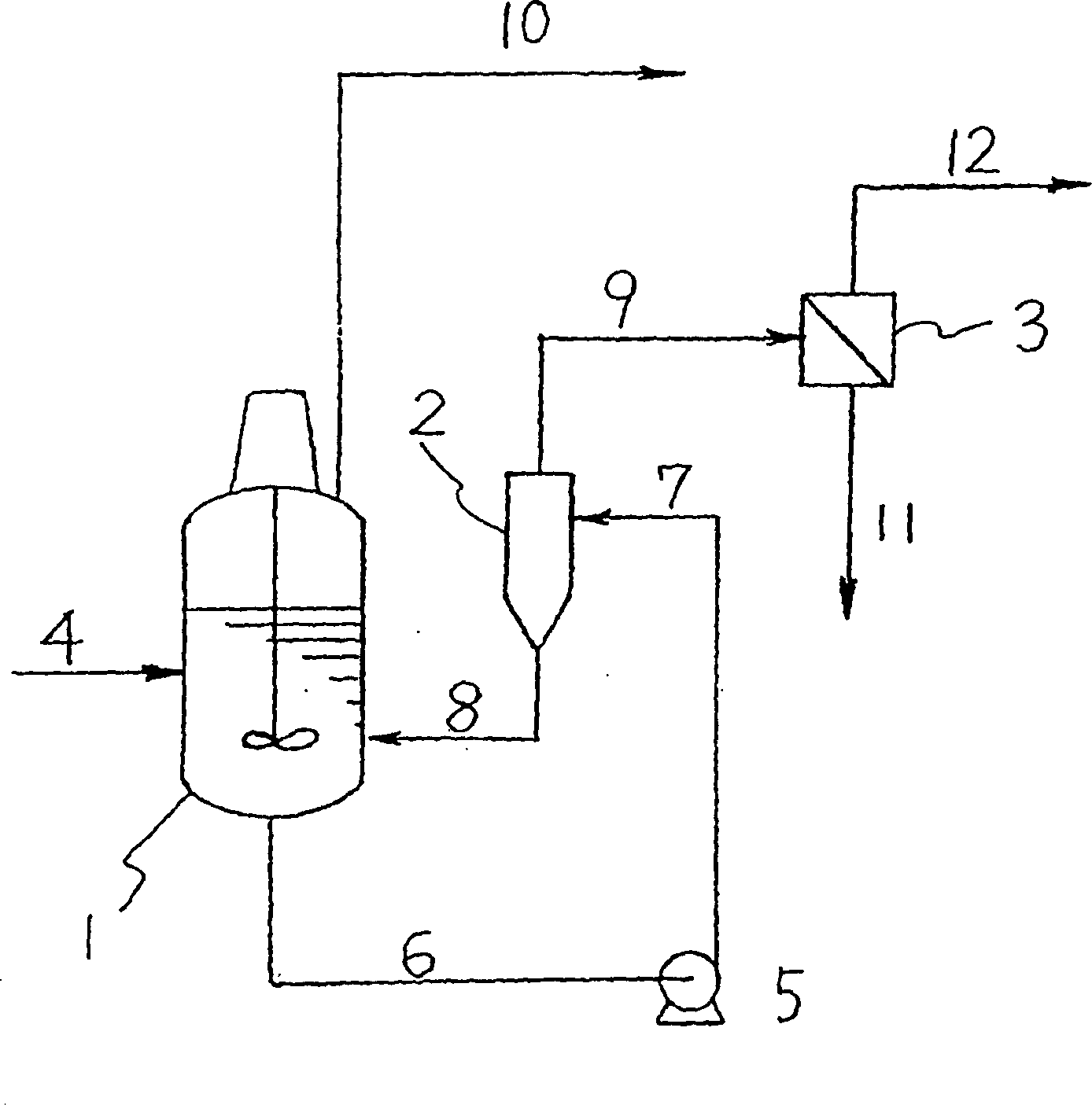

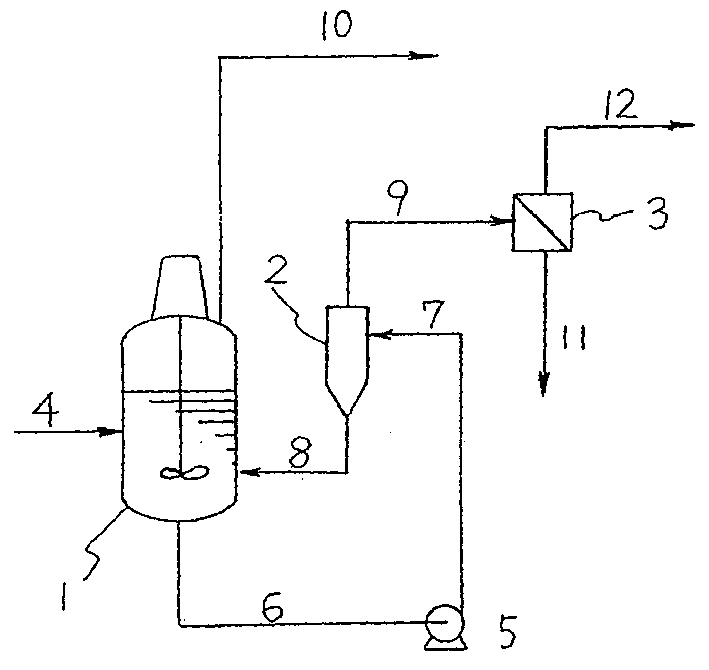

[0052] In a plant for the production of pure terephthalic acid by catalytic hydrotreating of a solution of crude terephthalic acid obtained from the liquid-phase oxidation of p-xylene in water, the figure 1 The device shown in the system diagram performs crystallization operation on the first mother liquor product obtained by the mother liquor replacement method.

[0053] The first mother liquor product obtained by the mother liquor replacement method is sent to the crystallization vessel 1 through the first mother liquor product feed pipe 4 at 145° C., and the operation is performed according to the system diagram. The amount of the first mother liquid product supplied to the crystallization vessel 1 is 100 parts of water and 0.3 parts of terephthalic acid partially present in crystals. Almost all other impurities are soluble in water.

[0054] In the crystallization vessel 1, the temperature of the first mother liquid product is lowered to 100° C. through flash vaporization...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com