Expansion type flame resistant cable

A fire-resistant cable, expansion type technology, applied in the field of fire-resistant cables, can solve the problems that the cables do not have fire resistance, etc., to achieve the effect of preventing heat intrusion, stable heat insulation layer, and good fire resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

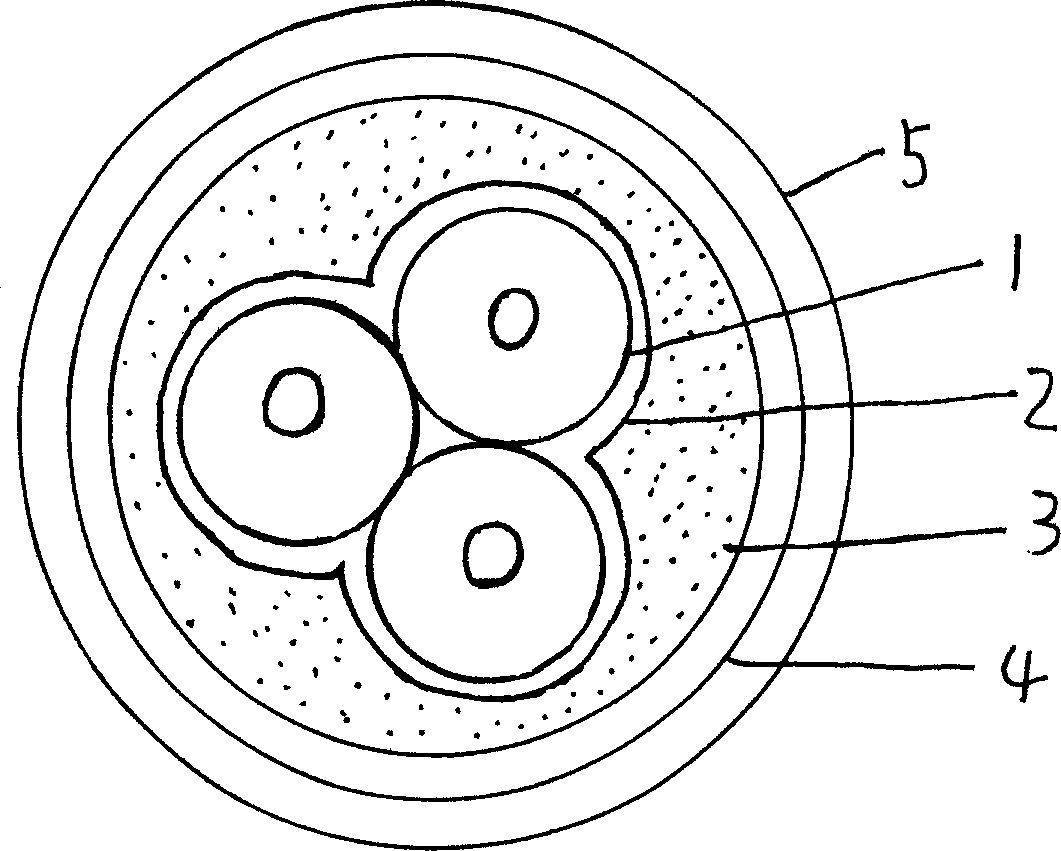

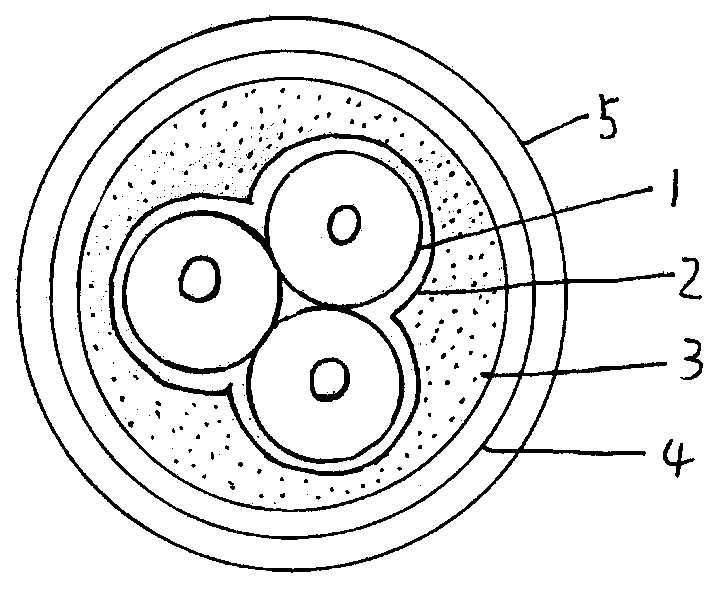

[0012] Examples, see figure 1 , an intumescent fire-resistant cable, the cable sheath 5 is provided with a plurality of insulated wire cores 1, the outer surface of the plurality of insulated wire cores 1 is provided with a spacer 2, and the spacer 2 is made of cross-linked polyethylene to play a waterproof role , the outer surface of the isolation sleeve 2 is filled with a mineral composite layer 3, the mineral composite layer 3 is mainly composed of aluminum hydroxide or magnesium hydroxide plus an expansion agent, the outer surface of the mineral composite layer 3 is provided with an expansion sleeve 4, and the expansion sleeve 4 is wrinkled In this way, when the mineral composite layer 3 is heated and expanded, the wrinkled refractory fabric will be forced to expand to increase the internal space. The outer surface of the expansion sleeve 4 is in contact with the inner wall of the sheath 5, and the sheath 5 is a halogen-free sheath or Sheathed in polyvinyl chloride.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com