Turbin steam condenser water chamber anticorrosion device and its manufacturing method

A technology of anti-corrosion and condenser, applied in the direction of damage protection, heat exchange equipment, lighting and heating equipment, etc., can solve the problems of eliminating corrosion, achieve the effect of controlling corrosion, good anti-corrosion effect, and improving user economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

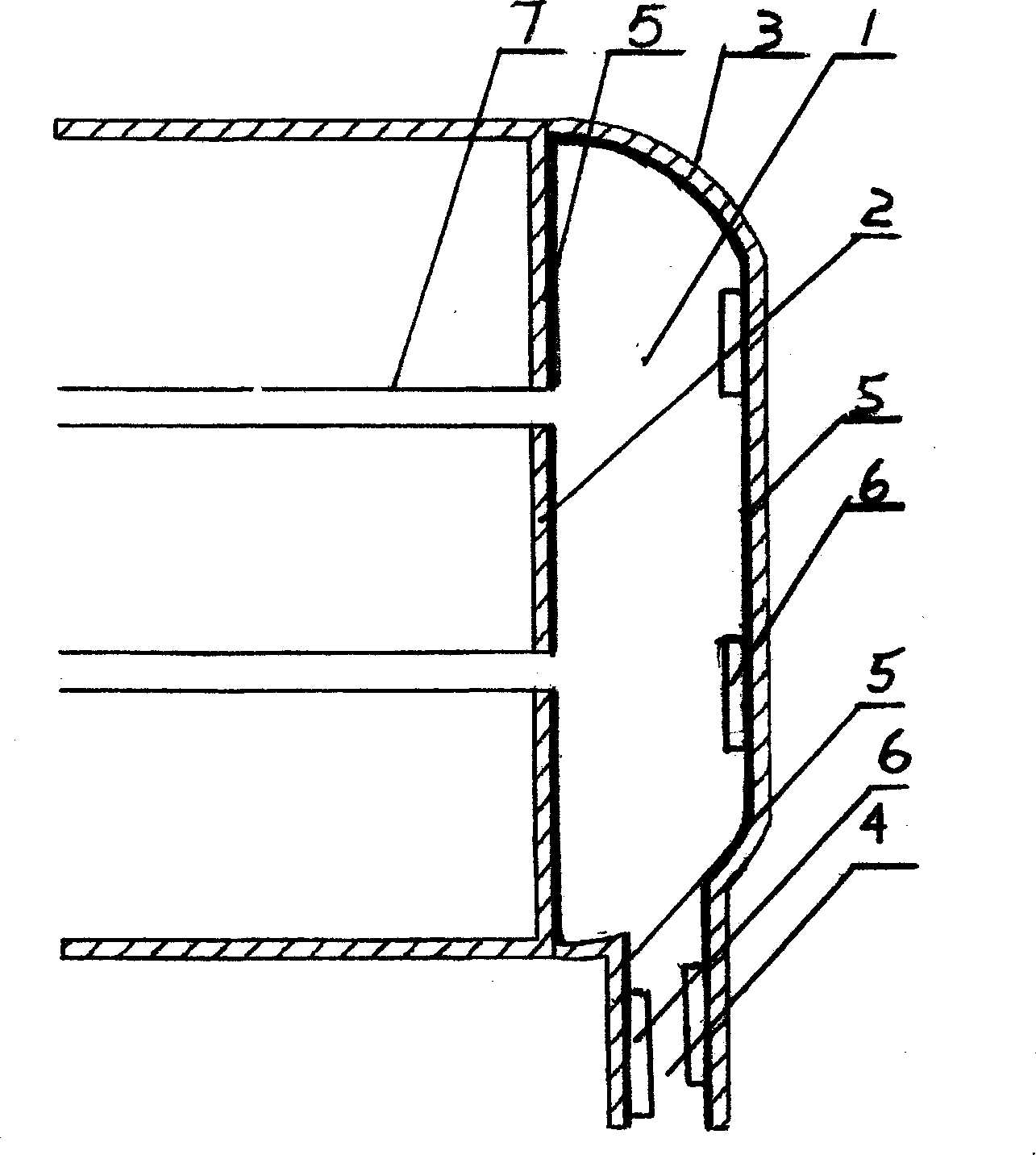

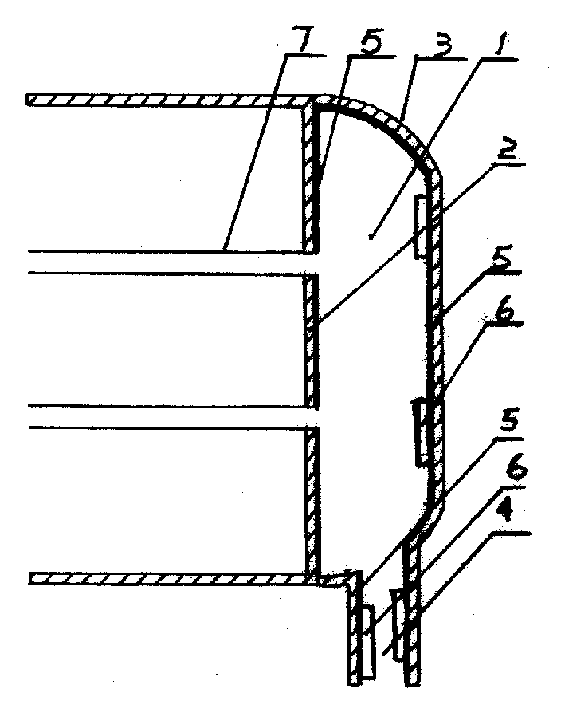

[0025] The structure of the water chamber of the steam turbine condenser is as follows: figure 1 As shown: the water chamber 1 is composed of a spherical wall 3 and an end tube plate 2 butted.

[0026] Firstly, an anti-corrosion coating 5 is made on the inner surface of the spherical wall 3 , the water side surface of the end tube plate 2 and the inner surface of the connecting pipe 4 . The method is: first clean and degrease the surface, sandblast and remove rust, and then thermally spray the aluminum protective layer with a thickness of 0.10-0.15mm; Sandblasting should be carried out as soon as possible after rust removal, usually not more than 4 hours; after thermal spraying aluminum, apply epoxy coal tar primer in time, and apply epoxy coal tar topcoat once after the surface is dry. Then install the sacrificial anode 6, in view of the heat excha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com