Interlayer arrangement structure for multilayer circuit board

A technology of multi-layer circuit board and configuration structure, applied in the direction of multi-layer circuit manufacturing, printed circuit, electrical components, etc., can solve the problem of inability to meet high-frequency signal requirements, inability to provide connection between power supply layers and operating components, and the density of via holes. restrictions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

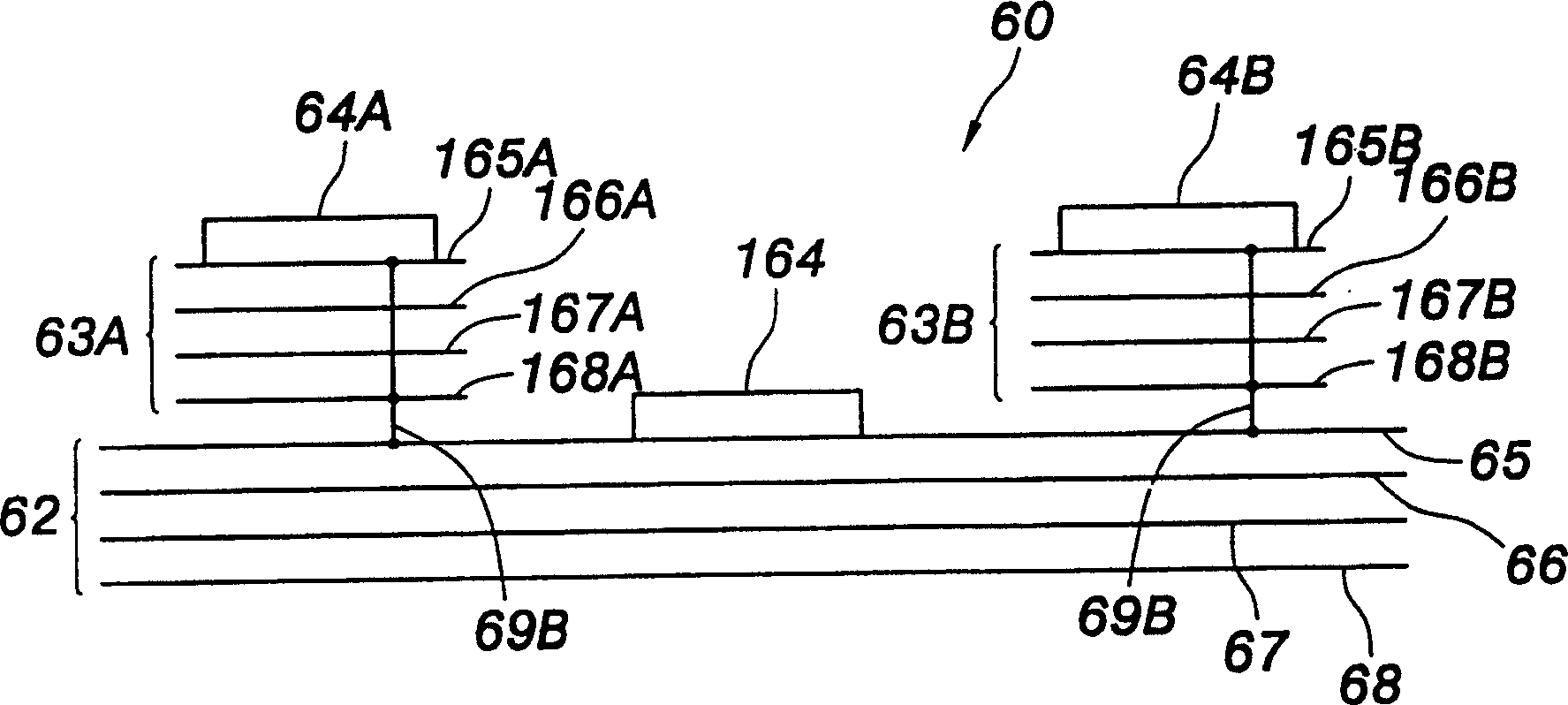

[0018] First see Figure 3A , Figure 3B and Figure 3C , which are schematic plan views of the power supply layer 100 , the component layer 200 , and the soldering layer 300 in the preferred embodiment of the present invention, respectively. Since the ground layer is made of uncut copper foil and is electrically connected to the ground potential, it will not be described in detail. Figure 3A The power supply layer 100 is also basically composed of copper foil, but is cut into several power supply planes 102, 103, 104 and 105, 106 that can provide working voltage, and a reference ground 107 connected to the ground potential. , 108 and 109, wherein the power blocks 102, 103, 104, 105, 106, and the reference grounding areas 107, 108, 109 are isolated from each other by an isolation line 111 to prevent mutual interference. The setting positions of the reference ground areas 107, 108, and 109 correspond to the signal layout areas on the solder layer 300 (in the Figure 3B and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com