Container

A container and container body technology, applied in the field of containers, can solve the problems of polluting the mouth of the cylinder, wasting time of manicure liquid, wasting manicure liquid, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

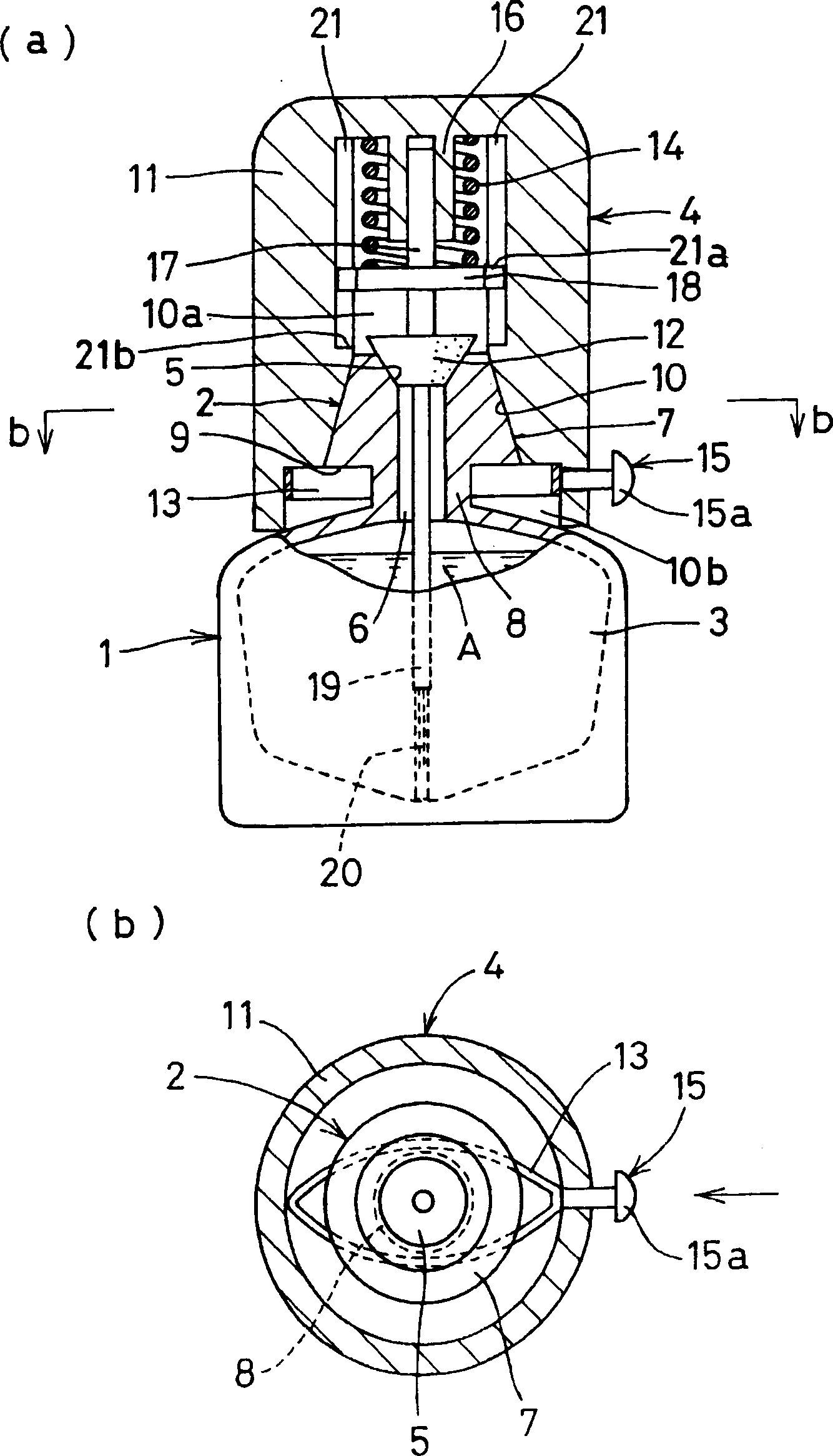

[0070] Figure 5 ~ Figure 8 It is Example 2 which shows the container of this invention. Here, the same reference numerals will be assigned to the same parts as those in the first embodiment described above, and will be described.

[0071] The container 1 of this embodiment 2, the barrel mouth 2 that is provided with on the top of container body 3, by the conical barrel portion 31 of lower large diameter and the small-diameter shaft portion 32 that links to each other with the lower end of this conical barrel portion 31, and the small-diameter shaft portion 32 Composed of connected large diameter portions 33 , a locking step 9 is formed under the conical cylinder portion 31 . Meanwhile, the upper end of the container body 3 is flat around the lower portion of the large diameter portion 33 .

[0072] Cover 4, the inner diameter of the lower part of the cover body 11 is formed as a cavity 34 that fits externally on the mouth 2 with a margin, and the cylindrical portion 35 forme...

Embodiment 3

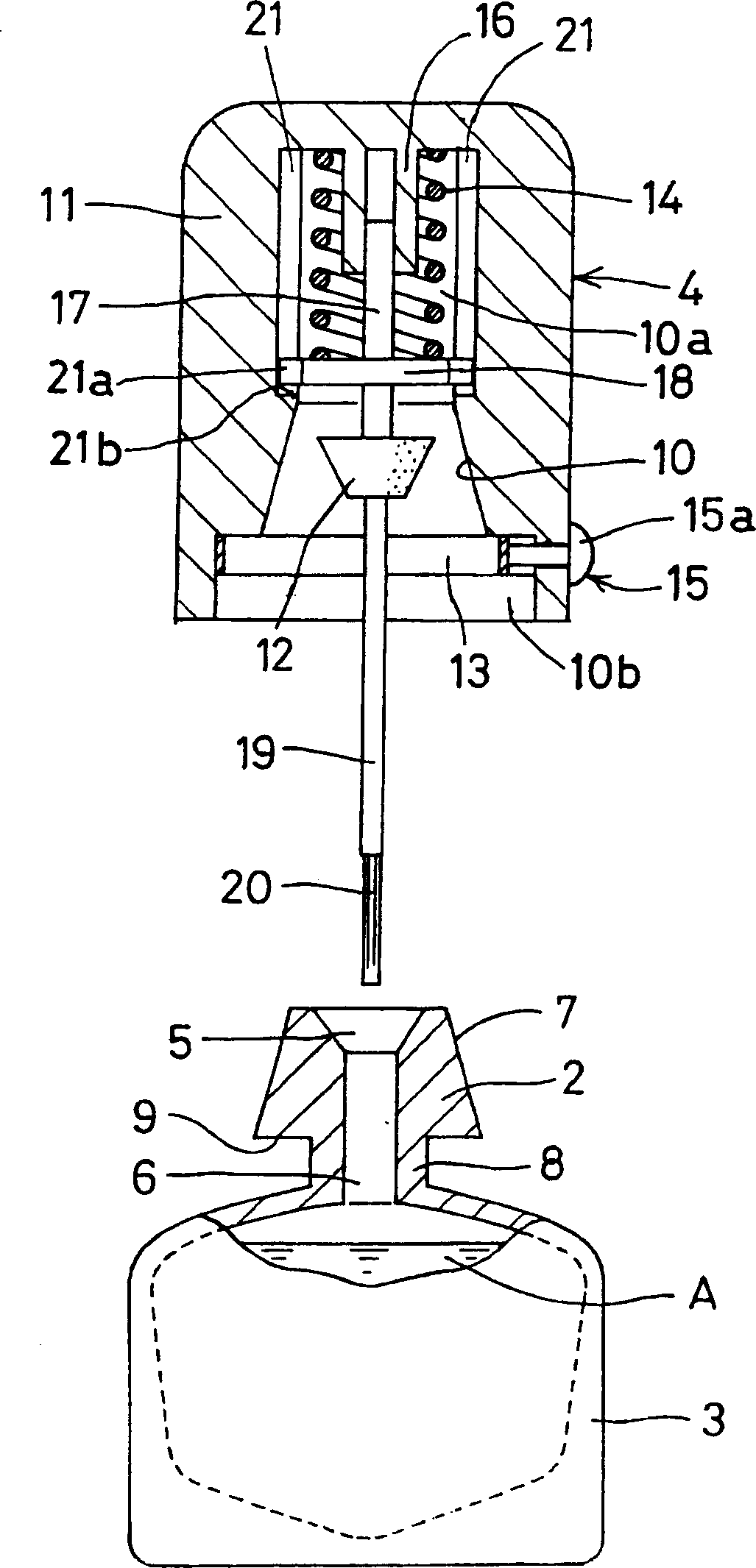

[0088] Figure 9 ~ Figure 11 It is Example 3 which shows the container of this invention. Here, the same reference numerals are assigned to the same parts as in the first and second embodiments described above.

[0089] In this third embodiment, the lock release mechanism for pressing the elastic lock member 13 in the longitudinal direction is also performed by pressing down from the upper part of the cover body 11 . In the illustrated example, it is used together with the lock release mechanism 15 in the second embodiment described above.

[0090] The lock release mechanism 15b of the third embodiment is composed of a pressing member 51 arranged on the top of the cover body 11 and movable up and down, and arranged on both sides of the elastic locking member 13 along the long axis direction inside the cover body 11, A vertically long elevating rod 52 that moves up and down integrally with the pressing member 51 and a spring 53 that provides resilience to the upward position ...

Embodiment 4

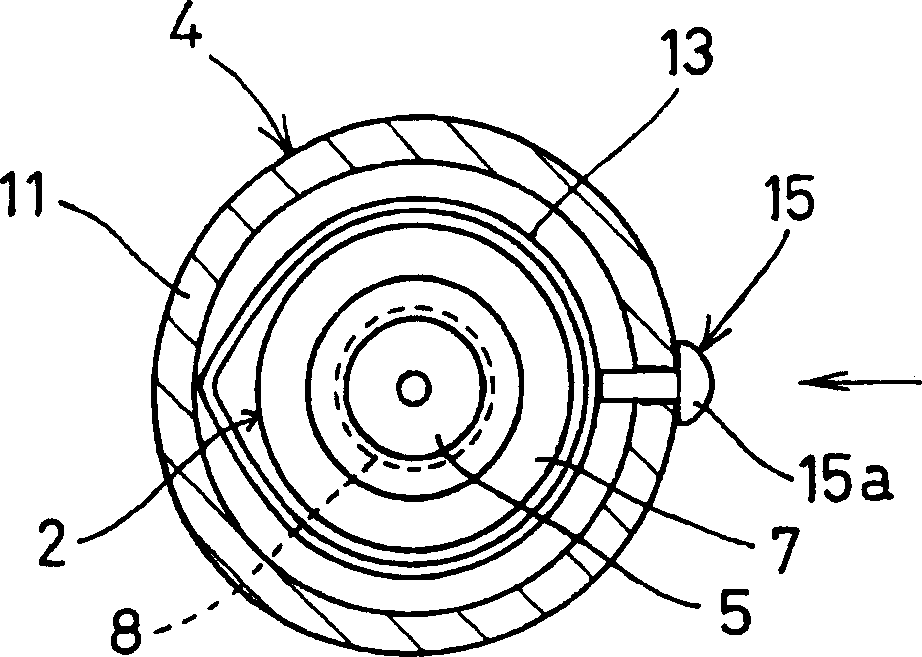

[0106] Figure 12 Embodiment 4 shown in (a) represents that in the above-mentioned embodiments 2 and 3, the elastic locking member 13, the bolt body 36 positioned at its top, the guide shaft 17 positioned at the center of the bolt body 36, and the elastic locking member 13 and a pair of interlocking parts 38 combined with the plug body 36, and the push-in parts 15a located at both ends of the elastic locking part 13 in the longitudinal direction are all integrally molded using elastically deformable hard synthetic resin.

[0107] Since the main parts of the structural components are integrally formed of synthetic resin, the assembly of the various structural components and the assembly operation into the cover body 11 can be greatly simplified, and the manufacturing cost can be reduced.

[0108] In the case of assembling the above-mentioned integral molded product into the cover body 11, as Figure 10 As shown in (a) and (b), the through holes 62 of the push-in parts 15a prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com