Harvester equipment of crops and its transmission method

A harvesting device and technology for crops, applied in harvesters, agriculture, cutters, etc., can solve problems such as unreliability and limited power, and achieve the effect of reliable speed ratio and simple and reliable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

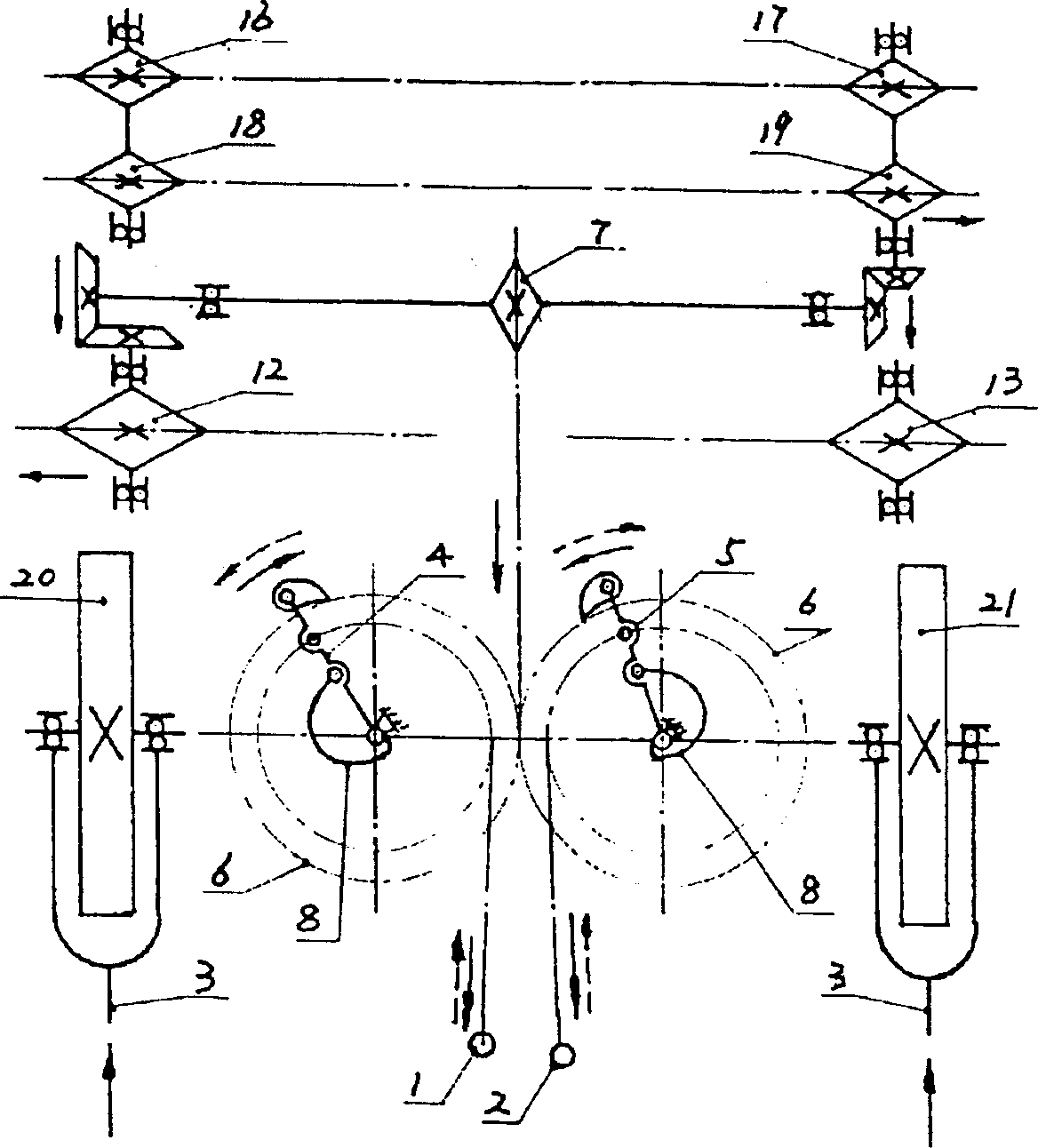

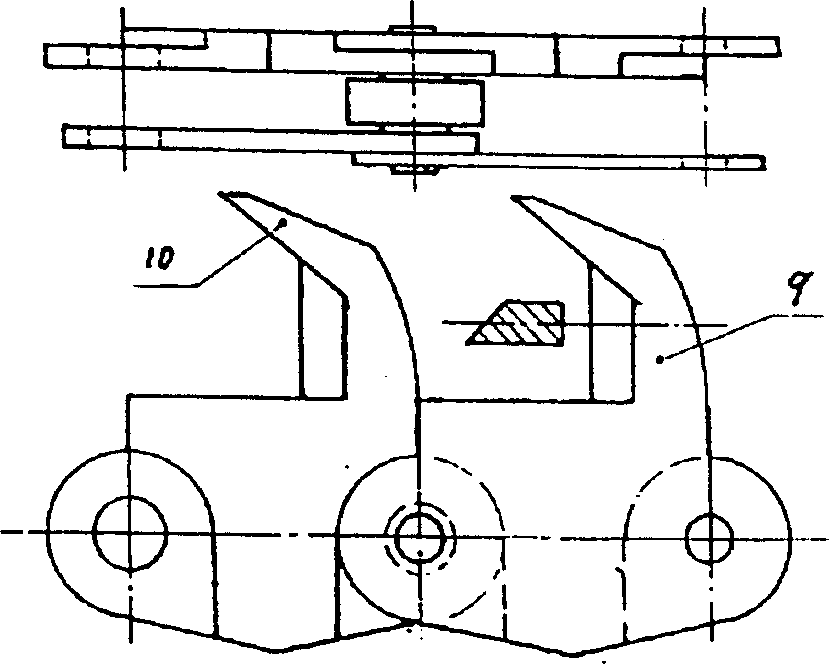

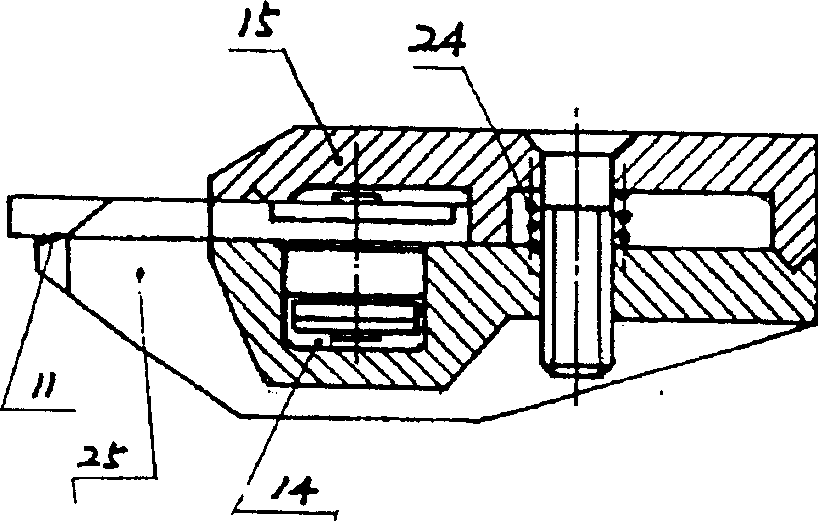

[0012] refer to figure 1 , 1,2 are two foot buckles, and they can be footwear but also bands, and their effect is to be able to be connected with the operator's feet. When the operator pushes the handle 3M device in the direction indicated by the arrow to move forward, he alternately locates on the ground is the two parts that will alternately drag the rod 4 through the transmission belt connected with the foot buckles 1 and 2, and the rod 5 passes through the spine. The claws alternately push the ratchet 6 in the direction shown by the solid arrow and complement each other on the ratchet 6 to form a continuous one-way push. Ratchet 6 is sprocket wheel again, and this sprocket wheel works through transmission chain transmission lower stage executive mechanism. Because the walking action of the operator's foot is relative to the harvesting device, it is an alternate reciprocating motion, and the reset action of the bar 4 and the bar 5 is completed by the coil spring 8 affixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com