P electrode structure on light exit side of LED

A technology of light-emitting diode and electrode structure, which is applied to circuits, electrical components, semiconductor devices, etc., and can solve problems such as inability to implement low-voltage driving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

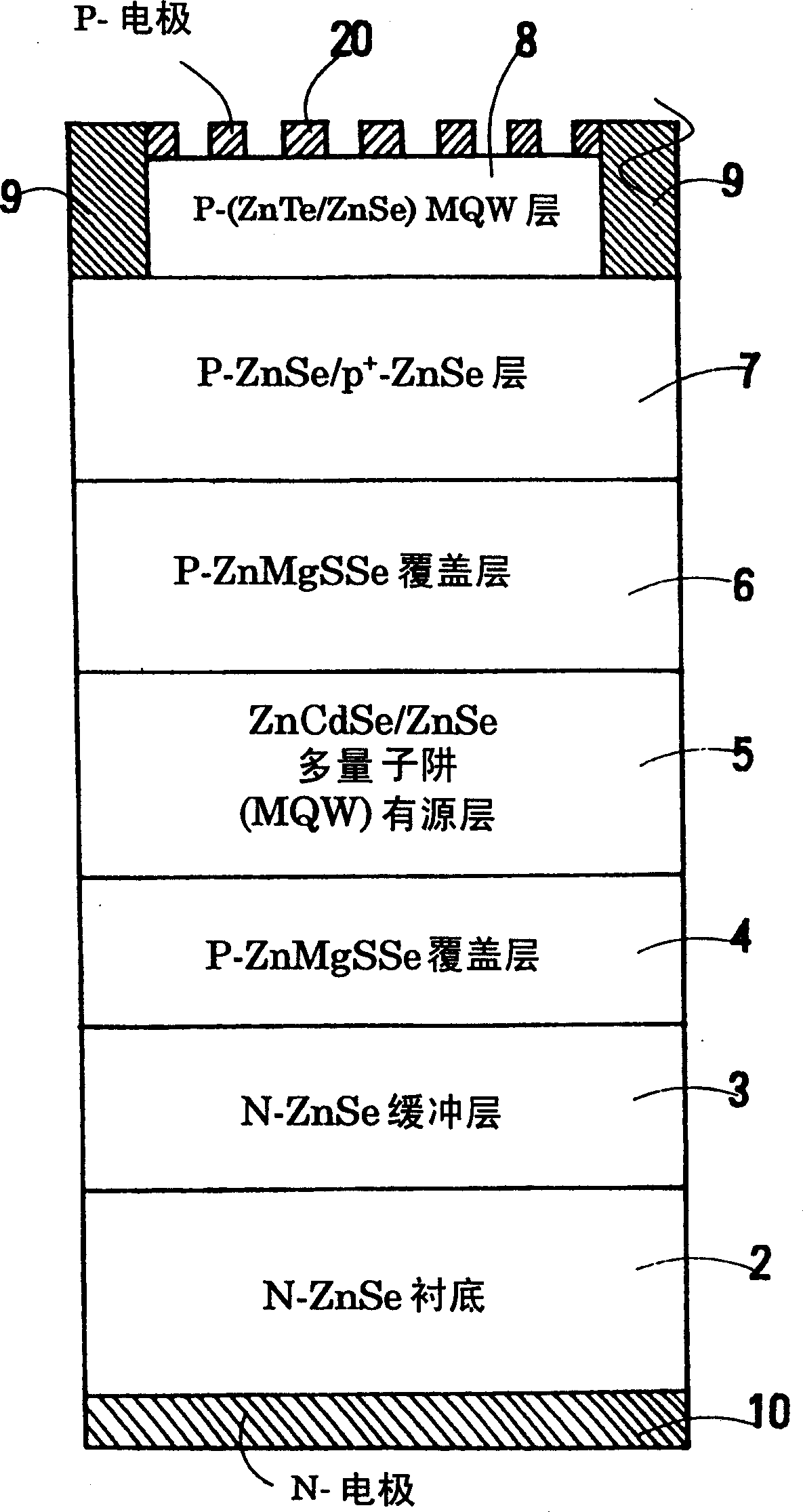

[0110] Specific embodiments of the present invention will be described below with reference to the drawings. The same numerals or symbols in each figure denote the same components to avoid repeated explanations. The dimensional ratios in the drawings do not necessarily agree with those described. [a. Material of light-emitting element]

[0111] The present invention aims to improve LEDs using ZnSe or GaN, which have a wide bandgap and exhibit high resistivity even when deposited with impurities due to the lack of charge carriers. [b. Shape of electrode]

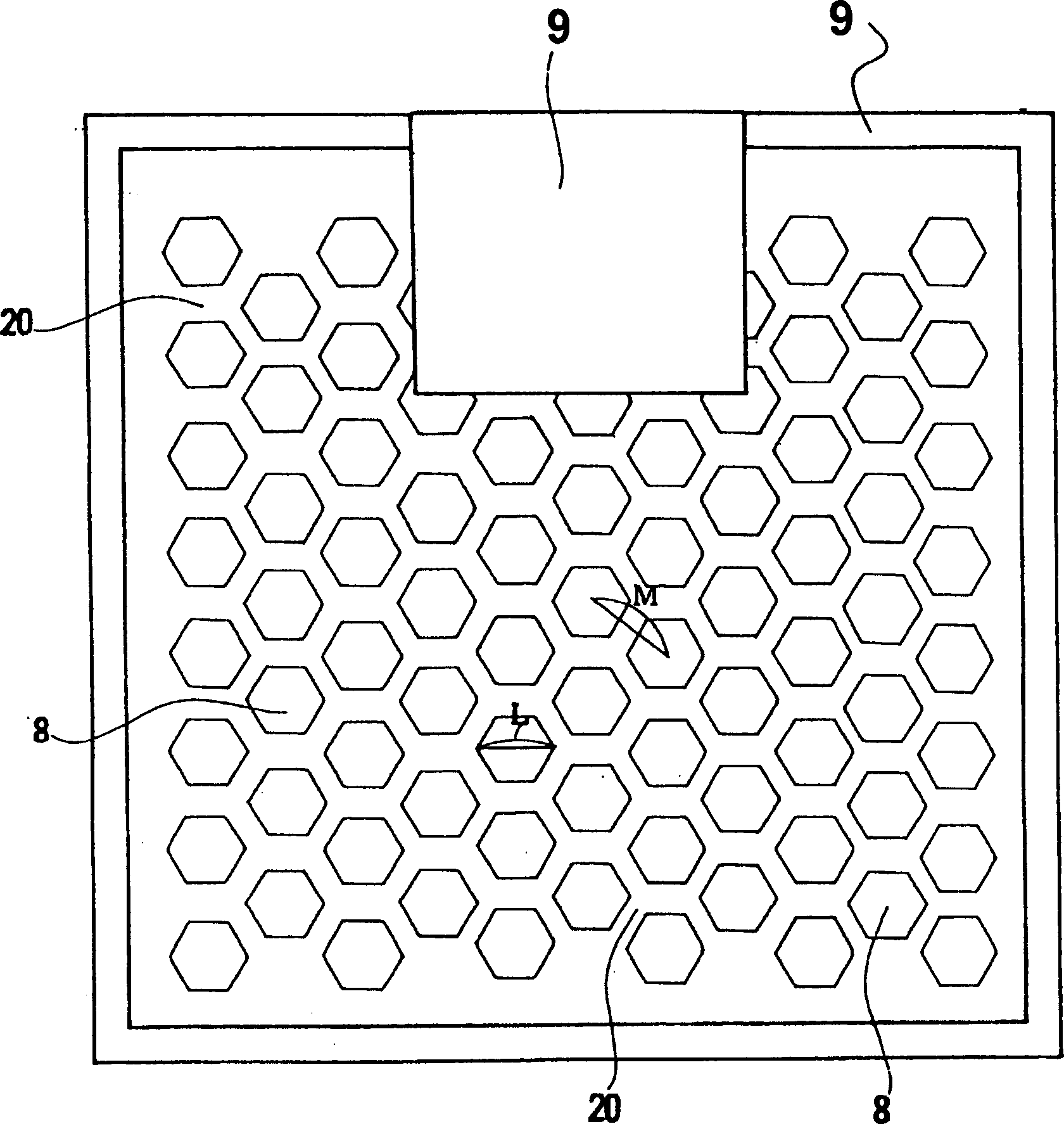

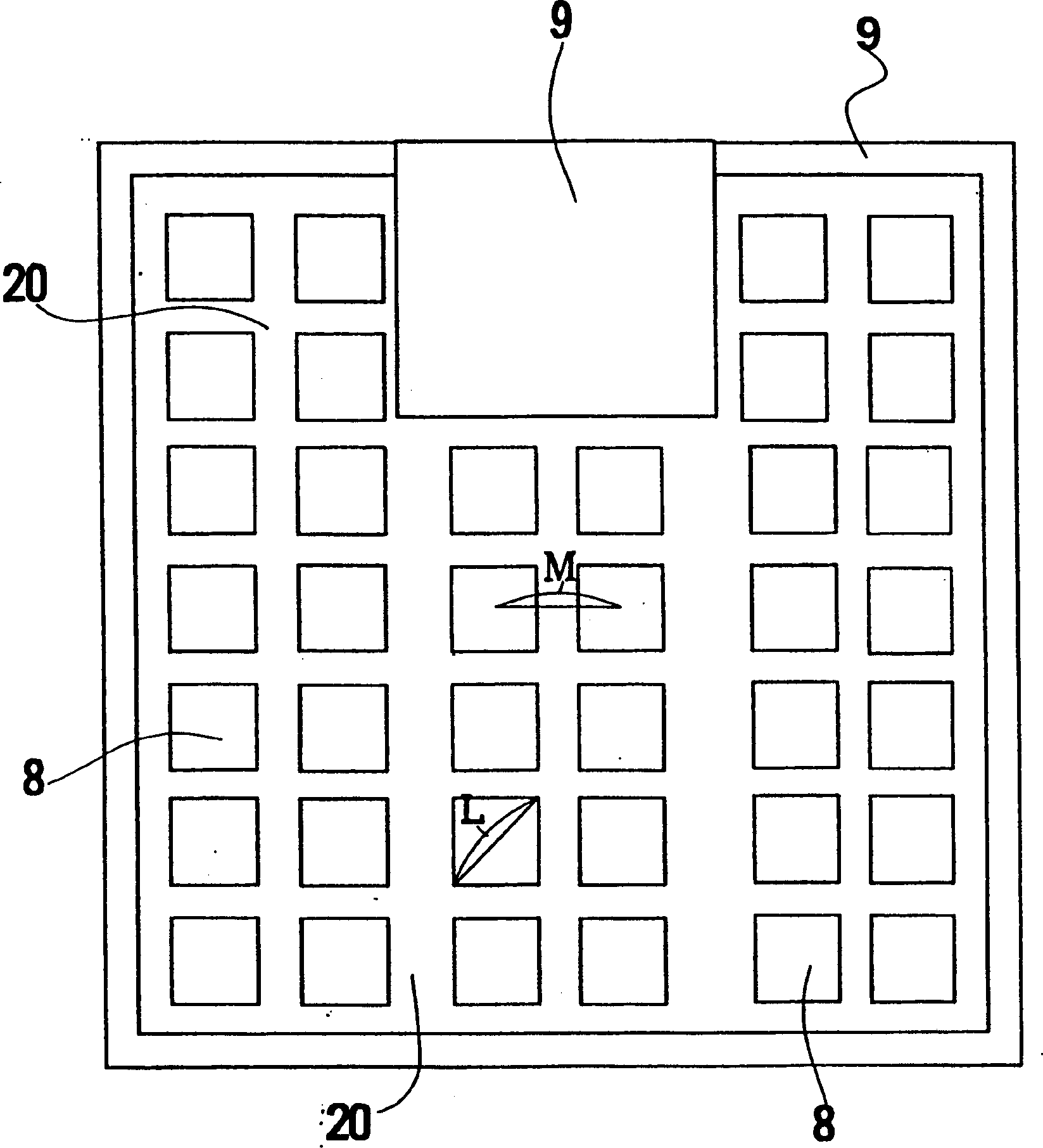

[0112] The present invention aims to improve the shape of the p-electrode from which light emerges. [c.p-type contact layer]

[0113] With wide bandgap semiconductors such as ZnSe or GaN, p-type impurities are not easily deposited. Even when deposition is achieved satisfactorily, the activity ratio is low, and in many cases, not many positive holes are excited from the acceptor. Therefore, the number of p-type carriers ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com