Thermal energy self-supply technology and equipment for carbon ammine production change system

A technology for transforming systems and heat energy, applied in the direction of ammonium carbonate/acid carbonate, etc., can solve problems such as unreasonable flow of gas and water, insufficient and reasonable use of heat, loss of heat energy, etc., to achieve Realize self-supply of heat energy and improve heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

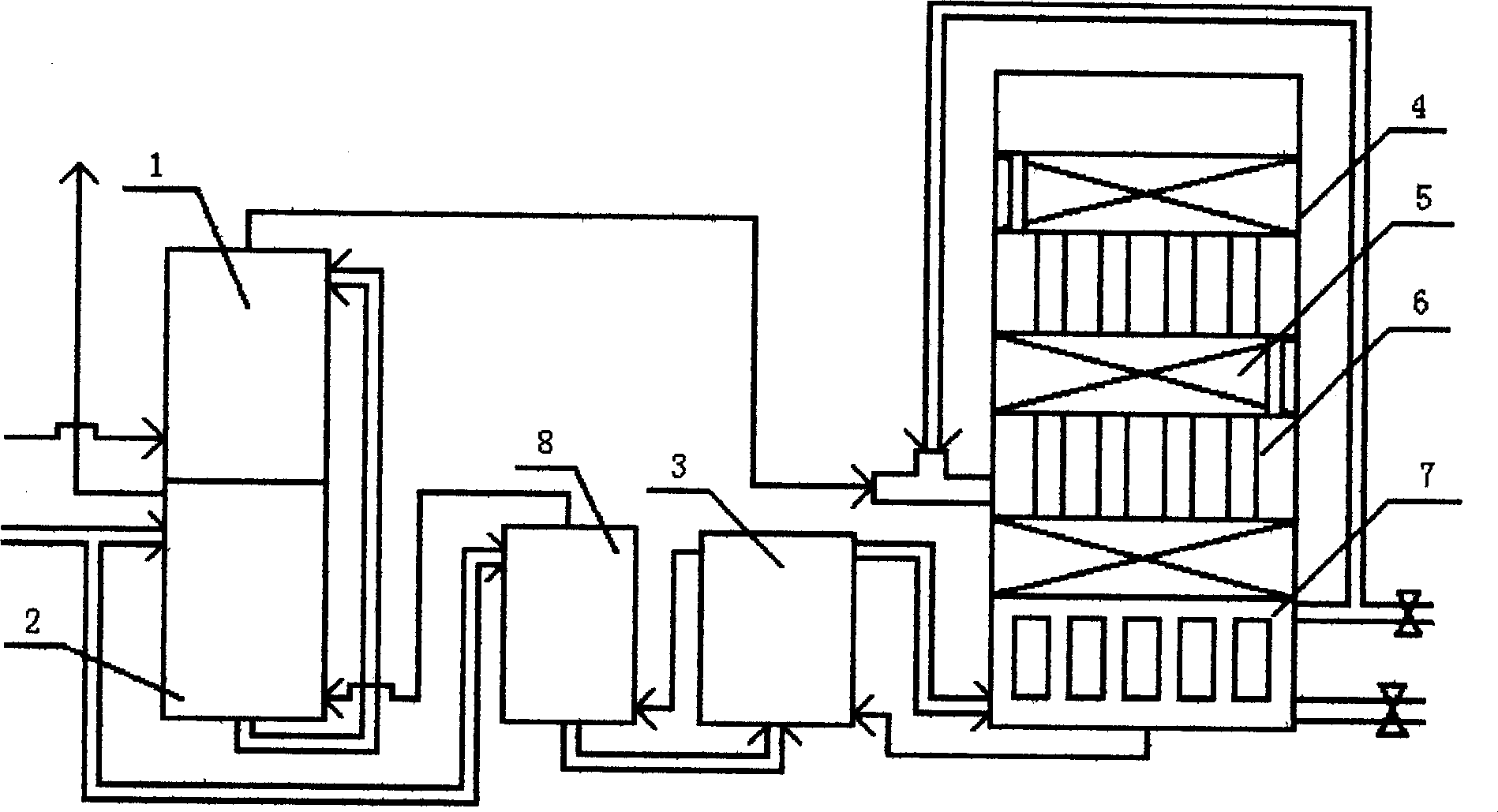

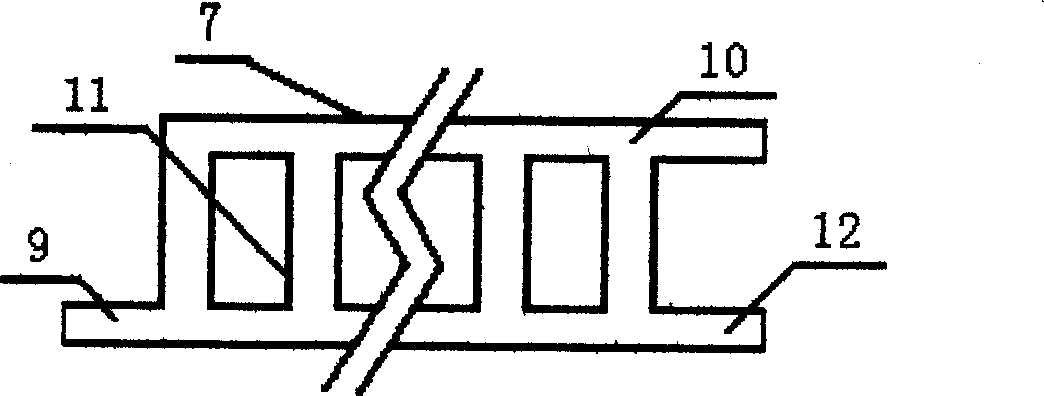

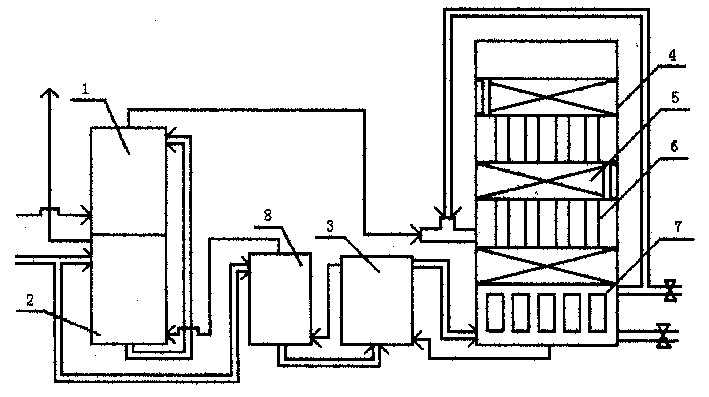

[0012] Such as figure 1 As shown, the conversion system is composed of a saturation tower 1, a hot water tower 2, a heat exchange device 3, and a shift furnace 4. The shift furnace 4 has more than two stages of contact with the coal seam 5. This embodiment is set according to the most common three stages. There is a preheating water tower 8 between the tower 2 and the heat exchange device 3. There is an internal heat exchange device 6 or a steam generation heat exchange device 7 below the catalyst layer 5 in the converter 4. In this embodiment, the bottom part of the catalyst layer 5 is the steam generation heat The exchange device 7, the bottom of the upper two catalyst layers 5 is an internal heat exchange device 6, the semi-water gas from the previous system enters the saturation tower 1, and the demineralized water from the previous system enters the hot water tower 2 and the preheating water tower 8 respectively. The semi-water gas mixture from the saturation tower 1 ente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com