Fowl eggs quality non-destruction automatic detection grading apparatus and process

A technology for damage detection and equipment, which is applied in the poultry industry, testing food, testing eggs, etc., to achieve the effect of good effect, high detection and classification accuracy, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

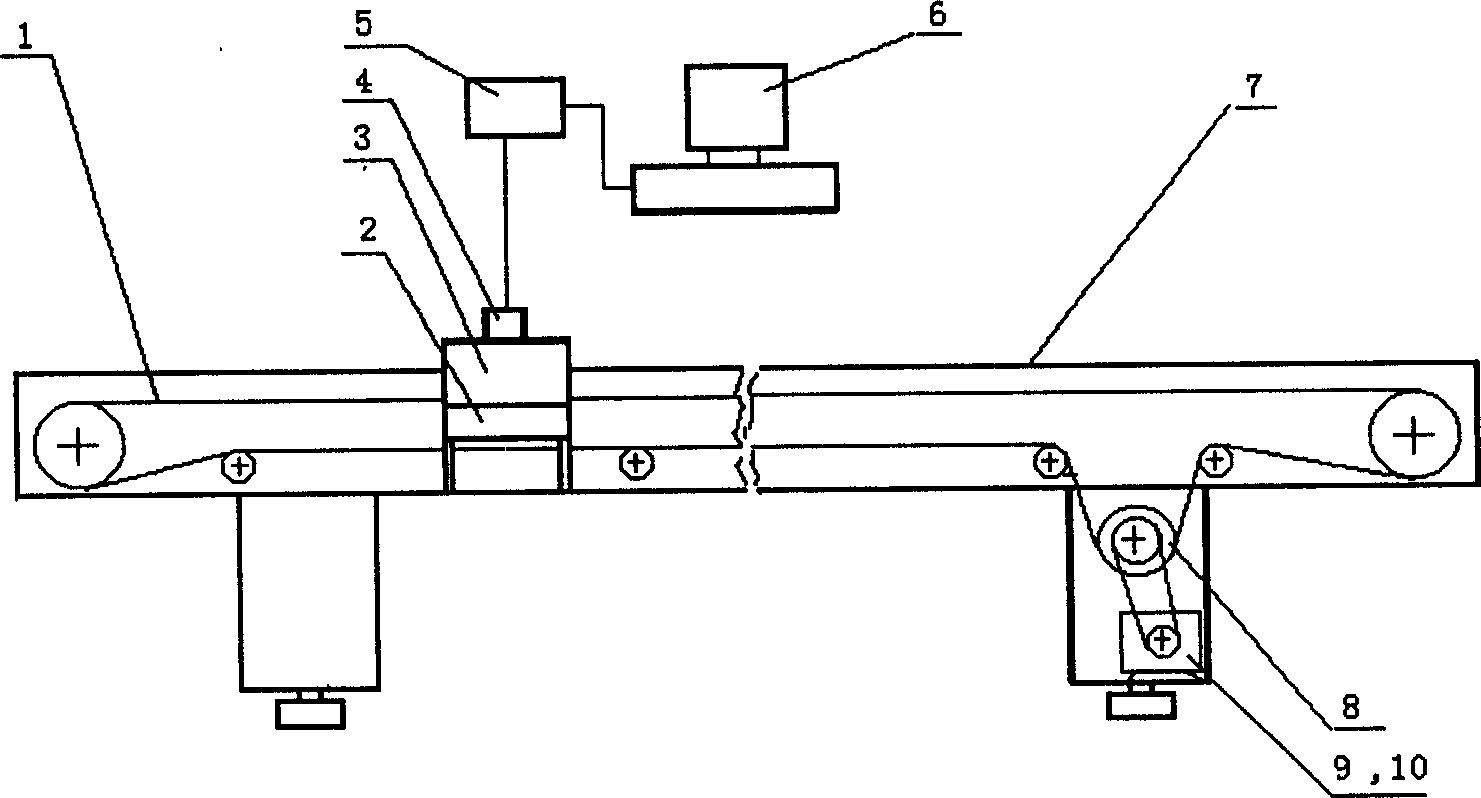

[0039] The duck egg quality non-destructive testing and grading equipment trial-produced by the present invention is as attached figure 1 The overall schematic diagram. On the automatic production line, the duck eggs are placed on the egg trays of the conveyor belt at a distance of 30cm, and the conveyor belt advances at a speed of not less than 30cm / s. The inspected egg first arrives at the damage detection position, and the program-controlled detection device for identifying damaged eggs collects the sound signal of egg knocking and analyzes and judges it, and then controls the egg damage sorting mechanism based on the judgment result. Therefore, the egg damage measurement and control software has the following functions: synchronously collect sound signals; analyze and process the collected sound data in real time to distinguish between shell eggs and damaged shell eggs; output control signals to the egg damage sorting mechanism according to the judgment results; provide wo...

Embodiment 2

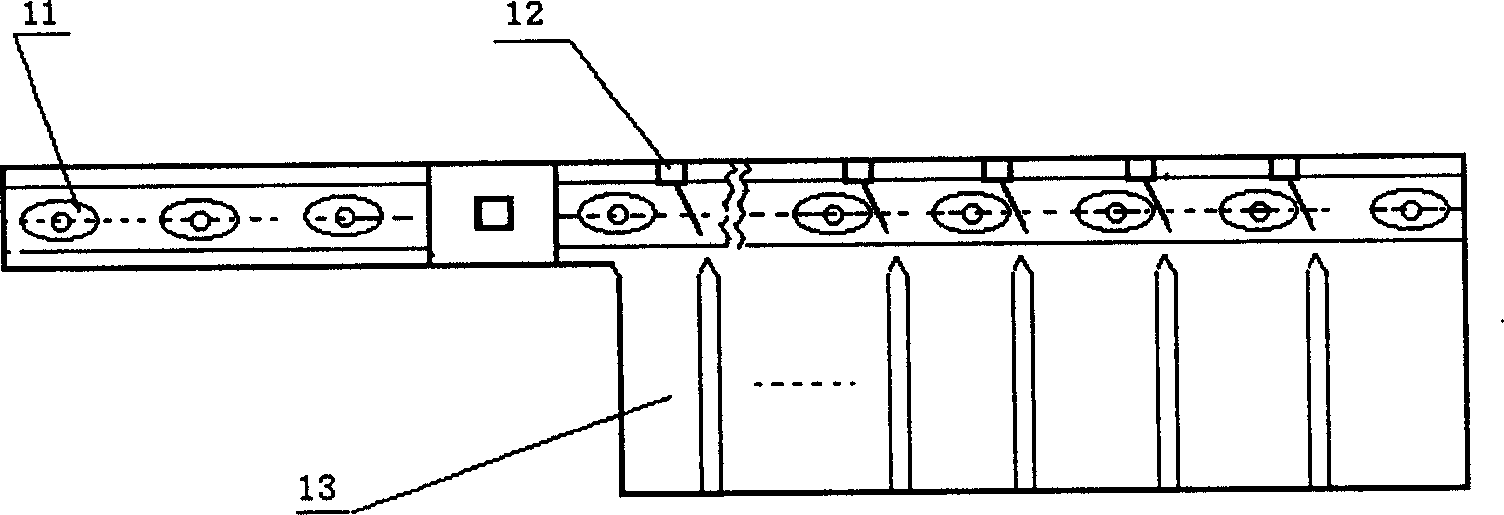

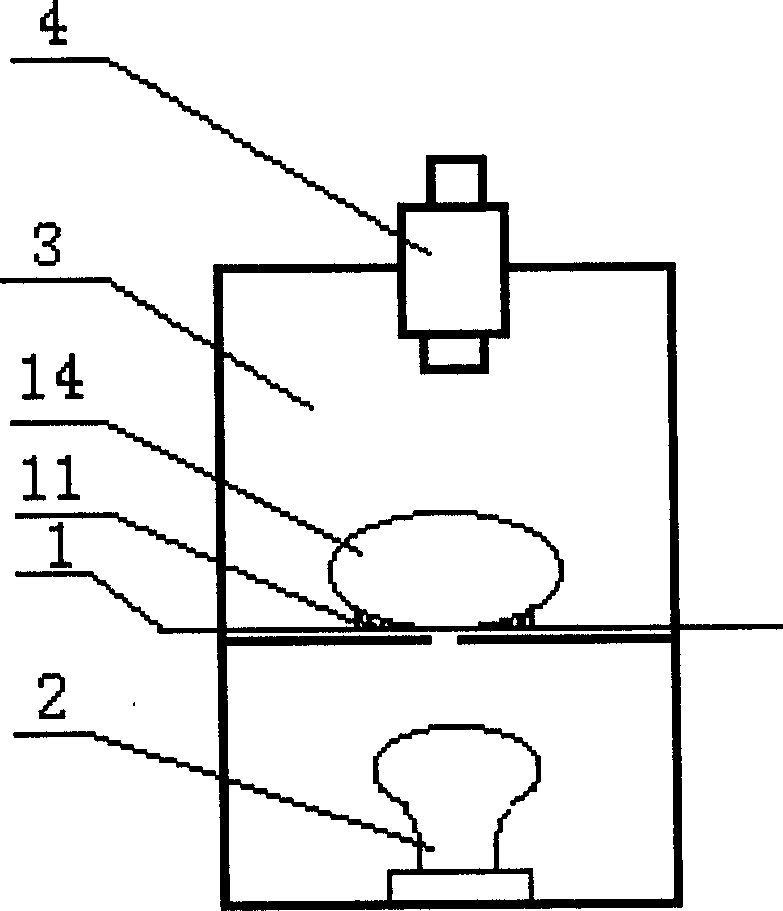

[0047] The egg image detection device is composed of a light chamber, a color camera, an image acquisition card, an industrial control computer, a digital input and output card, a PLC driving mechanism, and a grading mechanism. Such as Figure 8 shown.

[0048] Image acquisition card: Convert the video signal from the CCD into a digital signal recognizable by the computer, and send it directly to the internal video memory of the computer through the PCI bus of the computer and the DMA controller to complete the computer's acquisition process of the external image. Its technical features and indicators are as follows: color and black and white image acquisition; video input is standard PAL, NTSC or SECAM signal; six-way composite video input selection or three-way Y / C input selection; brightness, contrast, chroma, saturation software Adjustable; the maximum resolution of the image acquisition display is 768×576; it has the function of opening the window, the window can be squa...

Embodiment 3

[0061] In order to improve production efficiency, the image processing module needs to detect all egg quality parameters (including shell thickness, egg core color, size, and freshness) at one time when the egg freshness meets the conditions. For this reason, a parameter index is used to represent the final comprehensive coefficient of egg quality. Different indexes correspond to different classification situations.

[0062] Let dthick be the measure of shell thickness, and nthick the grade of eggs classified by shell thickness. If eggs are divided into 2 grades according to shell thickness, and the intermediate threshold value is valthick, then:

[0063]

[0064] Let dcolor represent the measurement of egg core color, and ncolor represent the class of eggs sorted by egg core color. If the eggs are divided into 3 grades according to the color of the egg core, and the intermediate thresholds are set to valcolor1 and valcolor2, then:

[0065]

[0066] Use dsize to repre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com